Shell garage: pros and cons, standard sizes

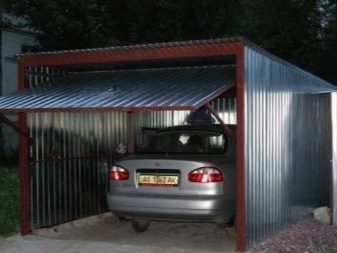

Along with durable garages made of bricks or sheets of metal, so-called shells are also popular. In fact, they are a temporary option for a car shelter, so they can be moved or dismantled.

Peculiarities

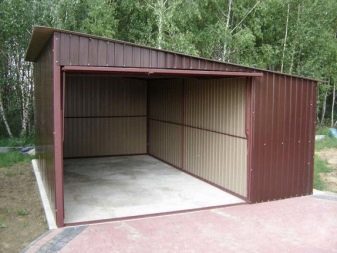

The garage got its name from the fact that it really resembles a neat metal shell in shape. It gained popularity due to its low cost and compact size. Such a structure is easy to install directly on your site next to the house. Even the servants of the law cannot prohibit this, since the shell cannot be classified as a full-fledged garage - only as a car awning.

If the owners decide to build it with their own hands, then the savings in the family budget will be significant.

And compared to building a full-fledged garage, it turns out to be very cheap.

By the way, despite the compact size, this type of structure accommodates not only a car, but also the tools needed to repair it, garden tools or light vehicles such as a scooter or stroller.

The sturdy garage shell protects the car well from potential threats. A metal awning hides the car from rain, snow and other weather surprises.

But in addition to the advantages listed above, there are a number of disadvantages.

- No matter how convenient a shell garage is, it is still significantly smaller than a classic brick building. The inside of the building is cramped and uncomfortable. In some cases, it is impossible even to open the car door.

- The shell garage looks unpresentable. Many do not want to install it for this very reason, believing that it will ruin the appearance of the site. In addition, over time, the surface becomes rusty or prone to corrosion.

Specifications

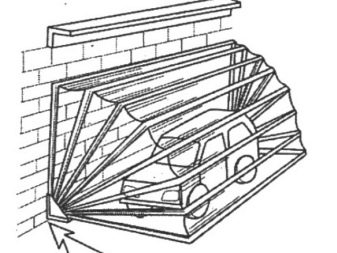

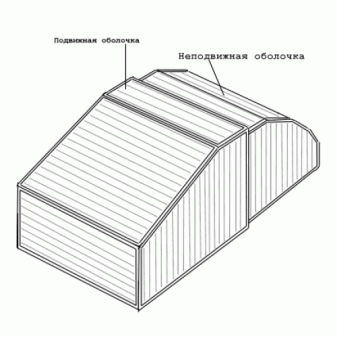

The classic shell garage is used for storing a passenger car. As a rule, it consists of two steel or reinforced concrete sashes. One of them is firmly fixed and stands on the floor. But the second one, like a gate, opens. It rises, turns and lies on top of the base of the gate.

It turns out that when you open it, half of the car is immediately on the street.

Materials used

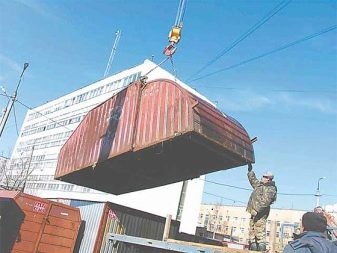

For the manufacture of the garage, durable metal is used. Thick sheets, as a rule, weigh a lot. Usually their weight is within a ton. Therefore, it can be difficult to work with them without the use of special equipment.

It should also be noted that the shell is almost impossible to lift and move without a crane.

Security

A two-leaf design is considered vulnerable by many. Indeed, snow or raindrops can easily fall into the gap between them. In order to further protect the car, experts recommend using various seals. Alternatively, tarpaulins are also bought. However, this option is also risky, since the metal can become rusty under the tarpaulin.

In addition to weather conditions, the car must also be protected from vandals. The lock is installed at the junction of two leaves. Shells tend to be easy prey to would-be robbers. That's why it is recommended to choose the most reliable locking schemes.

Standard sizes

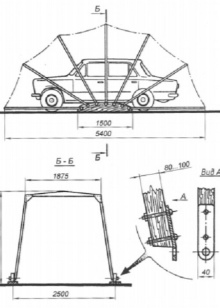

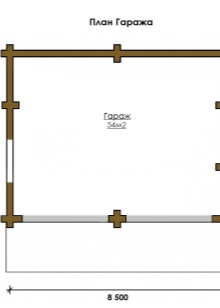

As in the case of a standard garage, the parameters of the shell depend on what kind of car they plan to keep in it.The usual parameters are two and a half meters in height, three meters wide, and six meters long. This, as a rule, is enough for the motorist to safely park the car without touching the walls.

For the manufacture of such a structure, solid sheets of a metal profile are used. It weighs a lot, so you have to mess around with cutting and installing it for a long time.

Views

There are several main types of such garages, each of which has its own advantages and disadvantages.

By the nature of the location, structures are divided into attached and built-in ones. The second type is bad in that it can only be built in the process of building a house from scratch. It is installed on the basement floor and, if desired, can even have an entrance to the house. Thus, in winter, you can get into your garage without even walking in the cold. If a protective building for the car was needed after the house was rebuilt, then you should choose another option. Namely - an attached garage, which can be located next to the housing, even be attached to it using a convenient corridor.

Separately, a collapsible metal version of the shell is distinguished. They can be placed anywhere, even in the middle of the yard. Compact buildings of this type are quietly located even in the city, and not only in summer cottages.

The last classification is the division of seashells depending on the material from which they are made. They can be block or metal. The mechanisms that open the gate are also different. They can be either mechanical or automatic.

As the name implies, in the first case, the sash must be raised and lowered manually, and in the second, everything is done automatically using a special mechanism.

How to assemble?

Any garage structure of this type is built in several stages.

Location selection

Before building, you need to determine the ideal place for the construction of the shell. For the garage, you need to choose a flat surface, ideally filled with concrete.

It is also worth deciding in which direction the sash should open. Most often, they try to place the shells in such a way that the driveway is short and convenient. For this reason, they are located closer to the gate.

Find tools

The next step is choosing the right tools. The task is not difficult, but someone who has never done anything like this will still need to tinker both in the process of work and with the choice of materials and improvised means.

The base of the garage is made of metal profiles. Therefore, you will need large sheets and a welding machine to connect them. They are cut using a grinder and a set of discs. Care must also be taken to have different measuring instruments at hand. Their list is quite short: caliper, tape measure, hardware.

Manufacturing of blanks

When all the components are selected, you can start building a shelter for the car. As a rule, it takes about five to seven days to build a shell. Especially if the person has never done anything like this.

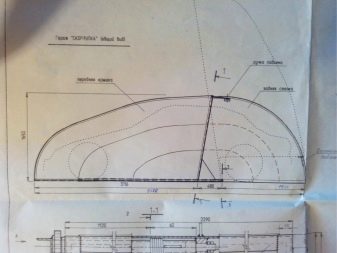

The first stage of construction is the preparation of units. Individual sections can be of different sizes. The parameters are matched to the car. For a large car, you need a large shelter.

It is also worth considering the moment that the movable sash should be larger, since it should cover the base, freeing up space for the passage.

For a fixed section, you will need not only a wide metal sheet, but also two racks cut from a steel corner. They are placed at the edges, and at the top they are connected using a special metal crossbar, which should be as wide as the future garage. All these parts are welded together, resulting in a structure that vaguely resembles a football goal. Just like this gate, the future support needs additional timber props.

A metal arch can also be made by hand. It is impossible to bend a steel corner without the use of additional tools, so welding will be needed, with which the base can be divided into parts about thirty centimeters wide.

The second part of the shelter is made according to the same principle, however, it needs to be expanded a little. The increase in this part is important, because without this it will not be able to open completely.

Assembly

After all the blanks are made, you can proceed to the assembly stage. It is at this moment that the connection of the two parts of the shell occurs. Both workpieces must be placed on a flat surface and determine exactly where the hinge will be fixed. Simple garage hinges can also be used instead.

The fixed part of the workpiece is fixed at this stage. This can be done using anchor bolts. Then the second part is attached. When the frame is ready, you can sheathe both sections with metal strips. They also need to be prepared in advance, having calculated what height and width are needed.

At the junction of two separate sections, it is imperative to weld the hinges for the lock or install another protective structure. After completing the preliminary work, you can proceed to work with surfaces. First thing you will need an anti-corrosion agent, which will protect the shell from external damage. The next layer is paint... As a rule, gray is chosen because it is the most versatile and least easily soiled.

In some cases, motorists, on the contrary, try to highlight the garage by making it brighter. To do this, it is not necessary to completely paint the entire metal base. Sometimes it is enough just to apply a few bright stripes at the joint. These pencil cases look more interesting, and painting them will not greatly increase spending.

Finding an alternative

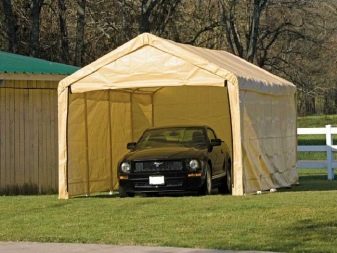

Shells made of durable metal profiles have many advantages. But due to the heavy weight, problems with movement and other nuances, many are still looking for other, more convenient options. One of these can be called a garage of the same type, but made of awning fabric.

The design of the required height will also provide reliable protection from rain and scorching sun. Like simple high-quality awnings, it does not let in either wind or water. To protect the car you can use either tarpaulin or polyester fabric impregnated with various protective compounds... This version of the shell is perfect for temporary housing, for example, for a summer cottage or a suburban area where the family does not live so long.

Advice

The shells are very comfortable and compact. To make them even better, you can use additional tips.

So, for example, car enthusiasts who spend a lot of time repairing or tuning a car will like the idea of insulating the garage at least a little. To do this, you need to sheathe it with panels from the inside. The classic heating option is hardly suitable here.

It is not worth saving on the insulation of the structure in the same way as on its protection. The anti-corrosion coating chosen to protect the metal must be of high quality in order for the building to last longer. If the shell is placed in a place with a cold or rainy climate, then the protective layer will need to be renewed over time. Not only the appearance of the garage depends on this, but also the level of security of the car.

And, finally, before installing the "pencil case", especially in the city, it is worth checking once again how legal it is. Laws change over time. To be sure that the new building will not be forced to demolish or move to another place, you need to clarify what rules are in force now.

The following video provides an overview of the shell carport.

The comment was sent successfully.