Towel rail fittings

Modern models of heated towel rails barely resemble Soviet classic products, which were called coils. Then such devices were an element of the heating system of the entire apartment. Today, a heated towel rail primarily heats the bathroom in order to avoid the appearance of mold and mildew in such a humid room.

In addition, it is used to dry a variety of clothes and bath accessories. But there was also an aesthetic component. And here it is very important to use the right components. In particular, fittings for heated towel rails. Let's try to figure out what kind of element it is, what it is and how to pick it up.

Characteristic

Fittings are required to secure the structure of the heated towel rail, as well as to connect to a hot water source and the normal operation of the entire system in the future. They are usually made from the following materials:

- copper - it has the highest thermal conductivity characteristics, but also the highest cost;

- stainless steel - such stainless steel parts have an excellent appearance, as well as are durable and reliable;

- chrome plated brass.

It should be said that chrome plating of parts in this case is done in order to form a protective oxide-type film, which does not allow iron to react with oxygen and form rust. Besides, chrome-plated parts, thanks to their silvery white color with a bluish tint, have an excellent aesthetic component.

In addition, this metal is quite hard, which makes it possible to give the product additional strength.

Views

To connect the dryer, serious attention must be paid not only to the selection of material for the mentioned structure, but also to the fasteners, that is, fittings. Not only the external design will depend on them, but also the functionality and practical characteristics of this system in the bathroom. If we talk about the types of fittings, then they are of the following categories.

- Detachable extension cord. It allows you to adjust the distance between the dryer and the wall where it will need to be attached. Such fittings are used as a kind of a kind of base, for connection with which a pair of fasteners is required. They are attached only in front of the pipe bends. The mentioned type of connectors has one drawback - the thread is too long in length. But it can be undermined.

- Cross fitting. With the use of such a device, it is possible to separate the mechanism in 2 directions.

- Reflectors. This type of fittings prevents moisture from penetrating to the mount.

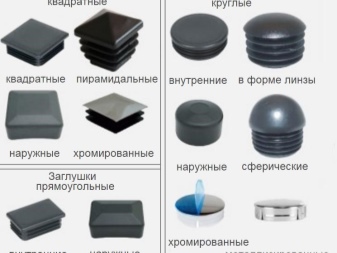

- Plugs, caps and plugs allow to seal pipes.

- Corner or corner faucet. Designed to connect a heated towel rail to heating. Fittings like these make it possible to change the direction of the pipes. Depending on what dimensions the pipes have, you can select the required diameter of such corners.

- Tee. This type of connector comes in handy when branching off the main pipe is required. This type of fitting will allow you to directly connect the riser and heated towel rail. The presence of a bypass should also be taken into account, which makes it possible to turn off the heated towel rail, if necessary, without creating inconveniences with heating in general.

- "American". This is a type of fittings with taps, allowing the dismantling of the structure when required.The convenience of this type of device is that it is not required to turn off the entire system. It is enough just to close such a valve, unscrew the nut and dismantle the structure. By the way, the nut here can be different - a nut with a union, a couple of nuts, a couple of fittings.

- Turnbuckle. Carries out almost the same functions for a water heated towel rail, as the "American". True, there is still one difference - it has different diameters at different ends, which makes it possible to connect pipes of different dimensions. The difference can be significant and can be 1 inch or more. The thread of the shrink-type coupling can be both external and internal.

- Polymer winding. This option of fittings makes it possible to protect yourself from the occurrence of backlash, which may appear on the adjusting type connections. If it is possible to carry out the winding of the reel correctly, then it will be able to take the required form.

It should be borne in mind that this part will not seal over time.

Choice

If we talk about how to choose the right fitting, then you should be guided by the following aspects:

- compatibility of the heated towel rail and the material from which the fitting is made;

- compatibility of diameters of domestic-made fittings and heated towel rails made abroad;

- fitting coating (best of all, it should be chrome-plated);

- appearance;

- manufacturer - there are many not only foreign firms, but also domestic companies that produce high-quality fittings.

Separately, it should be said about the moment with the pipe diameter and the selection of fittings. It is necessary to ensure that the diameter of the riser is not less than this indicator for the heated towel rail at the connection point. It will be best if they are equal. True, it is allowed that the riser is larger than the pipe of the device. But then you need to make jumpers. If we talk specifically about pipes for dryers, then their dimensions can vary.

- For devices made in the form of the letters "M" and "P", pipes with a diameter of 0.25 centimeters or three quarters are usually used;

- Pipes 1 with an outer diameter of 0.32 cm are also used. They are suitable for most solutions, including ladders with foxtrot.

- Diameter 0.4 itself will fit a pipe 1/4. It is usually used when installing foxtrots and solutions in the form of the letter "P". A similar pipe diameter is not found in other devices at all, because it is extremely difficult to bend a pipe of this size.

Connection methods

Methods and options for fastening, based on the types of fittings, the following can be noted.

- Threaded method. The most commonly used connection type. The main advantage will be that the slicing process is not difficult. Any developer can make a threaded connection on their own. Among the disadvantages should be called not very good tightness and the fact that when exposed to high temperatures, the metal is susceptible to corrosion. But the threaded connection method is considered a classic.

- Compression option. For fixing, a crimp ring is used here, which is fixed to the pipe using a fitting. The strength of this technique is that it can be applied to pipes made of any material. The method is convenient in terms of availability. The disadvantage of this method is low reliability.

- Pressing technique. It differs from compression fittings in that you need to use press fittings to install everything you need. Minus - the need to use additional equipment. But the reliability here will be higher than with the compression technique.

- Capillary brazing. It is used exclusively when installing metal pipes. Then a wire is pulled between the pipe and the fitting. When heated, it straightens out and fills the gap between the connection elements. This is the most balanced and durable fastening method. But it is very difficult for a layman to implement it.

- Self-locking fittings. They are equipped with special rings on the surface inside. When connecting pipes, fixation is carried out due to the large number of teeth. This mount is considered to be very reliable and good. This solution is easy to assemble and disassemble. Its advantage will be its high speed of formation.

How to tighten the fittings for the heated towel rail, see the video below.

The comment was sent successfully.