All about garages made of expanded clay concrete blocks

Expanded clay concrete in recent years has become a very common material for the construction of lightweight, but sufficiently strong structures. Even rather large buildings are built from it, and even more so it is suitable for building a garage. Before starting construction work, it is worth understanding the technology and sequence of actions.

Advantages and disadvantages

Garages made of expanded clay concrete blocks are popular these days due to a number of their own advantages:

-

environmental friendliness - unlike related slag concrete and many other similar materials, expanded clay concrete blocks do not emit any toxins even when heated;

-

profitability - expanded clay concrete will cost the site owner much cheaper than most alternative materials;

-

construction speed - taking into account the size of each individual block, it is easy to assume that the installation is several times faster;

-

insulating properties - the porous building material does not allow heat, moisture, or extraneous sounds to pass through, creating a comfortable atmosphere inside the room;

-

environmental resistance - expanded clay concrete does not rot and does not rust, it is also uninteresting to pests;

-

light weight - due to their low density, light blocks are convenient to transport, their large dimensions also do not interfere with work without the help of construction equipment.

Of the more or less serious disadvantages of expanded clay concrete, only its comparative fragility can be distinguished, but let's be objective - the building will last for decades, and this period will be enough for the life of the owner.

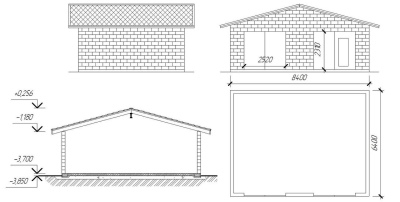

Design

The garage should not be perceived purely as a box for a car - in modern creative projects, the building is additionally equipped with a comfortable attic. Besides, it is worth equipping the room with a viewing pit, and its depth must be thought out in advance, taking into account the parameters of your own body - one must confidently fit there, not being limited in actions.

It is also important to calculate in advance the number of blocks of expanded clay concrete - it is good just when you decide to build a building from monolithic blocks. The dimensions of one block depend on the manufacturer, but usually it is 20x30x60 cm or 10x30x60 cm. Please note that only the first option is used for the construction of external load-bearing walls, and the second is a solution only for internal partitions.

To calculate the number of necessary garage blocks, for example, 6 by 8 meters, we first calculate the perimeter of the walls, and then multiply it by their height - we get the area of all the walls. We multiply the length and height of one block among ourselves - we get its surface area. We subtract the squaring of windows and doors from the total area of the wall, after which we divide the remaining area of the walls by the size of one block. It will be correct to make a stock of material of about 15% in case of error in calculations.

Construction technology

You can build a garage with your own hands, if you treat all stages of the task responsibly and with due patience.

To begin with, as in building a house, you need to clear the site by cutting down trees and shrubs and uprooting their roots. It is also advisable to mow the grass.

Foundation

A strip foundation is quite enough for a lightweight structure made of expanded clay concrete, but under the strip, you should first make the correct markup. It is necessary to draw the marking lines directly along the ground, and so that they are straight, mark the area with pegs and pull a string between them. Make sure all angles are set correctly first before digging trenches.

The pit walls must be protected from being washed away with a waterproof polyethylene film. A sand and gravel cushion is poured along the bottom, which must be spilled with water - this way it will seize more reliably. The formation of the cushion is carried out in layers with a thickness of 10 cm or more, after each layer a layer of concrete is poured, but only after the mixture of sand and gravel has dried. It will not be possible to complete the task quickly, but you should not ignore the requirement for the sake of the durability of the foundation.

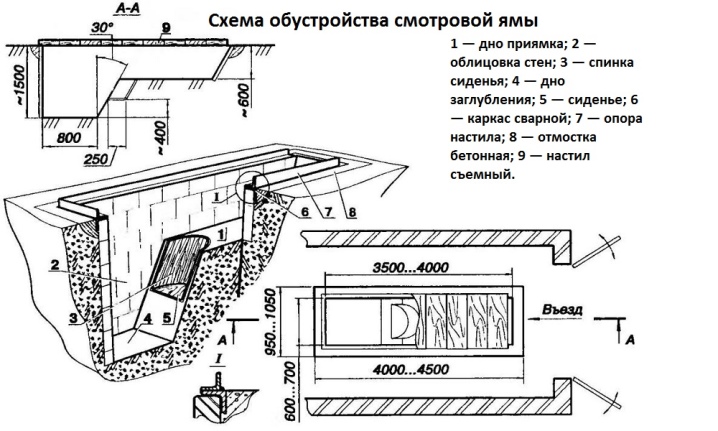

Observation pit

The inspection pit is laid immediately after the foundation is poured, or in the process of forming its layers. It is important to correctly calculate the parameters of the recess: the width cannot exceed the wheelbase of the car, and even should be 20 cm less for a comfortable drive into the garage. On average, the width of the pit comes out about 80 cm. The depth of the structure is the growth of the owner, plus about 20 cm of stock, allowing you to turn around.

Under the appropriate dimensions (but with a decent margin), they dig a pit, the bottom of which, again, is covered with a cushion of gravel, but not with sand, but with clay - it has waterproofing properties. The pillow is formed in several successive layers, after which it is covered with a film to enhance the effect. Only after that, the bottom is poured with concrete - already on top of the film.

The walls are covered with wooden formwork, which will become the basis for a reinforcing mesh - for example, a chain-link mesh. It is poured with concrete - these will be the walls of the pit.

Floor

The garage floor must be taken seriously - it will experience a much greater load than the floor in a living room. At the same time, the scheme for creating a floor in a garage is very similar to the above-described creation of a foundation, only without digging trenches. In this case, the sand and gravel cushion is also laid in several layers and spilled with water. It is not recommended to save on materials.

To increase the strength and durability of the floor, experts advise that you first lay a reinforcing mesh over the top layer of the pillow, and only then fill it with concrete. Crushed stone added to concrete will help to further enhance the effect.

Walls

You can start building walls only after all issues with the foundation and floor have been resolved. The thickness of one expanded clay concrete block will be quite enough for safety and reliability, and in general, the masonry made of such material does not differ from the brick in anything, except for the increased speed of implementation.

To lay the foundation of the walls, a procedure is performed that we did separately for the floor - a mesh is placed on top of the strip foundation, which is poured with concrete and leveled. On top of it (after the solution has solidified), blocks are laid out, the gaps between which are coated with mortar. The next row should be offset by half a block from the previous row in order to properly distribute the weight of the structure.

Accordingly, halves of blocks will be needed, you can cut the material using an ordinary grinder.

Roof

You can think of a lot of roof design options, but predictably the simplest will be the decision in favor of a pitched roof. The fundamental requirement for it is reliability, because the car inside the building must be protected from atmospheric precipitation.

To begin with, a wooden frame is made from a bar, which will cling to the walls with protruding edges on all sides so that it is not blown away by the wind. Before assembly, wood must be impregnated with special antiseptics and compounds that will make the material durable even under outdoor conditions.

When the roof frame is assembled and well fitted to the dimensions of the walls, roofing material is laid on top of it - the main heat and waterproofing function falls on it. On top of the roofing material, you can lay out any roofing material of your choice in accordance with the instructions for installing such products.

Thermal insulation and waterproofing

It is undesirable for expanded clay concrete blocks to get wet, which means that you need to take care of waterproofing, which at the same time protects against heat loss. You can protect building materials from moisture penetration with bitumen, polymer-based membranes or penetrating insulation. Each option is good in its own way.

Today, penetrating insulation is popular, which tends to push water out of the pores and fill them with itself. The processed material loses its porosity and stops absorbing moisture. Such impregnations can be used even over an already damp surface.

The membrane option is quite budgetary: at low cost, you can achieve a good level of protection for the walls. As for bitumen, it is known to builders of past generations, and although today it is no longer considered a top solution, it is still popular due to its impressive cheapness.

Now the most productive option indoors is three-layer insulation: the closest to the blocks is a foam layer, after which a layer of waterproof polyethylene is laid, and an outer, aesthetic layer of drywall complements the picture.

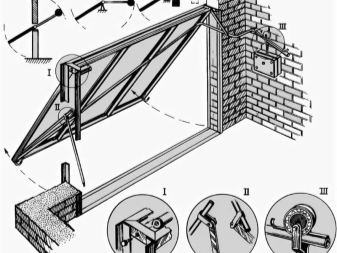

Gates

If windows for the garage are optional and may be absent in principle, then you cannot do without a gate. Today there are three main types of gates, which in any case will have to be purchased from the manufacturer - it is hardly possible to make them with your own hands. But theoretically you can hang it yourself.

-

The swinging structure consists of two leaves - this is the oldest and simplest solution, which is valuable for the extreme simplicity and durability of the structure. First, you need to weld the frame from the steel corners and fix it securely in the opening, after which you can hang the gate using the hinges. Some craftsmen make sashes on their own from a profiled sheet.

- The gates with an automatic sliding mechanism look beautiful and are a door that slides to the side, freeing the passage. Self-production of such a device is almost impossible, and you will have to spend great money. In this case, the departing door needs a place so as not to interfere with the normal life of the household and not to crash into anything.

- Lifting gates solve the space problem, which was in the above-described rollback option, but otherwise all the problems are identical.

Features of interior decoration

Only the owner himself decides how to decorate the inner walls of a newly built garage, and he can make a choice based on his own aesthetic preferences. At the same time, it is advisable to choose materials that are distinguished by impressive durability, are extremely easy to maintain and do not absorb dirt, and in the best version, taking into account basic safety precautions, they still do not burn. The last factor, however, is ignored by many builders. In view of this, the most popular are four finishing materials:

-

lining - is relatively cheap, but allows you to create an original interior;

-

PVC panels - are in demand due to their low cost, ease of installation and aesthetic beauty, but this is the least environmentally friendly material;

-

tile - expensive, but definitely the most practical option;

-

plaster - a general name for a number of finishing materials with different properties.

How to build a garage from expanded clay concrete blocks, see the video.

The comment was sent successfully.