What is a UV printer and how to choose one?

The large format printing market is currently booming. Advanced UV printing technology has revolutionized the development of inkjet printers with devices such as roll-to-roll printers and multifunctional multimedia flatbed devices. It has only been 10 years since the introduction of UV flatbed printers, but they quickly gained popularity around the world. The main reason for this is ease of use and versatility for printing.

What it is?

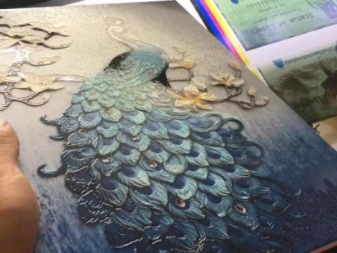

UV printing is a form of digital printing that uses ultraviolet light sources to dry or cure ink. Typically these sources are attached to the print carriage. Since the ink dries very quickly, the droplets have no way of spreading over the substrate. Consequently, the image and text are printed more clearly. Thanks to the instant curing with UV printers, you can create three-dimensional photorealistic graphics on a variety of materials. UV technology allows printing not only paper, but also non-traditional soft and rigid substrates. Most UV printers are compatible with media up to 5 cm thick.

Examples of soft media: reflective film, canvas, leather. Examples of rigid media: glass, wood, aluminum, plexiglass, corrugated board, plastic, resin, drywall. The UV printing process is environmentally friendly as it does not emit harmful volatile organic compounds or waste water.

The resulting printed matter is weather and fade resistant.

Views

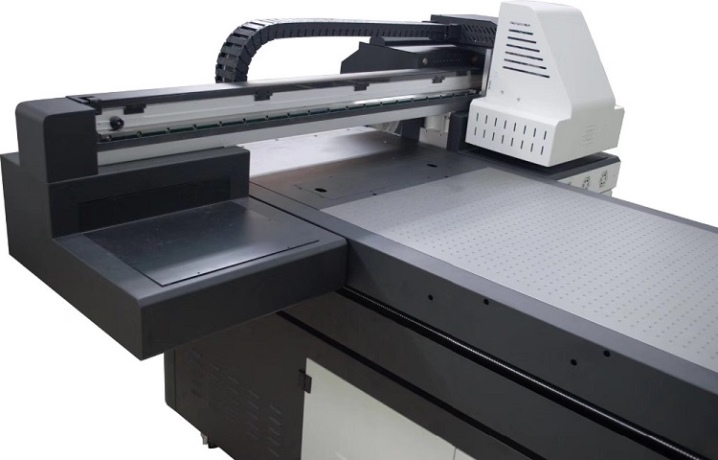

UV printers can be flatbed, roll-to-roll or hybrid. Flatbed models can print any flat media up to 5cm thick, flexible or rigid. The media is placed on a table (or flatbed, hence the name) and is held securely in place by a vacuum during printing, while the print head moves across the surface of the media. This allows for very precise ink distribution and high print quality.

Flatbed printers are compatible with plastic, wood, metal, glass, plastic and of course paper.

Roll-up models, as their name suggests, use flexible roll media. In these models, it is not the print head that moves, but the media. Roll models are mainly used for printing advertising materials: posters, banners.

Hybrid models are essentially roll-to-roll printers, which are additionally equipped with a removable table and a belt drive system for feeding hard media into the printing area. This design was developed by manufacturers to expand the use of roll-to-roll printers without significantly increasing their cost.

How to choose?

The main question that must be answered when choosing is which type to give preference to, because each type has its pros and cons. Let's consider them. The advantages of hybrid models are mainly associated with the ability to use two types of media simultaneously.

They are not without drawbacks.

- Poor drive belt alignment can result in skewed images, resulting in irreparable reprint losses.

- Drive belts can leave marks on the media and must be cleaned frequently.

- Only lightweight media that has at least one 90 degree angle can be used for printing. Print quality is poor on heavy media, or on uneven or irregularly shaped media.

- Although the printer itself may be small, it can take up quite a bit of space to accommodate it. This is due to the need to have special devices for feeding the media at the entrance and receiving at the exit.

- Switching between roll and rigid media requires a physical system reconfiguration.

Now let's take a look at the advantages of tablet models.

- High print quality.

- No restrictions on the shape and state of the surface of the carriers. The only condition is that they must be fairly flat.

- Full printing capability, eliminating time-consuming trimming.

- The ability to place several small media on one table while printing.

- High-quality printing of large images on multiple media. Since there is no possibility of skewing the media, there are no gaps between the individual parts when assembling the image.

The disadvantage of tablet models is that their cost can be higher than that of hybrid models.

Other points to pay attention to:

- the cost of consumables (ink, UV lamps);

- the size of the required working space;

- the cost of spare parts and annual maintenance;

- number of operators for service.

Popular models

Currently, China is the main manufacturer of UV printers (over 95% of world production). The quality of printers from China is different. Large manufacturers have more experience in developing and mastering new technologies, so their models are of good quality.

ColorSpan DisplayMaker 72UVR

This 180 cm model allows you to use both roll and rigid media up to 0.6 cm thick.For hard media, removable tables are installed at the front and back of the printer, which can accommodate sheets up to 150 cm long. SolaChrome UV ink with UV curing. Dual high intensity UV lamps are installed on each side of the print head for instant ink cure. There are a total of 16 Hitachi printheads with a resolution of 600 dpi. Print speed ranges from 9.3 to 37.2 sq. m / hour depending on the required quality.

Other features:

- removable pinch roller system for easy insertion of hard media;

- system for automatic check of media skew and color calibration;

- linearization with a built-in spectrophotometer that feeds color and density data to an external color management program.

In general, the DisplayMaker 72UVR is designed for outdoor advertising, exhibition displays, banners and floor graphics.

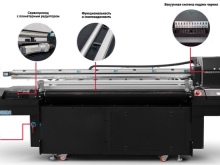

Freecolor 6090 UV Flatbed Printer

Multifunctional model that can be used to create souvenirs, digital signage on monitors, name badges, photo ID cards, plaques. Both rigid and flexible materials can be used as a carrier: PVC, glass, plastic, organic materials, leather, rubber, paper, metal, wood, porcelain. The model is equipped with UV LEDs and a water cooling system. There are also many built-in applications.

The Multipal Colors application allows you to print with both white and color inks, which significantly speeds up the production process. RIP-printing compatible with JPEG, PDF, EPS formats, and 3D volumetric printing on any substrate from clear glass or acrylic to dark ceramic.

The working size of the press is 600x900 mm, the maximum thickness of the used media is 80 mm. If you need A3 printing, you can recommend a model from the same series - Freecolor UV4060. It differs only in the working print size - 32x56 cm.A feature of this model is the presence of refillable cartridges. Refills are done using a continuous ink supply system, which makes it easy to add ink to the cartridge as needed. This significantly increases operational efficiency by reducing downtime.

The model is protected from the effects of atmospheric factors (water, sunlight), therefore, it is also suitable for outdoor use.

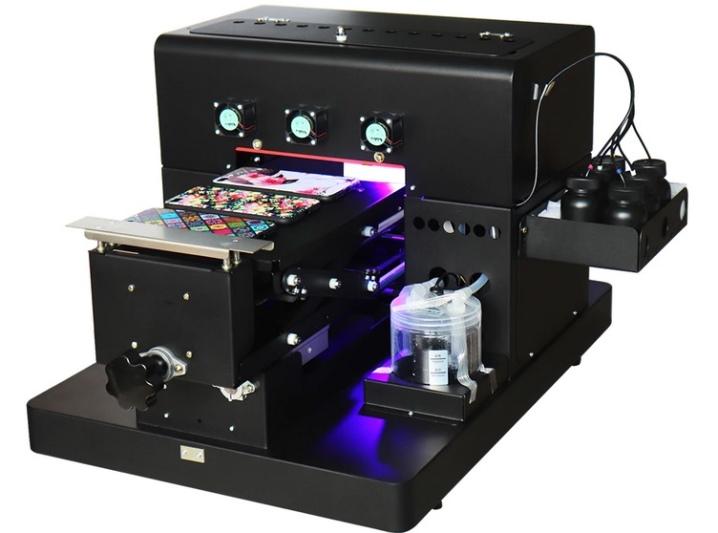

A4 Small UV Printer

This is a small desktop mini-printer for printing on various materials: acrylic, PVC, metal, wood, plexiglass, crystal, copper, tiles, leather. Its dimensions are only 650x470x430 mm, and its weight is 26 kg. All surfaces can be printed directly without prior priming. It takes 163 seconds to print an image on A4 sheet. There is a continuous ink supply system and water cooling.

Typical applications include printing on phone cases, personalized gifts, photographic products, promotional items, pens, lighters and flash drives, souvenirs, awards, small signs, decorative tiles, and more. Suitable for direct printing on all surfaces, including 3D objects up to 15 cm thick. Printing on dark or transparent substrates is also possible using white ink.

Due to its compact size, the model is suitable for an office or home business.

Repair and service

Some services do not require special knowledge and can be performed independently. For example, replacing a cartridge or refilling paper. To do this, you just need to read the instruction manual. You can independently clean the cartridge from lint particles (using compressed air).

Sometimes the problem is with the software or the network and not with the printer itself. It is also possible to diagnose and fix these problems yourself. However, you should not try to repair the printer with your own hands if something constantly gets stuck in it, there are unpleasant sounds or smells, and also when some parts need to be replaced. In this case, it is better to seek professional help.

In the next video, you will find a review of the Dilli Neo Sun FB2513 UV printer.

The comment was sent successfully.