Features of professional sheets НС44

The article briefly describes the features of professional sheets HC44. Attention is paid to their size and weight, bearing capacity and other technical characteristics. The main differences from the C44 profiled sheet, data on the areas of application and installation tips are given.

What is it and how is professional flooring done?

Profiled metal sheets have been used for a very long time for a variety of tasks. This technology has been worked out to the smallest detail today and can be combined with the use of high-quality protective coatings. But that is precisely why it is so important to understand how the HC44 professional sheet differs from other options. And in particular, what are its differences from C44, are these materials interchangeable, and to what extent. The letter C shows that we are talking about a wall profile, but the HC marking - speaks of greater versatility.

She points to increased strength achieved by the introduction of special stiffeners. They are located both in the upper and lower planes of the corrugation. As a result, a material is obtained that can withstand loads not only in statics, but also in dynamics. An important circumstance is also the formation of special capillary grooves on the sidewalls.

They increase the tightness of the structure and eliminate the risk that something foreign, including moisture and dust, gets inside the assembly.

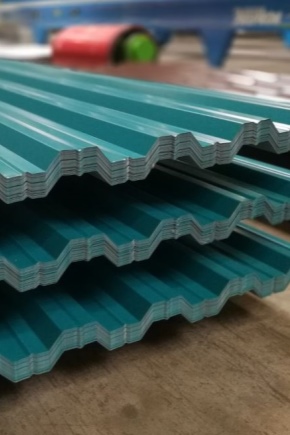

Professional flooring НС44, like other similar materials, is obtained on rolling equipment... A special unit of the production line is responsible for the unwinding of steel coils in the most efficient way possible, in sync with the operation of other machines. Importantly, only hydraulic shears of a special design can cut the sheets to size. Conventional flat scissors will not be able to provide a sufficiently high quality cut. The final product, as a rule, has a bright saturated color, but colorless products are often produced by agreement with consumers.

Profiled sheets are usually rolled cold way... This minimizes unwanted changes in the molecular structure of the steel. The initial coating is often a combination of zinc and polymer. However, the use of alumopolymer mixtures is no less popular with manufacturers.

The choice between these options is determined by engineering considerations.

In favor of high-quality corrugated boarding are evidenced by:

- excellent bearing capacity;

- high mechanical strength;

- comparative ease (which is important not only during transportation, but also during unloading, loading, when moving around the construction site);

- excellent resistance to corrosion due to correctly selected and applied coatings;

- visual appeal of finished products.

Specifications

The bearing capacity of the HC44 corrugated board is higher than that of many other brands of the universal profile... Only certain types of such products can replace and surpass it. Therefore, you can successfully take this profiled sheet for high barrier structures with significant windage, and for the design of a roof with a low slope. Depending on the specific brand of sheets, their sizes differ. First of all, the thickness is different - for galvanized profiles it can be 0.55, 0.7 or 0.8 mm. Accordingly, in this case, the weight of 1 m2 of usable sheet space will be:

- 6,6;

- 8,3;

- 9.4 kg (the very same working width of sheets in any type is identical and is exactly 1000 mm).

Popular manufacturers

You can buy HC44 category metal products in all hardware stores and in specialized markets. But it is much more profitable to buy them directly from the manufacturers. Of course, the thicker the material, the more it weighs, and the more significant the price will be. Also, the cost is influenced by whether a polymer coating is used or not. Do not think that only abroad they produce an impeccably high-quality profile; domestic companies have mastered this skill just as well.

A striking example of this is the products:

- LLC "Profmodul";

- "Stelex";

- TPK;

- Europrofile;

- NK-Siberia;

- "Profmetall";

- Spetsmetal;

- AMK-Group;

- ANEP-Metal.

Applications

Professional sheet НС44 quite suitable as a roofing material. And in this capacity it is used quite often. Corrosion resistance is very important in most of the territory of our country. But the same property motivates to use it in the construction of fences and other enclosing structures. And the increased strength creates optimal conditions for the use of corrugated board as formwork, primarily for strip or monolithic foundations.

Installation tips

It is very important to connect the sheet with the crate and with other sheets in accordance with all the rules.... Only in this case is a long period of operation and stability of all design qualities guaranteed. Galvanized self-tapping screws proved to be the best. There is no need to drill holes for them in advance, and at the same time, the strength of the joint is quite optimal. Fasteners are used only in the lower corrugation segments.

Between self-tapping screws, as well as between rivets, there should be a gap of no more than 250-300 mm. Otherwise, the mechanical reliability of the assembly is questionable. It is extremely important: it is absolutely impossible to weld a profiled sheet. The welds are bound to weaken the entire structure, despite the efforts of the welders. It should be remembered and about waterproofing, about vapor barrier of the substrate - although the material itself is impervious to water and steam, additional protection definitely does not hurt.

НС44, according to the technical standards of the manufacturers, is placed on the crate with a node pitch of 500-1000 mm. On the roof, this step is determined by the slope, and on vertical surfaces, by the resulting load. It is useful to turn to professionals in order to calculate all the side acting factors as reliably as possible. If the profiled sheet is mounted on the roof, it is impractical to walk on it until it is finally fixed.

To make the slope stronger, wind bars are used.

The comment was sent successfully.