All about Bosch dishwasher pumps

Any dishwasher malfunction is the result of specific causes. If the machine has stopped draining water, look for the source of the breakdown in the evacuation (drain) pump. Dishwashing problems? This means that you need to check the circulation (recirculation) pump. Replacing the dishwasher pump is one of those types of repairs that are carried out on their own. The main thing is aspiration and step-by-step guidance.

Peculiarities

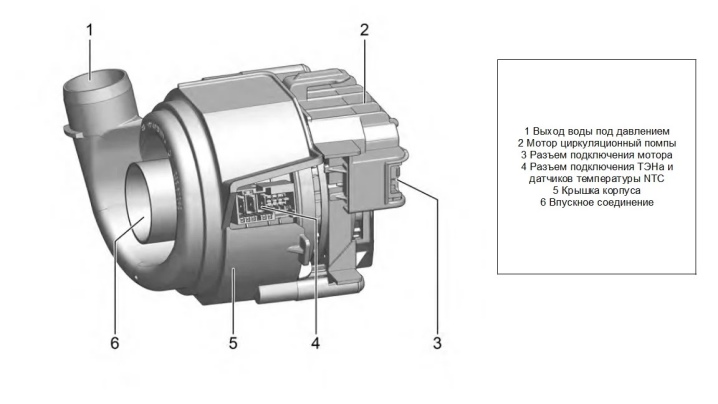

The circulation pump is designed to fill the system with water. It functions incessantly, pumping and supplying water to the rocker arms (sprinklers), from where it is ejected under strong pressure. The machine opens the dispenser (dispenser) of detergents, and the leftovers of food are washed into the pan, from where they enter the filter. The used water is purified again and sent to the nozzles. For this reason, the pump is also called a recirculation pump.

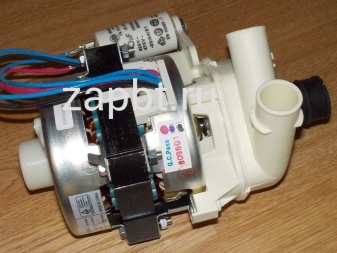

The bilge pump drains the used water out of the working chamber. After the end of the cycle, the control unit sends it a signal to pump out.

Additional elements

A serious problem can be the breakdown of the components of the circulation and drain pumps of the Bosch dishwasher.

A common cause of failure of the recirculation unit is leakage. The liquid medium penetrates into the graphite bushings, flushes out the lubricant, which leads to their wear. The most vulnerable area of the drain pump is the impeller. Threads are often twisted around it, hair, blocking the operation of the device, in this regard, it is important to perform regular cleaning. In more modern models of Bosch dishwashers, heating elements often fail.

How to check?

With little knowledge of technology, it is quite possible to independently determine for what reason the dishwasher is uncharacteristically noisy or does not work at all. If the water does not circulate in the unit, the fine and coarse filters are not clogged, and the nozzles on the sprinklers are clean, then this is a sign that the time has come to change the circulation motor - there can be no other versions.

Attention! The circulating motor is not repairable, it is subject to replacement.

If the water in the Bosch PMM is not heated, then the replacement of the recirculation pump is also required, since elements of instant action work there to heat the water - they cannot be disassembled.

The most famous reason for the failure of the drain pump, not only on Bosch machines, but also on other products of a similar type, is the contamination of the drain filter together with the pump with foreign objects. The filter is very easy to clean, and it is ready for use again, but the situation with the pump is often much worse, if it does not function, it must be changed. To dismantle, you will need to disassemble, in fact, the entire machine. If you doubt your own abilities, then it is advisable to invite a specialist.

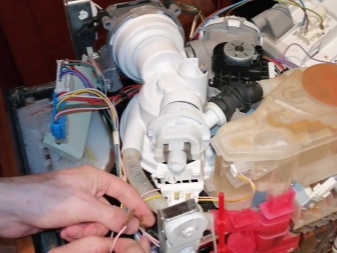

How to remove?

This requires a flat and Phillips screwdriver. But, to be sure, you should prepare pliers, an ammeter and an awl:

-

pliers are required to tighten the fasteners that hold the dishwasher pump;

-

screwdrivers are needed to unscrew the fasteners;

-

an awl will be needed in order to hook up the panels for ease of removal;

-

an ampere-voltmeter is necessary to measure the resistance of electrical parts.

The process of removing the drain (drainage) pump PMM is performed in several steps.

-

The unit shuts down, de-energizes, the water is shut off. Before working with PMM, absolute disconnection from communications is mandatory. The renovation work will be safe.

-

Remove dishes, wire rack and filter devices from the machine. They close the access to the key work site.

-

Remove water from the pan. If the unit does not have access to the filter element, the water should be collected with a sponge or cloth.

-

Remove the cover, rocker tube, drain grate and screw. All elements are fixed with self-tapping screws or inserted into the grooves of the device. Through them, the rotation of water and its discharge are formed in the PMM.

-

A plastic or metal panel is located underneath the dismantled components. It can also be fastened with latches or bolts. It must be removed.

-

A two-layer heat insulator made of foam rubber and felt is placed under the panel. It is also advisable to remove them for convenience.

-

The body of the unit can be tilted back, wipe the surfaces. For more convenient access to the pump, the front self-tapping screws of the pallet are also unscrewed.

-

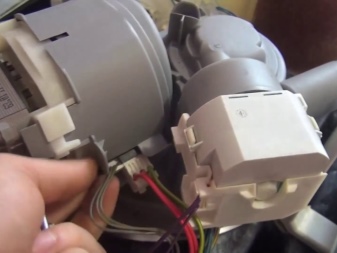

The pump is located in a special seat. A cord, a tube and a water regulator are attached to it. The parts are carefully detached.

-

After disconnecting the cord and tubing, the pump can be removed. The structure of the product is very similar to the pumps of washing machines.

-

A new spare part is mounted in the old place. The connected parts are installed in the same order. In order not to confuse their location, you can shoot the pump in advance with a photo or video.

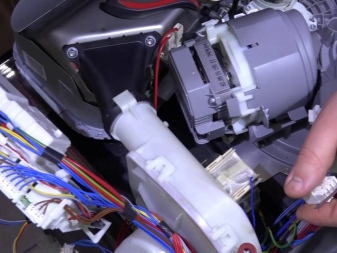

Removing the recirculation pump is easy. Stages:

-

open the loading door of the machine, and remove all unnecessary from the chamber;

-

carefully remove the sprinkler from the place of fixation;

-

remove the coarse filter mesh;

-

unscrew the fasteners;

-

dismantle side panels, plastic fasteners;

-

we remove the thermal insulation so as not to interfere, put it aside;

-

for convenience, carefully set the machine upside down;

-

disconnect the inlet hose and the pallet with elements from the body;

-

disconnect the electrical wiring and drain hose;

-

carefully dismantle the door fasteners - springs, disconnect the inlet and drain hoses;

-

carefully dismantle the pallet so as not to damage the float;

-

the pump block has opened.

Now all that remains is to remove the recirculation pump and install a new one.

The comment was sent successfully.