How to make a wooden garage with your own hands?

Today, most private home owners try to store their cars, if they have any, in garages. This is absolutely understandable, because being in such a room, the car is less exposed to external natural factors and protected from prying eyes, and therefore its condition deteriorates less rapidly during operation. The garage can also be used as a storage room for storing items or non-perishable items.

Peculiarities

A do-it-yourself wooden garage would be a good solution for a private house. The territory where it will be located must be fenced, since such a building does not guarantee protection from thieves.

It should also be said about other disadvantages of a wooden garage:

- not too long service life;

- high fire hazard;

- the need for processing building materials with special substances.

They also have many advantages:

- availability due to the low price of building materials;

- the possibility of self-erection;

- ease of installation work;

- environmental Safety;

- relative strength.

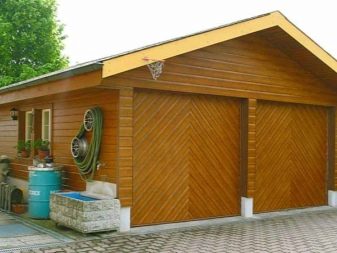

There are several types of garages made of wood. The most popular are the buildings made of timber, which is the most durable and durable material.

But it is not easy to build a log house on your own, and its price is quite high.

At the same time, a log garage is considered a reliable structure, and outwardly it looks quite presentable.

Garage buildings made of rounded logs are also common options. They also look great. In this case, you can purchase ready-made building materials that are assembled according to the principle of a constructor.

The third category is frame-based garages. It is on the frame that the main load will fall. But the main advantage is that any facing material can be used. If you wish, you can make a garage from a profiled sheet, and also from wooden boards or any other glued wooden material that is at hand.

Blueprints

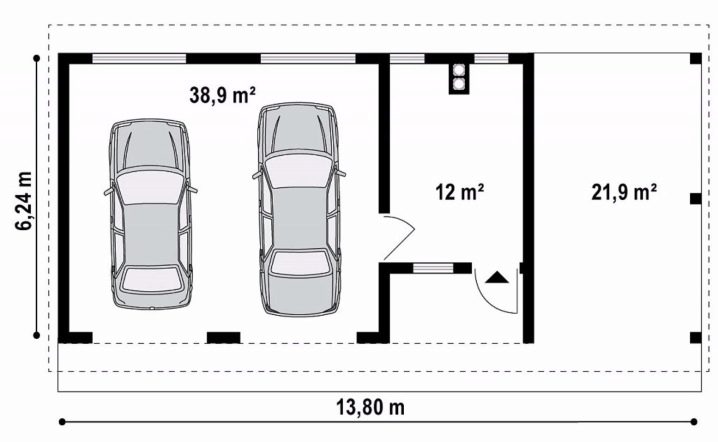

Many have problems with the construction of a garage at the design stage. This is not surprising, since this process is the most difficult. The fact is that its importance lies in the need to think over the design as much as possible, because the parameters of a structure for 2 cars will differ significantly from the characteristics of a garage structure for one car.

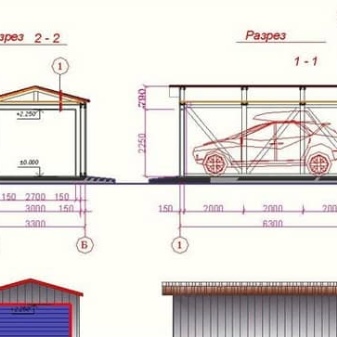

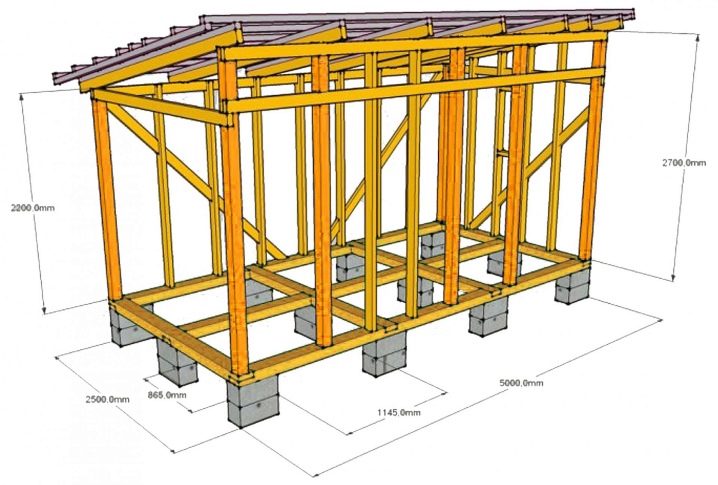

A standard garage usually has dimensions of 6 by 4 meters.

Its height will be about three meters. But a garage of 6x4 m is a standard indicator. It will not be possible to fit two cars into it, and there will be more than enough space for one. But it all depends on the characteristics of the car itself.

If you need to calculate the parameters yourself, then when taking into account the dimensions of the car, you need to add 50 centimeters on the sides to open the doors, one meter from the trunk side and about 60 centimeters on the other side. The height is determined by the growth of the owner and in addition 1 meter is added to it.

Calculation of the amount of materials

After the person has decided on the size, a garage project is done. It takes into account all the little things and nuances that can be encountered when erecting such a structure.We are talking about such things as the placement of lighting fixtures, driveways, paths, how the gates will open, what category they will belong to, and many other important nuances. The project must necessarily reflect the type of building - whether it will be an extension to the house or an independent construction. Depending on this, the amount of required building materials will be different.

Another factor that influences this moment is the technology chosen for the construction.

If we are talking about a frame model, then it is necessary to calculate how much profiled timber of different sections, insulation, OSB sheets, metal corners, self-tapping screws, wood and other materials are required.

If the garage is built using log technology, then you need rounded logs and insulation. You also need to think about what materials for the roof will be used.

Preparation

After all the calculations have been completed and rechecked, a place should be prepared for future construction. To do this, you need to perform the markup. It can be done with pegs and twine. After that, the territory is cleaned from garbage. If there are slopes or elevation differences on the site, then they should be raised so that the ground is level.

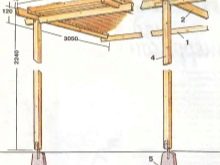

After this is done, preparatory work begins. The foundation should be poured first. The most popular are pile or columnar foundations. They are used for lightweight buildings and are pillars or piles that are mounted around the perimeter of the future garage in the ground.

Piles are either jellied or ready-made. If the second option is planned, then wells are also needed.

For self-construction, it is better to make flood piles - for this you just need to execute the mortar and pour it into the holes prepared in advance. All these works are cheap, and no special knowledge is required here.

Construction

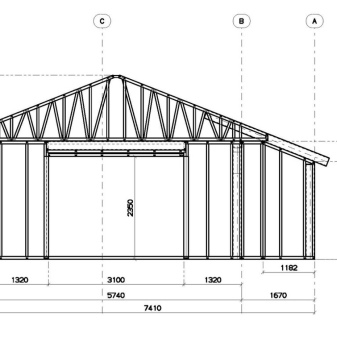

The first stage, which determines the success of all further work, is the construction of the frame.

It consists of three elements:

- top strapping;

- racks;

- bottom strapping.

For the lower strapping, a bar with a section of 100x50 mm is used. The racks are made of 150x150 mm timber, and the floors and rafters are made of 100x50 mm mini-timber.

A garage floor made of logs is laid on the lower strapping, under which a layer of roofing material should be placed.

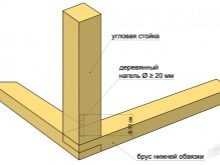

The embedded beam is fastened at the corners in one of two ways:

- on a plug-in thorn;

- in the paw.

It is worth remembering that the bond must be strong and reliable. After that, the so-called logs are inserted into the lower harness. This process is performed every 40-45 centimeters.

If the length of the lags is very large, then it is possible to carry out the installation of supports along the entire length, which are easily made from brick posts. This must be done so that the floor does not sag under the weight. The distance between them should be no more than 60 centimeters. They should also be covered with roofing material. By the way, all wooden elements, including bars and logs, should be pre-treated with an antiseptic.

After that, you can proceed to the construction of walls. Here the connection of the timber will be the same as used earlier.

The rows are attached to each other using so-called dowels - they are called hardwood wedges, which must be driven into holes drilled in advance. The dowels are sunk into the boards so that cracks and holes do not form anywhere during drying. In the upper rim, cuts are also made for building blocks.

As for the roof, its shape will depend on the design and size of the garage structure. Usually it is either single slope or gable. If the garage is adjacent to the house, then it is best to make a pitched roof. If it is a separate building located at a distance from the house, then the gable option would be the best choice.

After the roof is made, its lathing is performed. A waterproofing layer of roofing material is placed across the lathing, and only after that the roofing material is already laid.

Then you need to return to work on the floor.

It is best to make floors from grooved boards, which are fixed on the joists.

They should be fixed on the logs with self-tapping screws, or you can nail them with large nails, because the floor has to withstand the weight of the car, and this, as a rule, is more than one ton.

When the floor is ready, it should be completely covered with a special fire-fighting compound., which will significantly increase the resistance of wood to high temperatures. And to further secure the building, the floors can be covered with metal sheets. If it is not financially possible to cover the floors completely, then this should be done at least in places where there is the greatest likelihood of a spill of flammable and flammable liquids.

Such step-by-step instructions will easily allow you to create a garage quickly and relatively cheaply, and most importantly - on your own.

Tips & Tricks

Below are tips and tricks to make your garage more functional and convenient.

If the garage is adjacent to a two-story type cottage, then it is best to make a staircase that would allow you to enter the house from the garage, and for certain types of house and garage construction - to the second floor. This approach is quite convenient, since it allows you not to leave the garage on the street, for example, in cold weather, but immediately get home.

Also, a fairly common solution for many summer residents is the presence of a connection between the garage and the basement, which is located under the house. But here, again, everything will depend not only on the design of the house, but also on the garage itself. Many summer residents make a hole in the garage, which should be in any building of this type, and simply break through a passage into the basement, which is closed with tight doors.

This is very convenient, as it allows you to transfer fruits, vegetables and canned food directly from the basement or cellar to the car in order to transport them home later.

If the car owner loves comfort, then a mobile gate will be an interesting option for him. This is a fairly popular option among motorists, because it uses automation, which allows you to open and close the gates without leaving the car using the remote control.

As you can see, building a garage with your own hands is a very real thing. The main thing is to clearly calculate everything to the smallest detail: what is needed to build a garage, what are the building needs, to know the type of car that will stand in the garage, and to understand why such a structure is needed.

It should be remembered that even professional builders make mistakes, and therefore no one says how everything can turn out.

But with correctly performed calculations, high-quality building materials and at least minimal building skills, even a person who has never previously had experience in building such objects will be able to make a high-quality, functional, spacious and aesthetic, in terms of appearance. Everything will definitely work out if you follow the tips that were presented above.

For information on how to make a wooden garage with your own hands, see the video below.

The comment was sent successfully.