What is printer flush liquid and how do I use it?

Pigment inks are now used for many printers. In their basic properties, they are similar to the permanent paint used in construction. To rinse such substances from printing equipment, you will need a special flushing fluid. You should know what it is, and what types of such compositions are.

What is it for?

Printer flushing fluid is used in several applications. Most often it is used for thorough and timely cleaning of the cartridge, which should be periodically refilled. If cleaning is not carried out, then a chemical reaction between inks from different manufacturers is possible. Subsequently, harmful sediments may fall out, which will negatively affect the operation of the equipment.

Also, flushing fluid is often used when blocking printheads. In this case, such a composition is taken at a stage when the usual cleaning could not bring the desired result. Sometimes the composition is taken to clean various other parts of the printer after splashing too persistent pigment substances.

It is not uncommon for printers to break down precisely because many users do not use special flushes to get rid of dried ink.

Indeed, as a result, this leads to rapid clogging of the nozzles of the printing parts. To avoid such troubles, it is best to regularly clean the devices. Flushing fluids can either be purchased at a specialty store or prepared by yourself at home.

Printer flushing solutions can also be used as a special preservative. In terms of their composition, they are quite close to paints, therefore they do not contribute to the rapid precipitation of the sediment. But this phenomenon is inevitable, because all coloring elements have their own shelf life (as a rule, it is only 1 year). If you dilute the cleanser, then the process of formation of pigment deposits will be significantly accelerated.

Views

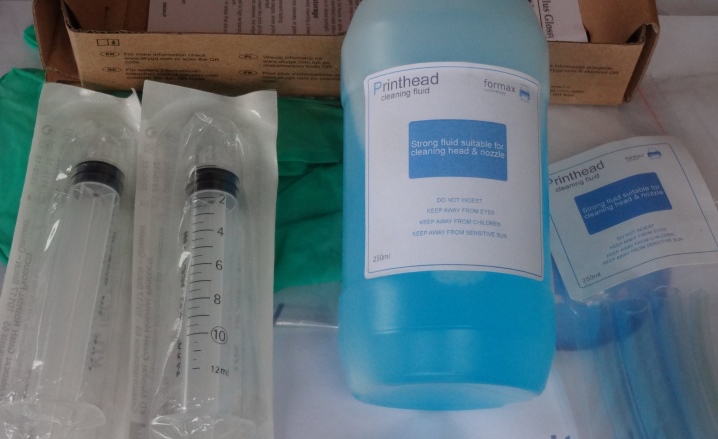

Currently, there are a large number of different fluids for flushing printheads. Certain types of such substances should only be used with certain manufacturers' printing equipment.

Liquids can be acidic, alkaline or neutral, depending on their composition. The last option is the most versatile and practical. It can be taken for almost any office equipment. Distilled water is the basis of neutral liquids. And also a little alcohol and glycerin are included in the composition.

We recommend purchasing alkaline flushing fluids for cleaning inkjet printers from Canon or Epson. Like the previous version, their composition includes distilled water, glycerin and alcohol. And also includes ammonia. Acidic substances are best used for HP color fixtures. The products consist of distilled water, the essence of acetic acid and alcohol.

In specialized stores today you can see flushing fluids from different manufacturers. Several designs are most popular with consumers.

- Inktec. Used to clean Canon or Epson inkjet printers. As a rule, it is taken in cases when characters of certain colors begin to print poorly on paper, or when the technique has not been working for a long time.The shelf life for such a substance is 2 years.

- Flushing OCP. It is sold in small bottles of 100 g. Shelf life is also 2 years. This option will do an excellent job of cleaning the printheads of the printer.

How to do it yourself?

If you do not want to purchase professional cleaning fluids from a specialty store, then you can prepare them yourself at home. There are several ways to make such substances.

The finished flushing liquid can be replaced with ordinary distilled water. But at the same time, before washing, it must be heated to a temperature of 50 or 60 °. This option is most commonly used to clean inkjet printing equipment. Cleaning with distilled water will be effective if the printer has not been used for more than 2-3 months. Otherwise, the procedure simply will not bring the desired result.

And also at home, you can prepare standard custom formulations that are sold in stores, but you should carefully select the proportions of the components. So, when creating a neutral sample, you need to mix:

- 80% distilled water;

- 10% glycerin;

- 10% medical alcohol.

If you decide to make an alkaline liquid, then it is better to take:

- 70% water;

- 10% glycerin and medical alcohol;

- 10% aqueous solution with ammonia.

For an acid mixture, you will need 80% water and 10% each of medical alcohol and acetic acid.

Many people make a liquid based on window and mirror cleaner. In this case, you need to carefully read the composition of such a cleaning agent in advance.

It must include elements such as isopropyl alcohol and sodium sulfoethoxylate. These important components contribute to the rapid softening of dried color pigments.

Pour 9 parts distilled water to 1 part cleaning agent into a separate, clean container. In order not to be mistaken, you can use a marked syringe. Then the contents of the container are slightly stirred and they try to clean individual parts of the printing device with it. If the desired result is not, then you can add a little more funds. But in any case, its total share should not be more than 50% of the entire solution.

If before the procedure you want to check the homemade flushing composition, then you need to mix in a separate container a few drops of ink from the printer with the resulting liquid and leave for 2-3 hours. If the pigment then becomes too viscous, then this cleaning agent should not be used, it can harm the equipment.

How to use?

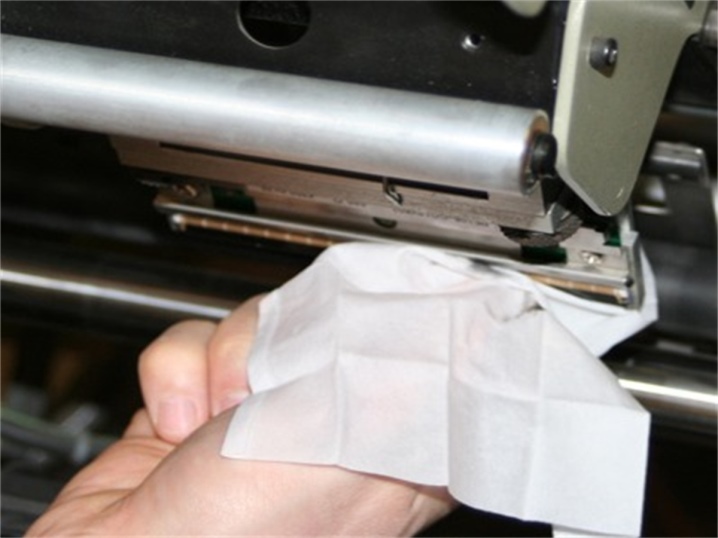

If you want to clean the printer with such a liquid, there are some rules you need to follow. Remember that first, the technique should be wiped with plain clean water without using a professional substance.

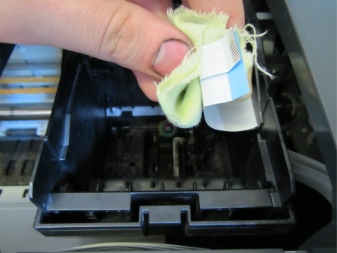

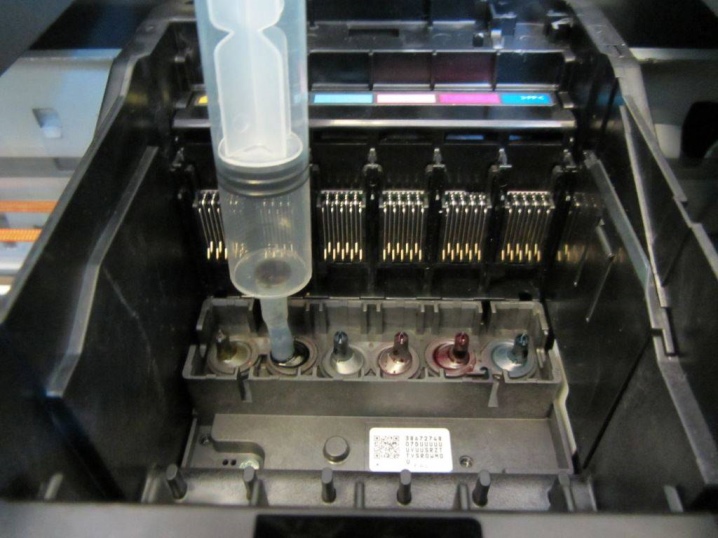

If you are using a custom-made composition, then you better first lower the print head of the equipment into a container of warm water for a few minutes. Its temperature should be around 40 or 50 °. Then immerse the structure in the cleaning solution for 10 minutes. Draw out the coloring pigments with a syringe. At the end, all leftovers are removed with a napkin or rag.

If you are using a professional flush from a store, then you should carefully read the instructions for use.

Most often, the printed elements are immediately placed in the cleaning liquid 1 cm. The structure remains in this form for 2–4 minutes.

After that, the elements are transferred to a special ultrasonic bath for printers. It must first be filled with distilled water. Parts remain in this container for a few seconds. Then the ink is removed with a syringe, the remains are removed with a napkin, all parts are returned after cleaning to their place.At the end, for verification, it is recommended to perform regular cleaning and printing of the pattern; if necessary, the procedure can be repeated several times.

Recommendations

There are some important tips to follow when cleaning your printer's printed elements.

- Remember to flush equipment before every refueling. This will avoid mixing different coloring pigments, which can enter into chemical reactions with each other with unknown consequences.

- If you use a wash to remove one color, and the procedure results in a different color, then this means that the head is out of order. In this case, a complete replacement of the element will be required.

- Depending on the type of ink you refill the equipment (pigments or water-based paints), you need to select the appropriate cleaning agent or you can use a universal neutral composition.

- It is better to start each cleaning with a preliminary rinse with regular distilled water. This procedure will make it possible to maximize the life of the printer nozzles.

How to make flushing liquid for printers, see below.

The comment was sent successfully.