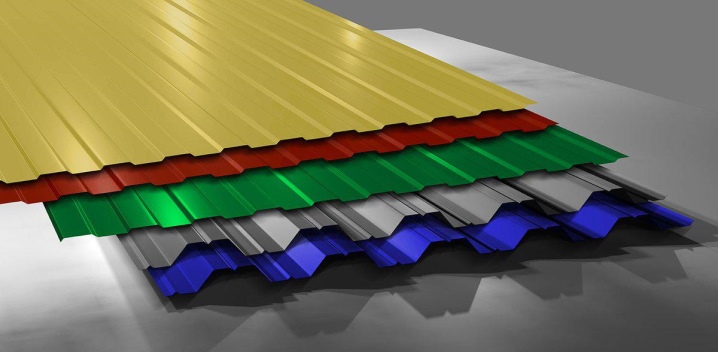

Polymer coated profiled sheets

Polymer coated profiled steel sheet has excellent performance characteristics. The expected service life of such a material is 50 years or more. With excellent bearing capacity and budgetary cost, this corrugated board belongs to the category of the most demanded building materials. These qualities have been achieved thanks to the development of modern technologies.

Peculiarities

Polymer-treated metal profiles are made of steel in rolls, pre-coated with a protective colored layer.

In production, the quality of the machines is very important, since the protective coating is usually applied in a thin layer and can easily be damaged when bending sheets.

Usually, the front side of the profile sheet is coated with polymers, and the inside is treated with a special varnish.

Polymers are applied to metal substrates using different methods, but the process is essentially the same. Galvanized steel is degreased and prepared for painting. The painted sheets are sent to the oven for polymerization and fixing of the applied protective layer. In addition to the material with one-sided coating, the factories produce sheets that are more decorative and durable, with double-sided processing.

Views

Several polymer coatings are widespread in Russia.

Polyester

The most affordable and demanded type of coating that is resistant to UV rays and fading. Serves as protection of metal surfaces from corrosion and copes with fluctuations in outdoor temperature.

The main drawback of this type of coating is that the polyester layer is minimal in thickness. The glossy layer can be easily scratched even with a slight impact. A more practical option would be to purchase profiled sheets with a matte polymer treatment.

Matt polyester

Such a profiled sheet is distinguished by a rough surface, due to which light is scattered, and the coating loses its shiny gloss. Matte polyester is applied in a dense layer. But with an uneven texture of the polymer surface, it is difficult to accurately determine the thickness of such a coating.

The increased density of the polymer layer contributes to an increase in the service life of such a profiled sheet. Another distinguishing characteristic of a matte polymer coating is the ability to give it a similarity to stone, wood texture and other natural materials.

Pural

Polymer coating to protect the sheet from various types of damage and enhance its aesthetics. It is made of polyurethane with the addition of acrylic and polyamide. The profiled sheet under a layer of such material withstands the effects of substances with a chemical structure, including acids.

This type of coverage is recommended on the seaside, in areas with salty and humid air.

Pural-coated galvanized steel easily copes with temperature changes and does not deteriorate under UV rays, although the colors fade a little over time. The only drawback of such material is the cost of processed profiled sheets. They are much more expensive to customers than similar options with a polyester layer.

Plastisol

The coating, 80% consisting of polyvinyl chloride (PVC) and 20% of plasticizers, is applied to the metal with a layer of 200 microns, giving the corrugated board the greatest resistance to any impact. This is the most durable coating possible.

At the same time, corrugated board of this type is not suitable for use in hot weather conditions, as it has low temperature endurance.

Besides, Plastisol is prone to fading, therefore it is recommended to paint it in light colors. The protective coating with plastisol is distinguished by a decorative textured surface, which gives the profiled sheet a matte and anti-glare effect.

Life time

PE (Polyester)

With proper installation, the service of a roofing sheeting with a polyester coating will be 25 years or more. In this case, the entire service life of the color qualities will remain unchanged. This applies to a glossy type of coating. And the matte version will last up to 40 years.

Plastisol

UV resistant coating that will hardly fade. Roofs and facades made of plastisol sheets will not change their color for 40 years. Usually, PVC-coated profiles are preferred in the northern regions, in the realities of a harsh climate, as well as in industrial areas, especially for chemical enterprises. In addition, plastisol is indicated for use when the likelihood of external influence of a mechanical nature prevails, for example, if the area is characterized by precipitation in the form of hail, dust storms, and more.

PVDF

Retains metallic material even under aggressive conditions. This type of corrugated board is optimal for roofing and finishing of buildings in cold climates, industrial areas, in coastal areas and near busy roads.

Pural

The service life of such a corrugated board is 5 decades. It is resistant to mechanical stress, which can be judged by the thickness of the coating layer, corresponding to 50 microns. Therefore, this corrugated board, in particular, is used in harsh natural conditions, in areas where many industrial enterprises are concentrated. Due to its high cost, it is usually used for roofing and facades. Pural polymer coating is available in glossy and matte finish. The matt protective layer acquires resistance to dirt over time.

The comment was sent successfully.