How do I refill a printer cartridge?

These days, most PC and laptop owners have a peripheral such as a printer. It is important to bear in mind that most often such devices are purchased in order to save money. Taking into account all the nuances - and, in particular, the cost of consumables - the answer to the question of how to refill a printer cartridge at home with minimal costs is relevant.

Fundamental rules

The need to replace cartridges in the printer will be indicated by obvious flaws in the printing process, which will be noticeable almost immediately. In this case, we are talking about a sharp deterioration in the quality of the printed material. In such situations, there are several options for solving the problem, namely:

- purchase new cartridges;

- contact specialists;

- refuel yourself.

This is true for both inkjet printers filled with ink and laser printers with powder toner.

It is important to take into account that a fairly wide range of consumables for the equipment described is now on the market.

It is often difficult to understand such a variety. So, refueling provides:

- knowledge of the printer model;

- the correct choice of ink or toner;

- knowledge of the equipment design and the algorithm of actions.

The type of filling material will directly depend on the category of the printer or multifunction device. It should be noted that inks for inkjet devices are divided into two types: made on the basis of dyes or on a pigment basis. At the same time, certain and rather stringent requirements are imposed on the two indicated varieties, namely:

- maximum resistance to moisture;

- no fading;

- maximum picture clarity;

- drying speed.

It is worth emphasizing that Dye-based inks are virtually free of particulate matter as their function is performed by water. In the situation with the pigment type, this role is assigned to small particles of rather solid substances.

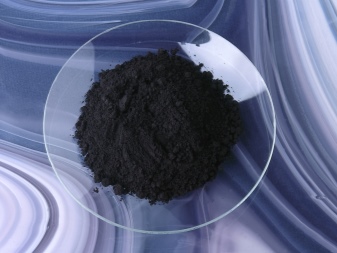

When refilling cartridges for laser devices, a special magnetic powder called toner is used. It is made from different polymeric materials. The list of parameters by which this consumable is classified includes:

- print color (toner can be either black or full color);

- production technology;

- the type of polymer used as raw material.

However, in practice, the most significant point is the division of the dielectric filling material into magnetic (DM) and non-magnetic (DN).

This refers to the presence and absence of iron oxide in the toner.

Instructions for refilling printer cartridges

The essence of the problem in the overwhelming majority of cases boils down to the fact that manufacturers install so-called demo cartridges into new peripheral devices. They differ in a small resource and quickly cease to fulfill their functions. In such situations, some users purchase new cartridges, which often cost more than the device itself. It is worth noting that, according to available information, HP has a large profit precisely from the production and sale of the described elements of printers and MFPs... It is important to consider that this is due to low cost.

With all this in mind, it is worth considering how to properly refill the inkjet and laser printer cartridge yourself. It is immediately necessary to focus on the fact that this process has a number of features and is more complicated than it might seem at first glance... At the initial stage, you should decide on the model of both the gadget itself and the accessories for it. It will be useful to study the materials on the features of the equipment.

After you have purchased ink or toner (depending on the type of printer), you need to equip a place to perform all the necessary manipulations. It is important to remember about safety precautions, taking into account the chemical properties of the filling materials.

Inkjet

Today, these types of devices remain the most common. This is largely due to the ability to print color images at minimal cost.

However, it is worth considering that with the minimum cost of the printer, you will quickly have to face the need to purchase new and expensive cartridges.

That is why the topic of refueling these elements with your own hands is relevant. This will require a specific list of required materials and tools.

- Ink corresponding brand, sold in bottles of different sizes.

- Syringes... Experienced users recommend that you select them commensurate with the volume of the cartridge itself.

- Scotch, with the help of which, after completion of the refueling, it will be necessary to seal the holes in the case. By the way, many cartridges have stickers that do a good job of this. However, after several refueling, they become unusable.

- Oilcloth or newspaperthat will need to cover the workplace. It is also worth taking care of protection from contamination of clothing and exposed parts of the body. The point is that during the described operations it is difficult to avoid ink spillage.

- Cotton wool or clean cloth with the help of which it will be possible, if necessary, to quickly remove excess filling material.

- Drill or screwdriver and a thin drill, relevant in situations where there are no special holes in the cartridge for ink injection.

The algorithm of action provides for sequential steps.

- Prepare the workplace, tools and supplies.

- Collect the required amount of ink in the syringe, taking into account the information on the label of the cartridge.

- Remove protective sticker if present.

- Make holes with a thin drill if initially missing.

- Insert the syringe needle into the cartridge compartment to a depth of about 1 cm and fill the reservoir. It is recommended to make several holes through which the liquid will be injected alternately for its even distribution. This rule is more relevant for the black cartridge.

- Remove all excess filling material.

- Seal the holes with the original sticker or tape.

- Insert the refilled cartridge into the printer and start the cleaning cycle. In some situations, it is necessary to reset the settings.

It is important to remember that refueling must be done in a timely manner. Otherwise, during a long idle period, the empty cartridge may become unusable, and it will have to be replaced with a new one.

In addition, during all manipulations, it is required not to allow contact of the nozzles with foreign objects.

Laser

Inkjet devices were replaced by more modern laser printers, and now color models are becoming more affordable for many users. However, when buying cartridges for them, you will also have to fork out (up to 50% of the cost of the entire device). In such situations, again, it makes sense to learn how to refuel them yourself. This will significantly reduce operating costs with minimal time investment.

It should be noted that most ink cartridges for laser printers and MFPs are equipped with chips that control the volume of consumables. By the way, most often, even after refilling, you can find yourself in a situation where the device says that there is no toner, or shows it as empty. To eliminate such messages, if they interfere with the user, you will need to reset the settings or replace the chip itself.

An important point in laser printer maintenance is choosing the right toner. It is highly recommended to purchase refueling supplies from specialized stores. In this case, the model of equipment and accessories should be taken into account. Unfortunately, now, both in land-based retail outlets and on the vastness of the World Wide Web, you can increasingly find low-quality toners. Some users recommend opting for more expensive options, but in practice this rule does not always work.

When replacing toner yourself, you must follow a number of basic rules, which include the following important points:

- highly recommended avoid contact with the working surfaces of the cartridge, the list of which includes a magnetic and rubber shafts, an imaging drum, a squeegee, etc.

- cartridge needs to be held solely for his body.

- the toner is refilled in small portions and with the utmost care.

To refuel a laser peripheral you will need:

- directly the powder itself (toner);

- newspapers or paper towels;

- a new chip if you need to replace it;

- rubber gloves.

It should be remembered that the described process has certain peculiarities. Based on this, it is worth focusing on the most relevant points.

- The result of all manipulations will directly depend on the correct choice of powder.because toners of different brands can differ significantly from each other in their chemical and physical properties.

- It is important at the preparatory stage to determine the workplace and prepare it appropriately... It is recommended to close the table and the floor next to it, otherwise the spilled powder will be more difficult to clean up.

- The next step is to find the toner reservoir. In some cases, you will need to remove the plug from the special hole or do it yourself. As a rule, the necessary tools for this are included in the refueling kits along with the instructions containing the corresponding instructions. After completing all the actions, the burned hole is sealed with foil.

- Some refueling containers are equipped with a so-called nose lid.... This "nose" is inserted into the said opening of the reservoir and greatly simplifies the whole process. In this case, the container itself should be carefully squeezed so that the powder begins to gradually spill out. The functions of the "spout" can be performed by an ordinary funnel.

- As a rule, one filling consumes the entire contents of the container, and therefore it will not be possible to overdo it.

- After filling the tank, it is necessary to close the hole made with foil., the rules for the application of which are described in some detail in the attached instructions. If the plug was removed, then it is placed in place.

- At the final stage, a refilled cartridge is required shake to distribute the powder evenly throughout the container. After that, all that remains is to place it in the printer.

If the device does not "accept" the updated cartridge due to the above-mentioned chip, the latter will have to be replaced.

By the way, in the overwhelming majority of cases it is included in refueling kits. In principle, the entire process described is fairly straightforward. However, special attention should be paid to safe handling of toner.

Operation after refueling

As already noted, the purchase of new cartridges each time will cause significant and unjustified costs. It would be more rational to update the ink supply or toner (depending on the model of the printer or multifunctional device).However, quite often, after self-priming, it is not enough just to install an updated cartridge and restart the equipment - often you need to configure the device or take other actions.

If the printer, MFP give out blank or completely black sheets, as well as error messages appear, then there can be a number of reasons. This means not only clogging of the printheads of the cartridge itself, and the device as a whole due to prolonged downtime of the equipment. In some cases, users have to face with the failure of electronic systems, as well as software failures. Most often, after refueling, the printer simply does not perceive the cartridge as functional... In such cases, adjusting the settings, disabling ink or toner level monitoring can help. Sometimes it may even be relevant reinstalling the corresponding software (drivers).

Experienced users recommend after refueling and before further operation check the conductivity of the nozzles. To do this, it will be enough to apply a napkin to the working surface of the cartridge. If there are clear ink traces on it (black or tricolor), then everything is in order with this element.

Naturally, there are certain nuances of using laser models after filling toner. Most often we are talking about replacing the chip responsible for controlling the level of consumables... Another important point is related to the operation of printers and MFPs manufactured by Brother. Please note that when the cartridge is installed in the device, the gears are connected. At this point, a special counter is reset. Sometimes this does not happen, and the electronics perceives the filled toner cartridge as empty.

It is important to remember that the procedure for resetting the counters may differ from model to model.

In addition to all of the above, during the operation of self-serviced cartridges, attention should be paid the operability of the printer itself or multifunctional device... Also, when messages appear that there is no ink, it will be useful to check print settings and if necessary reset them or make the appropriate adjustments.

Possible problems

Naturally, when restoring the functionality of the cartridges, you may encounter certain difficulties. By the way, this is true for both inkjet and laser peripherals. Minor issues are spilled ink or spilled toner in the workplace. But in situations like this, the main reason for getting dirty is lack of accuracy. Often, after filling with new toner, a printer or MFP smears the sheets during printing or simply does not print well.

According to user reviews, most often they have to face six problems.

- The device “does not see” the updated cartridge and prints out white sheets during the printing process. This is true for chip models, in which a special electronic device protects it from self-refueling. Troubleshooting (unlocking) methods are specific to your model.

- The laser printer prints very faintly... As already noted, many new representatives of the lineup of leading manufacturers are equipped with demo cartridges. When refueling them, certain problems may arise, primarily associated with internal problems. In addition, wear on the drum unit or poor grounding may cause the printer to print dimly. Naturally, do not forget about the quality of the filling material itself.

- A cartridge filled with new toner produces completely black pages... In such situations, we will talk about the exposure of the drum surface, which is characterized by increased sensitivity to sunlight.

- An extraneous background appears. Typically, this effect is due to an incorrect position of the metering blade in relation to the development roller.

- Light stripes along the page. One of the most common causes is powder adhering to the metering blade.

- Repetitive defects in the form of spots, dots and stripes appear on sheets... Most often this occurs due to the hit on the drum, charge roller or development roller of various particles.

After refueling inkjet printers, ink often leaks out of cartridges. In this case, two reasons are possible, namely:

- violation of the tightness of the seams of the cartridge case;

- Leaky opening through which the filling material was poured.

When print quality deteriorates after refilling ink or toner, cleaning the cartridge can often help.

In some cases, this procedure needs to be run several times in a row.

But in any case, self-service and restoration of the operability of a peripheral device is an effective way.

General recommendations

First of all, it is worth paying attention to the nuances of refilling inkjet cartridges. Before filling ink, you should carefully inspect the reservoir... If it contains dried particles of the filling material, they must be removed with wipes and cleaning liquid. After all manipulations, the contact plate must be completely dry.

It is important to remember that empty cartridges must be refilled as soon as they run out of ink. The very replenishment of the volume of consumables should be carried out taking into account certain points.

- All necessary work is carried out on the most even surface in the absence of foreign objects. Working clothes and protective equipment can help protect items and exposed parts of the body from ink. The table itself can be covered with children's disposable diapers.

- It is important to consider that most often the reservoirs do not contain the volume of ink declared by the manufacturer... Based on this, refueling should be 80–90%.

- It is recommended to use syringes with the thinnest possible needles.

- Special attention is required to be paid the condition of the sticker covering the filler openings. In case of damage, use ordinary tape.

The basic rules for refueling laser devices are determined by the properties of the toner. It is a dusty mixture of resins, iron powder, graphite and several other components. It is recommended to follow important rules during its storage and use.

- Toner should be in a tightly closed container and at room temperature.

- Necessary take measures to prevent water from entering the powder (especially hot).

- A toner container is strongly recommended before pouring the mixture into the reservoir. shake well... This helps to get rid of the lumps.

- Important to remember about the toxicity of the powder and, on this basis, do not allow it to come into contact with the eyes and respiratory tract. It is for this reason that you should wear protective goggles and a respirator when handling toner.

- Refilling cartridges is best mixture recommended by the manufacturerdesigned for specific types of devices.

- It is necessary to control the volume of the filled materialas overdose is unacceptable.

Summing up, it will be useful to remind you of the importance of choosing the right filling material. This rule applies to both inkjet printers and MFPs, as well as more modern and advanced laser peripherals. It is important to remember that excessive savings in such cases can cause additional costs for the purchase of new cartridges.

See below for how to refill the Canon Black Inkjet Cartridge.

The comment was sent successfully.