Metal garage: types of structures and installation features

Owners of any vehicle need to protect it from external climatic factors or theft. One solution to this problem is to use a garage. These designs allow not only to limit the impact on the car, but also to comfortably carry out repair operations. Today, metal garages are gaining special popularity, as they are compact and fast in installation.

Peculiarities

A metal garage is a metal structure that can withstand external physical and climatic stress.

These structures are made using several types of materials:

- Iron sheets. They are used to cover the frame and create a solid system. The best option would be thick steel canvases that can withstand high physical activity. But today you can find garages that are sheathed with thick profile sheets. Such a structure is not always reliable, although the bearing capacity of the garage does not become worse from this.

- Metallic profile. It is made in most cases from corners, shaped and round pipes. Together they form a monolithic system that can withstand various loads.

The installation of a metal garage can be carried out both on a specially prepared foundation and on leveled ground. Metal products are practically no different from brick structures in terms of strength.

Advantages and disadvantages

Many car owners prefer metal garages.

This is due to several advantages of these metal structures:

- Resistant to fire. The metal does not burn at all and does not support combustion, which makes it completely safe in the event of fires.

- High strength. Structures made of thick and high-quality metal are difficult to crack. But these indicators are slightly worse than those of monolithic brick structures.

- Relatively low cost. The price of a garage depends only on the method of its manufacture and the quality of the metal. In most cases, these indicators are much lower than those of classic monolithic buildings made of bricks or aerated blocks.

- A metal structure is not legally considered a monolithic structure. Therefore, these structures can be easily erected without specialized documentation.

- Speed and ease of installation. It is possible to design such a building even without a certain amount of experience. There are several types of prefabricated metal garages on the market today. They only need to be properly assembled by connecting all the elements according to the manufacturer's instructions.

- Relatively light weight. If necessary, a building made of metal structures can be moved, which is impossible for monolithic structures.

But metal garages are not universal designs.

Such systems have several significant disadvantages:

- The minimum level of thermal insulation. Metal does not retain heat well: it is rather difficult to work inside them in winter. Therefore, many experts recommend to additionally insulate the walls with various materials. Uninsulated garages quickly cool and heat up, which also leads to the formation of a large amount of condensation. He, in turn, has a bad effect on the metal of the structure and the car.

- Inability to install electricity. This is due to safety precautions.Theoretically, it is possible to supply current inside, but if it is produced only by its own generators.

- Low level of fire safety. The metal itself does not burn, but it heats up very quickly, and the presence of cracks can lead to the penetration of fire from the outside into the building, with subsequent damage to the car and all other property.

- The minimum level of protection. This refers to structures that are installed on a dirt or asphalt surface and are not attached to it in any way. Some craftsmen can simply raise the structure with a jack by prying one of the walls. Metal bases are also well destroyed by a grinder and special circles. Therefore, in terms of safety, a monolithic structure is much better.

Constructions

The construction of any metal structures requires preliminary calculations of all technical parameters. It is not always possible to do this without certain skills. But simple modifications can be calculated by yourself. Depending on the structure of the building, metal garages can be divided into several subspecies:

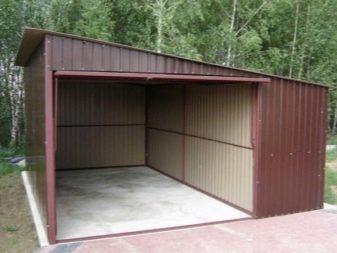

- Factory buildings. Garages of this kind are in most cases collapsible and portable. To assemble such a product, you will need to stock up on only a few types of wrenches, a hammer, factory drawings and other auxiliary tools. Among the advantages are practicality and durability. But the cost of such a structure is much higher than that of an independent construction. Garages are often no larger than a one-story building.

One of the varieties of these garages are used structures that can be purchased at various trading platforms.

Prices for them are already much lower than for new modifications, and it is also possible to independently export from a specific place.

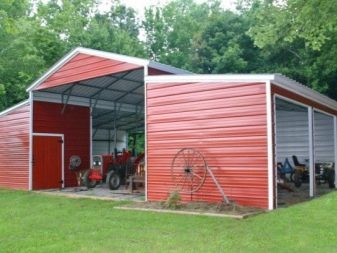

- Self-built garages. These buildings are distinguished by their unique technical properties and dimensions. Some owners make two-story structures that allow them to be used as additional storage space. Many modifications are monolithic, as they are reliably fixed to the concrete foundation. Please note that here welding is already used for the connection. This approach allows you to get a durable system that can withstand loads for a long time. But self-assembly of a garage already requires specialized skills in working with different tools. Therefore, it should be carried out only by specialists who are able to correctly calculate all the parameters.

Preparatory work

The construction of any structure requires preliminary planning. This will eliminate many unforeseen situations and create a strong and durable building. Installation of a metal garage involves the following preparatory operations:

- Choosing a place for construction. It is desirable that the garage is located in a place convenient for car movement. If you have a private plot, then you can install it directly near the road. In another case, it is desirable to ensure an optimal vehicle arrival. It is necessary to install metal garages remotely from a residential building and only on elevations. If the structure is constantly flooded with melt or groundwater, then it will quickly rust and become unusable.

- Preparation of the base. Before starting work, it is advisable to remove the top layer of black soil, as well as level the soil. This will simplify all other installation work.

- Design. There is no one-size-fits-all recommendation here. The dimensions of the garage should be such that your vehicle fits easily inside. If you plan to carry out repairs in this building or store spare parts, then the parameters need to be increased taking into account these requirements.

- Purchase of building materials. To build a garage, you will need a lot of thick metal sheets, shaped pipes, as well as a welding machine, bolts, screws and other fasteners. If you plan to make a warm building, then you need to take care of purchasing a certain amount of heat insulator (mineral wool and others).

Mounting

Building iron garages is a relatively simple operation. But it will not always work out to do it only with your own hands. It is better to carry out all work with several assistants who will not only help to bring materials, but also hold the structure during assembly.

The installation of garages begins with the arrangement of the foundation. It is undesirable to install the structure only on compacted soil, as it will contribute to the development of corrosion processes.

For such a structure, several types of bases can be used:

- Monolithic foundation. A structure of this type perfectly withstands all kinds of loads. But for such light buildings it is not effective to use it, unless the foundation has already been previously built for something.

- Floating foundation. A good and inexpensive option. For the construction of such a foundation, several reinforced concrete slabs should be laid on pre-rammed and leveled soil. The installation of these elements is carried out by a crane, which in turn increases financial costs.

- Strip foundation. The best option for metal garages. It's relatively easy to build. Initially, a canal is dug around the entire perimeter of the future building. The depth of the trench should not exceed 50-80 cm, as this is quite enough to withstand the small weight of the garage. After that, sand and gravel are poured into the bottom of the ditch, then everything is rammed. To improve strength, you can lay a granite stone here, and then fill it with a liquid cement mortar. A formwork is mounted on top, which is already filled with concrete. The height of the support is selected individually depending on the needs of the owner and the characteristics of the soil. But it is not recommended to make formwork that is too high, as this will increase the amount of materials for leveling the floor.

The algorithm for the construction of a metal structure consists of the following sequential steps:

- Frame construction. Outwardly, it resembles a parallelepiped, the walls of which are reinforced with additional posts. From the side where the gate will be located, a kind of internal frame is erected for these structures. Pipes are connected to each other by welding. If you do not weld the profile, but fasten it together with bolts, then over time there will be small fluctuations and the structure will not be so strong.

It is advisable to additionally strengthen the profiles with stretch marks, metal corners and other similar elements.

The roof can be one- or two-pitched. If the second option is preferred, then it is necessary to ensure the possibility of attaching the metal structures to the main frame. The construction of this system involves the manufacture of frames in the form of triangles, and then attaching them to the main supports. The lags are connected to each other using metal jumpers.

- Sheathing. This step is relatively straightforward. Start the wall cladding from one of the corners. To do this, a metal sheet is welded or screwed to the frame. The second option is used together with profiled sheets, which can be selected for any building size. When sheathing, it is important to completely eliminate the presence of any cracks. Therefore, you need to monitor the density of the joints, where they are formed. If a profiled sheet is used, then it is overlaid on top of each other. In the case of welding, the joints are well welded or closed with additional metal plates.

- Gate installation. The pre-prepared metal frame is adjusted to the dimensions of the opening. Hinges are welded to both elements, on which the sashes are then suspended.It is important that the door completely covers the opening and prevents air from entering the garage.

- Warming. This step is optional, but it is almost always done. For this, sheets of mineral wool are used, which are placed between the profile pipes from the inside. At the same time, it is important to cover them with plastic wrap so that moisture does not penetrate into the structure of the material. After laying the cotton wool, it is sewn up with metal sheets or other finishing materials.

Tips & Tricks

Installation of metal garages is a long and laborious operation.

To get a high-quality and durable design, you should be guided by several rules:

- Use only high quality metal. It is undesirable to use elements damaged by corrosion, as this will lead to a very quick repair of the product.

- Be sure to cover the metal with protective primers and paint. If this is not done, rust will form on the surface very quickly.

- When insulating a garage, electrical wiring should not be placed inside the insulation.

- To simplify repairs, you can build a survey pit inside the building. It is advisable to plan its presence at the initial stages.

- Install several locks on the gate to make it more difficult to break into the structure.

Metal garages are versatile and practical structures that, with proper construction, can turn into a full-fledged place for storing and repairing a car.

For information on how to make a metal garage with your own hands, see the next video.

The comment was sent successfully.