What is better for bedding - percale or poplin?

In the presented variety of fabrics used today for the manufacture of bedding sets, it is sometimes quite difficult to understand. Among the materials that most often act as raw materials for sewing, percale and poplin are in special demand.

To have the most complete understanding of these fabrics, you need to consider in detail their characteristics, advantages and disadvantages.

Tissue similarities

The selection of bed linen only at first glance may seem like a fairly simple event, however, in fact, the possibility of a good rest will directly depend on the choice made. Sleep is the key to successfully replenishing the spent energy, and the material from which the sheet, pillowcase and duvet cover will be made will directly affect the comfort of spending time in bed.

Poplin and percale sets have long been in great demand, due to such a preference for a number of characteristics of these fabrics. First of all, it is worth noting that the materials have a certain similarity with each other due to the fact that natural cotton threads are used as raw materials for their manufacture.

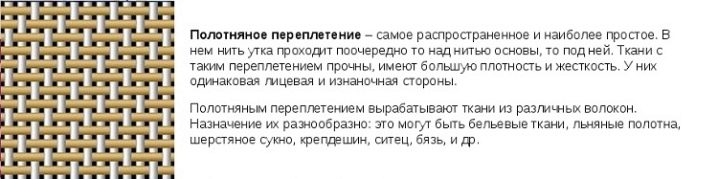

Poplin and percale have almost identical density indicators, which determines their good wear resistance during active operation of ready-made sets. The production of these materials takes place by means of plain weaving of cotton threads. With a multiple increase in a piece of material, one can note some similarity of the canvas with a chessboard, since the main threads are intertwined with the secondary ones one through one.

In terms of appearance, both are attractive and available in a wide range of colors.

Fundamental differences

Despite a certain similarity of fabrics, they still have a number of unique features that allow these materials to be attributed to different types of raw materials used for sewing textile products for bedrooms.

First of all, one should dwell on the history of the origin of the two materials. A material such as poplin began to be produced in France several centuries ago. For the first time, it was received specifically for the Pope, which gave rise to its name.

Regarding the second material, we can say that it began to be made in the East - in hot India, where it was of particular importance for textiles to bring much-needed coolness to the body.

Despite the rather unpleasant name of the material, and percale in translation means "rag", in a very short period of time the fabric has become in demand not only at home, but also far beyond its borders. And French weavers and needlewomen, having adopted the experience of Indian masters, began to make percale in their workshops and sew from it a variety of products for the home, as well as casual clothes for men and women.

A notable difference between the materials can be considered the thickness of the threads used for the production. Percale is made up of thicker cotton weaves, in addition, the fibers are combed out in a special way, but not twisted together.

Another specific feature of the production of fabric is the coating of the fibers with a special substance that has the ability to glue cotton threads to each other.Such methods have a beneficial effect on such an indicator of raw materials as strength.

From the long history of percale, one can note such a remarkable feature as the use of fabric for the manufacture of parachutes, which speaks for itself about the strength of raw materials and finished products from it.

Sizing with an adhesive also has a beneficial effect on the ability of the material to maintain its original appearance for a long time, since the agent prevents color loss from exposure to ultraviolet rays. In addition, it prevents the fibers from fluffing, which makes the products smooth and pleasant to the touch for a long time. But percale products wrinkle rather quickly, which makes it necessary to iron bed linen from such raw materials.

From the above, we can conclude that percale is a light, but at the same time durable fabric; it differs from poplin in a higher cost. Average the service life of percale bedding sets is ten years.

Poplin almost does not wrinkle during operation, it is considered an exquisite material with a more porous weaving structure, since cotton threads do not adhere so much to each other during production. But the bed poplin linen will be usable for no more than five years.

Making material such as poplin, occurs by weaving cotton fibers, sometimes with the addition of synthetic raw materials different levels of density. This method of production determines the unique surface structure of the material - it is covered with small scars.

Poplin is widely used not only for making bed linen, but also for sewing tablecloths, towels and clothes.

On sale you can find poplin products, which include silk and even woolen threads. It is these types of material that are in demand for sewing elite and high quality bed linen.

To check the composition of the product, you should familiarize yourself in detail with the label on the product, in which manufacturers indicate the presence of natural and synthetic fibers in percentage.

Comparison of advantages and disadvantages

To get an objective idea of the materials used for sewing linen, it is necessary to consider in detail the positive and negative aspects of each of them.

As for percale products, the following features can be considered the advantages of the products.

- Long operational life... As practice and numerous consumer reviews show, percale demonstrates high wear resistance in comparison with most cotton products for bedrooms. This advantage is explained by the density of the threads of the raw material, which is about 140 g / m2, which is several times higher than similar indicators of other natural fabrics.

- Durability of products... Even after numerous washes in washing machines and irons, bedding does not lose its strength, which minimizes the risk of holes in the products.

- Ability to maintain the brightness of the applied pattern and the original form. Experience shows that the fabric does not deform under the influence of mechanical factors, and is also not susceptible to the formation of pills and fading of colors after washing.

- Comfort of use of the material. Since the method of twisting cotton fibers together is not used in the process of making percale, this increases its softness, making the linen more pleasant. In some cases, you may notice a slight sliding effect of the body on the surface of the percale sheets.

- The material does not cool. Such products can be used in the cold season without fear of freezing, since they maintain the temperature, but they are perfectly air-permeable, which has a cooling effect when used in summer.

There are also disadvantages to percale bedding.These include the fact that the fabric still wrinkles during use, therefore, after washing, regardless of its method, the product will need to be ironed.

Recently, some manufacturers, during the manufacture of steel material, additionally include synthetics in its composition, which can adversely affect the characteristics of the finished product, in particular, complicate air exchange. As a rule, on the label of such kits there is a corresponding designation - mixed percale.

Dwelling on the advantages of poplin and products made from it, such features should be noted.

- Material strength... During operation, cases of wear and tear of products, even such as a sheet on family and children's sets, are quite rare.

- Products are perfectly breathable... Thanks to good air circulation, the body can "breathe", which increases the hygiene of the textile products.

- The fabric is excellent at accumulating heat... The products will not cause discomfort when used in winter.

- Large selection of products... Today manufacturers of bedding sets offer products from printed, plain dyed and multi-colored poplin, which allows you to choose products for your individual preferences regarding appearance.

- Hypoallergenic material... Poplin bedding is allowed for use in the presence of various skin ailments without fear of developing unpleasant reactions of the dermis upon contact with it.

- Easy to care for products... A positive feature of textiles is considered undemanding in terms of the use of any special means for washing.

- Resistance to deformation... Such products do not wrinkle after washing, in addition, they do not lose color.

- Texture softness... The material is very soft and silky, so it is pleasant to contact with the body while sleeping.

Among the disadvantages of poplin bedding, it is necessary to highlight the cases when the purchased products with an admixture of wool or silk in their composition after washing gave a decent shrinkage.

Which is better?

It is rather difficult to give an unambiguous answer to the question of which of the materials under consideration will be the best, since in the matter of choosing such products, each buyer is guided by individual preferences, evaluating certain characteristics of the fabric.

However, taking into account the fundamental properties of materials, it should be borne in mind that percale will still surpass poplin in thread strength, due to the use of a special composition in the manufacture. Hence, its higher resistance to abrasion during operation follows. Density is also important, but if there is a need to purchase thinner items, poplin should be preferred.

For those who do not like ironing, it is recommended to opt for poplin sheets and pillowcases, since they will not need to be steamed after washing.

For consumers, whose primary question is the price of a set of bedding, it is worthwhile to dwell on poplin products, the cost of which will most often be much lower. But their service life will also be shorter, which is important in terms of the expediency of the purchase in terms of savings. Particular attention should be paid to bedding sets that contain additional synthetic impurities, since artificial fibers can significantly affect the features and benefits of natural fabric.

Bed linen is a thing that is constantly in use, therefore, in some cases, the durability of percale is still a more significant advantage over poplin. In light of the large number of low-quality textile products that have appeared on the market, special attention should be paid to the seams of the products, they should be made to match the set, as well as the smell of the new set, which should not contain harsh chemical impurities.

More information on the difference between poplin and percale in the next video.

The comment was sent successfully.