Features of galvanized corrugated board

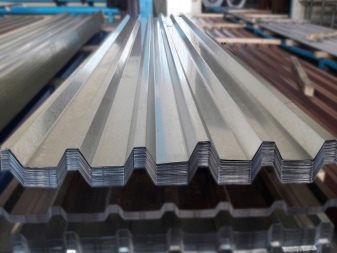

Sheeting or profiled sheet is an irreplaceable and most suitable material for outdoor use (covering roofs, fences, fences, sheds) and is used in all parts of the country.

At the moment, profiled sheets occupy the first place among the materials that can be used to cover the surface.

Pros and cons of corrugated board

Positive sides:

-

low cost of goods and availability to almost all segments of the population (if a large manufacturer makes a purchase, then the roof will get him practically free of charge, because the material is cheap compared to others);

-

rigidity and high strength of the product, which allows it to withstand the most difficult household items or a person working on a hill;

-

quality proven over the years - the material will last about 50 years and, under good conditions of use, will remain for many years and will remain for other residents;

-

conciseness and lightness - the profiled sheet is not heavy, as one might suppose, looking at the photographs, but light and even conveniently portable material;

-

a huge assortment when choosing a color scheme, there are almost all shades;

-

it is convenient to use and does not require maintenance for itself (the minimum action is to clean it with water or a broom from the formed sediments, organic residues).

Negative sides:

-

outdated look - some builders are not impressed by the look of the material, and they consider it impractical and not meaningful for the present;

-

alternative - if 10 years ago there was only such material on the country's markets, then at the moment the choice has expanded, and the demand of buyers has changed, respectively, and the supply;

-

gradual disappearance - due to the development of technologies and the improvement of the technical world, new varieties of roofing and decking of other surfaces appear, so the profiled sheet is not very popular;

-

rust - the profiled sheet goes through many treatments, useful coatings accumulate on it, which do not allow the material to deteriorate, but this is metal, and no process will stop the slow aging process of the material.

Applications

Galvanized corrugated board is used in a wide range of household and factory affairs; this material is especially popular among large manufacturers in Russia.

The profiled sheet is used to create fences, fences, flooring of roofs of houses.

A painted sheet looks best (the employee himself can choose a palette of colors) on the surfaces of buildings, because it is thanks to the pleasant color that the interior image of the room immediately becomes more pleasant.

The material is versatile, and a professional will definitely find a use for it:

-

for the construction of temporary or permanent fences;

-

for wall cladding and their construction;

-

to install fences;

-

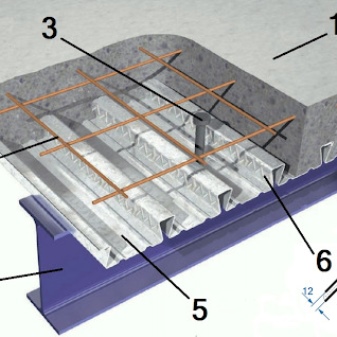

corrugated board helps with the construction of fast buildings (installation);

-

used as a permanent formwork.

The galvanized profiled sheet is strong, reliable, durable, has a wide range of colors and all kinds of shades, requires minimal personal care, is easy to transport and store, resistant to ultraviolet rays, changes in temperature, humidity, mechanical damage, lightweight and convenient.

When working with corrugated board, you can complete household (household) tasks, beautifully equip the backyard of the house and make excellent repairs without expensive materials, but with a design pleasing to the eye.

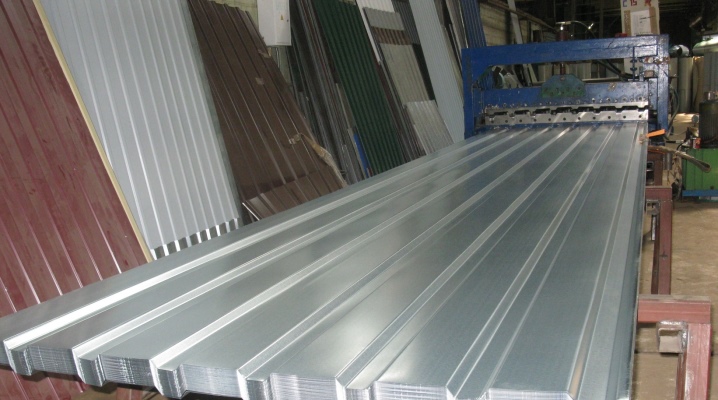

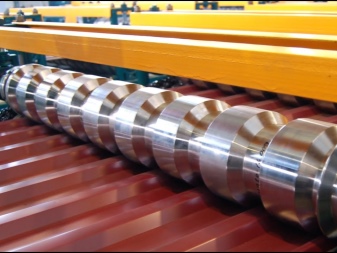

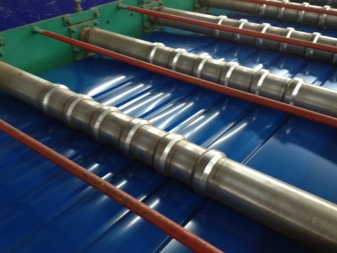

How is decking made?

First you need to consider the machine on which the material itself is made.

The machine includes the following parts:

-

control panel (the main part of any tool that allows you to control the machine from a distance, stop it or start it at a convenient moment);

-

unwinder (stretches the metal, thereby making it possible to properly process the material);

-

cutting device (special processing and cutting of metal objects);

-

design mill (at this stage, plastic deformation of the presented object takes place).

Two methods are commonly used: sequential (combined) and simultaneous.

Both options have their own advantages and disadvantages; the first case is usually used in production.

We turn to the most important and interesting thing - the sequence of manufacturing a profiled sheet.

-

A roll of polymer protected material is placed on a processed unwinder. With its help, the metal is evenly distributed over the surface.

-

It comes down to the forming machine, where the end of the sheet must go through the rolling mill, from where it will go to the next stage.

-

Thanks to intelligent technology and a control panel, the machine is pre-set programs and norms for length, width and rolling speed of galvanized sheet.

-

Then the operator clicks on the "start" button. The metal sheet begins to slowly move towards the goal - processing going through all of the above stages.

The process does not take much time with good modern equipment and professional workers.

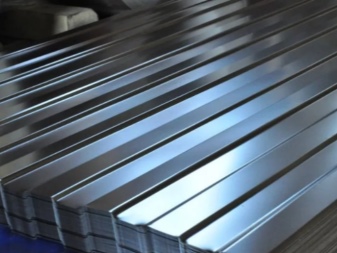

Profiled sheet specifications

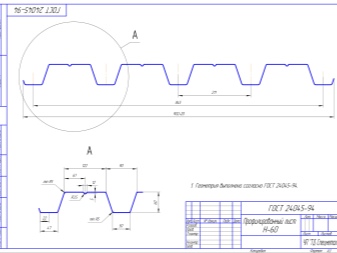

Regulatory characteristics are in accordance with GOST.

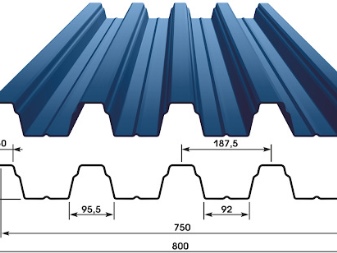

Dimensions (edit)

The dimensions of the profiled sheet are different and depend on the desired coverage object. Roofing (H57) is about 75 cm wide, H60 - almost 85 (84.5), and H75 - 85 cm.The load-bearing ones reach 1-3 m in height.

When purchasing a profiled sheet, you will notice that there are two material widths on the label. This is accepted, because the sheet is always different depending on the number and structure of the waves.

A standard width of 1000-1200 mm (1x1250x2500) is used, but due to galvanizing, processing, completely different measurements are obtained. The bearing corrugated board reaches 6 meters in length.

Weight category

For to calculate the exact weight of the corrugated board, you need to find out its area, width and, accordingly, length. Always pay attention to additional factors that affect the weight category: the coating and its type, the distance between the waves formed, the sheet itself and its technical characteristics and the auxiliary parts in which the products are stored (wrapping paper, cardboard, pallet).

There are special norms for such a weight, 1 m2 weighs about 4-8 kg, depending on the type of material.

The sheet thickness usually varies from 0.4 to 0.8 mm.

Life time

As mentioned earlier, a profiled sheet can be suitable for up to 50 years, however, a number of exceptions should be stipulated here.

If large precipitation (hail, heavy rain) hits the material, the material may not withstand and deteriorate (formation of holes and cracks).

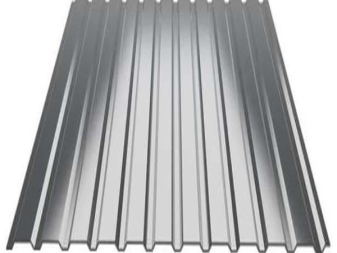

Species overview

Galvanized corrugated board is wall, roofing and load-bearing.

Stenovoi

The product with the smallest profiling. Any sensible specialist has his own special marking of wall sheeting, which distinguishes him from other companies and organizations.

The height of this type of material varies from 8 to 21 mm.

It is worth paying attention to the fact that the wall profiled sheet is of high quality and sail, it is also often subjected to wind load, which can be dangerous for the structure, it can be dealt with by choosing a sheet with an increased wave or arranging a strong frame base.

Roofing

Always wave, due to which the throughput increases, which is the main feature of the roofing sheet.

Designations are identical with wall, letters and numbers. For example, PK-35 is 35 mm long. Roofing starts from 20 to 100 mm (this is another advantage of the variety). Used for roofing.

Carrier

The sheet category starts from 75 to 100 mm. They are used to cover reinforced concrete hills. Stamping is used for reinforcement on the main profiled sheet.

For a fence, this is an excellent solution, because it is he, like no other, that is suitable for strong, beautiful and reliable protection.

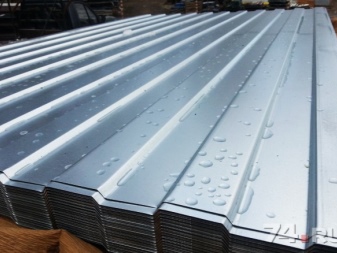

Profiled sheeting is also available with a polymer coating. Polyester provides additional anti-corrosion protection.

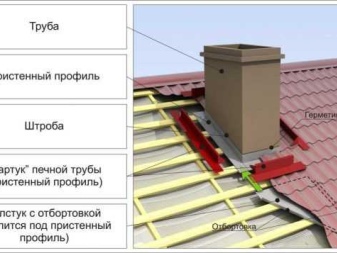

Installation tips

Having bought a special sheet, it is necessary to correctly dock it with the pillars or the surface on which it will lie. It's not as easy as it sounds, but a little patience and quality work will lead to a good result and a nice look.

Stages of correct flooring

The first step is to install the eaves, fixed with bolts and screws. Further, it is worth protecting the affected area from water or other liquid, because the corrugated board, although it is treated with special agents against rust and decay, but, like all metals, is prone to corrosion with subsequent unsuitability for use.

When laying on the sides, joints and gaps are formed, they must immediately be glued with seals (available in all hardware stores and not very expensive) and add sealant or mastic to them.

The order of stacking the sheets is not so important, you can start laying both on the right side and on the left, most importantly, from the ends of the roof or the desired coating, and not from the middle, because the work should go evenly and according to the instructions.

Slopes can occur when laying on shallow areas, in which case it is important to overlap in one wave without gaskets that can harm the surface.

The profiled sheeting is laid with an overlap (width 20 cm), that is, from bottom to top, so that the edge of the bottom sheet is placed under the upper edge.

When laying any material, it does not matter, a profiled sheet or other product, it is worth securing the master with special fasteners and placing fences so that he does not fall and damage his health.

The corrugated board has justified its stability and importance as a material for covering all kinds of surfaces.

In what cases to use galvanized corrugated board, see the video below.

The comment was sent successfully.