What and how to paint the corrugated board?

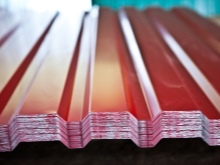

Decking is a popular material that is used in many jobs. It is practical, reliable and easy to work with. It is often necessary to paint the corrugated board, for which special types of paints and varnishes are used. We will talk about them in this article.

When is staining required?

Painting the corrugated board in a different color is necessary in several cases. Let's consider which ones.

- You will need to paint over the base if there are scratches, chips, deep damage on it due to inaccurate transportation or storage. It will be possible to get rid of these defects on our own by means of a well-chosen coloring composition.

- Painting is indispensable if the cheapest type of galvanized profiled sheet was installed, on which a protective layer is not provided. In this situation, it is possible to paint the base, thus improving the quality characteristics of the material.

- If you paint the corrugated board with high quality and according to all the rules, then due to this, it will last much longer and turn out to be more practical. We are even talking about materials that have already served for 10-15 years.

They also resort to the processing of corrugated board if you want to refresh its appearance, repaint it in some new shade.

Funds overview

To paint sheets of corrugated board, it is advisable to use special types of paints. Alkyd and acrylic compounds are suitable for such work. They fit well on sheet material and are securely held on it. Let us consider in more detail what features and characteristics the paint and varnish mixtures of different types have.

Alkyd polyester enamel

Galvanized corrugated board can be coated with special alkyd polyester enamel. Similar compositions are presented in rich colors. In terms of their quality, they are in no way inferior to coatings containing polymer components. By itself, the enamel in question can give the sheet material all the necessary properties.

Alkyd polyester enamel is practical. She is not afraid of temperature jumps. A high level of humidity is also not capable of harming such a coating on a corrugated board. However, over time, such a paint and varnish composition gradually loses its former elasticity indicators.

Small cracks begin to appear on the painted surface, gathering into a thin mesh. This reduces the protective performance of the existing coating.

Acrylic water-dispersed emulsion

The specified coloring composition in many cases is used for laying on metal. Such paint can be applied on almost any type of corrugated board as easily and seamlessly as possible. At the same time, it demonstrates high indicators of elasticity, looks rich and high quality. Acrylic emulsion on a water-dispersed basis is characterized by a longer period of operation than the above specimen, suitable for processing corrugated board.

The considered mixtures tolerate possible expansion of the base material, which occur due to temperature jumps, without problems. In addition, water-based acrylic emulsions are not susceptible to cracking. The main disadvantage of such a material is that the base has to be prepared for a long time and carefully before it is applied. Such procedures cannot be neglected.

Acrylic primer with rust converter

If you need to paint high-quality corrugated board, the state of which cannot be called ideal due to the appearance of rusty foci, then here you need to use a repair solution. For this, it makes sense to choose a special acrylic primer, the content of which contains special corrosion converters. These solutions primarily perform an important protective function. They are used in combination with other paints and varnishes. Standard paint will not work for rusty corrugated board surfaces.

Acrylic primer with rust converter can be laid on the surface of the corrugated board in several layers. Only at the end of this stage can a certain type of decorative paint be applied. Due to such manipulations, the material is well protected from corrosion, and also acquires an attractive appearance.

Painting methods

Decking, like any other material, must be painted correctly. There are several methods on how to paint such a base with high quality. Let's get acquainted with the most relevant ones.

- Powder method. Usually this method is implemented on an industrial scale for painting various surfaces. In this case, products are used that contain rubber and a specialized coloring pigment that can enhance the base color. Due to the uniform application, the material acquires the necessary shock resistance and moisture resistance, its protection against negative external factors is noticeably increased. In order to polymerize the surface, a special technique of heating the corrugated sheets is used.

- Electrostatic method. This method of painting involves applying charged particles to the surface of the sheet material using a convenient spray gun. In this case, the particles create the required electric field. Thus, a more economical consumption of the dye composition is increased. The described method is perfect for the highest quality and uniform application. If we are talking about surfaces that are distinguished by a more complex relief, then they will be slightly more difficult to process.

- Airless method. Galvanized sheet material can be processed using a spray gun equipped with a special nozzle. The latter will reduce the pressure on the particles, thereby reducing the likelihood of the formation of a coloring mist. This technique is also often used when laying the emulsion on flat surfaces.

- Pneumatic method. The pneumatic method is often used to paint the corrugated board. It is ideal for home use. Due to the compressed air, the paint and varnish composition flies out in a uniform layer, and then it is well distributed on the surface of the base. This technique is considered very popular, it is suitable for processing roofing materials, fences, as well as decorative interior components.

When choosing a certain option for coloring the corrugated board, it is very important to take into account both its type and the parameters of its relief. The desired thickness of the ink layer must also be taken into account. The best solution for home use is pneumatic technology.

Preparation

If high-quality painting of corrugated board is planned, it must be properly prepared in advance for all operations. This stage plays a very important role, so it cannot be neglected in any case. Preparatory work involves a number of activities.

- First, it is important to thoroughly clean and degrease the surface of the corrugated board. Good organic solvents are recommended for these procedures.If there are foci of rust on the base material, then it is best to remove them by means of effective alkaline solutions, and clean them after that.

- Another important step is drying the surface of the corrugated board. It will be necessary to remove all excess moisture and moisture from the material. The corrugated board must be ideally prepared for further processing with the coloring composition. If you apply an emulsion and lay it on a damp base, then the paint subsequently runs the risk of cracking or starts to roll.

- The next stage of work is the application of a primer. It will serve as the basis for the dye solution.

It is necessary to prepare the corrugated board for painting very carefully and scrupulously. If you treat this stage of work with disdain, then painting will not allow you to achieve the desired results.

Fundamental rules

Consider a few basic rules regarding painting corrugated board on your own and at home.

- The first step is to find the right paint. It should be borne in mind that solutions in a spray can are best suited for handling small imperfections on the surface of the corrugated board. If we are talking about impressive areas, then for this it is most convenient to use a spray gun or brush of the appropriate size.

- The painting process must be carried out in special clothing. Be sure to use gloves. If a spray gun (spray) is used for application, then you need to stock up on glasses and a protective mask.

- To avoid scratches as you move along sheet materials, you must wear special non-slip shoes with a soft sole.

- Coloring the corrugated board turns out to be the most convenient and hassle-free if you turn to the combined staining method. This refers to a combination of airless and pneumatic paint spray. This method is especially convenient in the presence of a perfectly straight surface, because to process bases with a relief, you will need to stock up on a brush or a wide roller.

- Before painting the corrugated board, be sure to pay attention to the temperature of the selected paint. It should be between –10 and +45 degrees Celsius. The time interval for complete drying of the coloring layer at an ordinary temperature of +20 degrees will be from 12 to 20 hours.

- If necessary, the paint will need to be pre-diluted with special solvents. This is necessary for the composition to acquire the desired viscosity. As solvents, as a rule, ethyl acetate, butyl acetate, xylene and other mixtures of a similar type are used.

- For high-quality application of the coloring composition, it is recommended to hang the sheets of corrugated board so that they are in an upright position. So it will be much more convenient to paint the material from both the front and back sides. The most convenient way to do this is to use wire hangers. The sheet material should be fixed, maintaining a distance of 2 to 3 m from the entrance to the room where the work is being carried out.

- If a tribostatic spray is used, then it will need to be set up, maintaining a distance of 20 to 35 cm from metal surfaces. When using a powder paint mixture, it must be laid in even parallel layers.

It is not difficult to paint the corrugated board with your own hands on both sides. If you act carefully and use quality paint, you can achieve very good and long lasting results.

The comment was sent successfully.