All about wall sheeting

Knowing everything about wall sheeting is useful for the owners of many private houses and public buildings. The dimensions of the facade profiled sheet, its types and colors can vary greatly. In any case, you should figure out the accessories for the corrugated board, with its options for wood and other styles, and how this material differs from the roofing sheet.

Peculiarities

Wall corrugated board is quite common on the market. You can find a similar product from any major supplier. Many customers try to use this material, and it is recognized as an almost universal solution. The designs are much lighter and thinnerthan when using concrete, brick or even dense hardwood planks. Despite this, the profiled sheet is very reliable and serves for years, it is distinguished by impressive hardness.

The stiffness is due to the special waveform and the significant size of the ribs. In some models, the metal layer reaches 0.9 mm. This significantly increases the stability of the decorated walls. Weight 1 sq. m ranges from 5 to 8.8 kg - both the steel grade and the used additional polymeric materials and dyes play a role. The minimum wave height is 2 cm (although material with waves of 3.5 or 4.4 cm is more in demand and more effective).

In favor of wall decking made of profiled steel, in general, they say:

-

optimal ratio of cost and quality;

-

no risk of fire;

-

comparative ease;

-

ease of installation;

-

excellent appearance that easily fits into any environment.

What is the difference from roofing?

It should be pointed out right away that the technical characteristics of the wall models are very high. And that's why they can be safely used for roofing... However, there is one caveat: increased strength is achieved due to increased gravity. Therefore, not all supporting structures can withstand such a load. You will have to carefully calculate at least the technical parameters of all contact points, from the very beginning to adjust the project along the walls and on the foundation.

The difference between wall and roof decking is their main purpose. Products of the "C" brand are used, as it is easy to understand, for the design of capital walls and various fences... It is worth remembering - in some cases, substandard material is used for partitions, which has individual dents, poorly stained places and other violations. Therefore, you need to very carefully select the finished product; with a fairly high quality and careful calculation of the loads, you can safely put the wall sheet on the roof, and the roof sheet as a fence.

The rigidity and strength of products for the wall is slightly less than for the roof... Basically, a material with a trapezoidal wave is placed on the roof. It should be lighter, which is not surprising. The quality of anti-corrosion protection of wall structures may be somewhat lower, because they are less affected by weather influences.

At the same time, material with a special mounting lock is extremely rarely placed on the wall and fence - other methods of connection are needed here.

Views

Decking can have a variety of colors. Its color is limited only by the range of colorants that meet the RAL scale or any other similar standard. Not monochrome are widespread, but design solutions that make out:

-

under a brick;

-

under the tree;

-

under the natural stone.

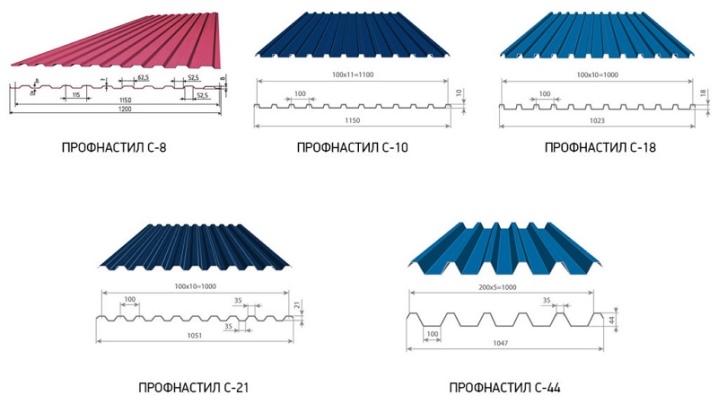

The brands of facade sheets show certain technological characteristics.Both the thickness of the metal and the size of the profiles are clearly illustrated. As already stated, wall panels are marked with the letter C. Immediately after it, write the height of the profiles, measured in millimeters... For example, a C10 product has waves of 1 cm.

The smallest rib height is 0.6 cm. The highest (for a serial product) is 11.4 cm... An increase in this indicator increases the bearing capacity - which, however, is achieved by making the structures heavier. It should be noted that the number of waves is often different.

Most in demand:

-

5;

-

6;

-

7;

-

8-wave sheets.

Steel thickness is indicated without correction for cover layers. Wall models of the profiled sheet always turn out to be thinner than the load-bearing versions. The marking necessarily includes information about the working width of the sheet. It is calculated as the total width minus the overlap areas.

The widest sheets in general reach 125 cm, of which 115 cm remains for the useful area.

For consistency with other figures, the maximum sheet length is also indicated in millimeters. For different manufacturers, it can be 12,000 or 10,000. In some cases, it is allowed to omit this parameter.

The type of protective coatings is designated as follows:

-

AC - a mixture of aluminum and zinc;

-

PE - polyester;

-

PUR - polyurethane;

-

AK - acrylic;

-

PVC - a combination of polyvinyl chloride and plastisol;

-

EOCP - zinc applied by an electrolytic method.

An insulating protective layer is applied on one or two sides. Among all brands of wall sheeting, the most in demand are the others:

-

C8;

-

C10;

-

C18;

-

C21;

-

C44.

Group C8 is suitable for facade and other walls... They use it when arranging fences and partitions. Such products are distinguished by excellent decorative parameters. The waves are repeated with a step of 8 cm. Both galvanized and polymer coatings are used, the usual metal thickness is 0.5-0.7 mm.

C10 is also used in roofing... This is a sheet with good rigidity, and on its basis you can build a fence up to 2.5 m high. The lathing step should be at least 80 cm. You can successfully imitate a simple wooden lining.

In some cases, this profiled sheet is taken to produce sandwich panels with polyurethane insulation.

Dimensions (edit)

The height of the corrugation at the wall profiled sheet ranges from 3.5 to 4.4 cm. The length of the sheet is almost unlimited (or rather, it is limited only by the possibilities of rolling production). The width of the C10 profiles is from 90 to 100 cm. For categories C18, C21 and C44, this figure is 100 cm. The thickness almost always varies from 0.55 to 0.7 mm.

Mounting

Wall sheeting accessories are very important.

You will need:

-

internal overhead corners;

-

initial planks;

-

strips for horizontal seams;

-

aquilons;

-

platbands;

-

connecting strips;

-

docking strips;

-

simple inner corners;

-

top and window drains.

Often the profiled sheet is attached to the wall for the purpose of insulation... Then the brackets are first mounted, and only after that the material itself is fixed by means of polyamide disc-type dowels.

So that the insulating layer does not suffer from the weather, films are used that stop the effects of wind and moisture.

The brackets are supplemented with guides in the form of the letter P; their fastening with rivets allows you to align the walls and ensure air flow. The next step is to attach horizontal profiles to the guides, also in the form of the letter P.

Installation of wall sheeting on the facade is usually carried out using self-tapping screws, supplemented with rubber gaskets... The internal and external cladding on the initially insulated panel is laid out differently. They begin with the design of two layers of roofing material for waterproofing the foundation horizontally. Next, the lower guide profile is fixed with anchor screws of a universal type. They are mounted vertically into it and the racks are fixed, which allows you to create a frame.

The comment was sent successfully.