What is polyurethane and where is it used?

Polyurethane was first heard of in 1937. This material was synthesized by Otto Bayer from diisocyanate and polyester in liquid form. The substance had a lot of advantages over plastic, which at that time was quite in demand.

What is this material?

Polyurethane is a unique type of material that has almost unlimited possibilities and prospects for use. The polymer contains 2 types of raw materials, namely: polyols and isocyanates. The production of the latter is based on oil refining. By mixing liquid elements, reactive compositions are obtained. The properties of polyurethane directly depend on the ingredients from which it is made, as well as on the ratio of catalysts, blowing agents, stabilizers and much more.

Polyurethane looks like a polymer fiber with a porous structure. It is considered a versatile elastomer, but it has both advantages and disadvantages.

The advantages of polyurethane include the following characteristics:

- high mechanical strength;

- dielectric constant;

- poor abrasion;

- good elasticity;

- the ability to maintain shape after repeated deformations;

- wear resistance;

- long service life;

- resistance to acids, oils, solvents;

- non-susceptibility to the influence of microorganisms;

- large operating temperature range;

- resistance to low temperatures;

- the ability to work under high pressure.

This material does not age, it lends itself to various types of machining. In addition, polyurethane products are lightweight and therefore easy to transport and install. This elastomer has the ability to foam, so all kinds of porous products are made from it.

Despite the many advantages, polyurethane has some disadvantages:

- unstable to torsion loads;

- the elasticity and strength of the material directly depend on the temperature regime of the environment;

- the complexity of processing into secondary raw materials.

This type of elastomer refers to materials that are easily amenable to all kinds of processing. Various methods of shaping are applied to it.

- Extrusion. This method of obtaining polyurethane involves forcing the material in molten form through the forming hole of the extruder.

- Casting. Under the influence of pressure, the molten mass is injected into a special mold, after which it is cooled.

Comparison with rubber

Despite the fact that rubber and polyurethane are quite similar, synthetic elastomer surpasses natural material in quality characteristics. Unlike rubber, polymer fibers have higher strength and wear resistance. For this reason, rubber is used less than polyurethane in many industries. The main factor affecting the durability of the material is its abrasive wear, susceptibility to the influence of an aggressive environment. When comparing according to this criterion, it can be concluded that polyurethane is 10 times more resistant to abrasion.

According to the assessment of resistance to different environments, the polymer is also considered to be better than rubber. It can tolerate the effects of solvents and toxic chemicals.Among other things, natural rubber has a tensile strength 1.5-3 times lower than that of an elastomer. The synthetic material is able to quickly recover its shape without deformation in the event of a high load. Rubber, in turn, is superior to elastomer only in cost, which is much less than that of synthetics.

However, according to experts, in order to avoid the need to pay twice in the future, it is better to buy high-quality and expensive material.

Characteristics and properties

Since polyurethane is based on polyol and isocyanate, it belongs to the group of polyester polyols. Due to the fact that this type is an elastomer, it is characterized by good extensibility and the ability to return to its original forms. Various additives can impart unique properties to polyol, which can change the indicators of elasticity, softness, hardness, resistance.

Polyurethane is produced in several states:

- in a viscous liquid;

- in soft;

- in solid.

Regardless of the shape, the elastomer does not change its technical characteristics under the influence of mechanical and chemical environmental factors. This material is also resistant to UV radiation, fungi and mold.

The technical features of polyurethane allow it to be used in many household and industrial areas. Let's list the main characteristics of a polyester polyol.

- Density. The indicator depends on the type of material, usually it ranges from 30 to 300 kg / m3.

- Hardness. On the Shore scale, it can range from 50 to 98 units. These indicators allow the elastomer to be used at high loads.

- Significant temperature range. The material can be operated at temperatures from -60 to +80 degrees Celsius. With an indicator of 120-140 degrees, it can be used for a short time. Polyurethanes have a high melting point - at least 160 degrees Celsius. If these materials are heated to 220 degrees, then they will begin to decompose.

- Thermal conductivity coefficient - 0, 028 W / (m * K).

- This polyol has no electrical conductivity.

- Weight. The material weighs very little.

- Ozone resistance. Polyurethane does not degrade under the influence of ozone, unlike rubber.

- Resistance to aggressive environments.

- Flammability. According to GOST 12.1.044, the material is classified as non-combustible, therefore it is used in many industries.

- Environmental friendliness. Polyurethane is classified as a safe material, so it is often used in everyday life.

Is polyurethane harmful?

Due to its energy-saving characteristics, polyurethane is classified as a safe material. However, when evaluating its environmental friendliness, it is worth taking into account the possibility of harm to this elastomer in the liquid and solid state. As practice has shown, in dry form, this polyol does not emit harmful substances. Hazardous vapors are only possible if the material is handled incorrectly.

If all safety measures are observed in the liquid fraction, polyurethane will not pose any danger to people and animals.

However, violation of production technology may result in the release of the following toxic fumes.

- Isocyanates... These substances are part of paint and varnish, foam products. Their presence can cause asthma in the absence of special protection.

- Amine catalysts, which cause increased sensitivity, irritability, blurred vision. When inhaled continuously, these substances cause ulcers, irritation of the mucous membranes, burns to the mouth, throat and esophagus.

- Polyol. He is able to manifest his toxic effect only in direct contact with a living organism, namely when swallowing. Polyol poisoning manifests itself in the form of vomiting, intoxication and spasms.

- Fire retardant. This substance gradually accumulates in the body, after which it causes poisoning.

As a result of the above, we can conclude that polyurethane can only be harmful to health if it is used improperly. This often happens when using low-quality types of spray, as well as in the absence of special protection during operation.

Many are worried about the dangers of polyurethane, which is mounted in residential premises. The fears of users are in vain, since this category of goods undergoes a lot of safety tests before going on sale. Problems can only arise if the elastomer is purchased from a manufacturer that does not have quality certificates.

Comparison with other materials

Knowing about the characteristics of polyurethane, we can say that it has much more advantages than rubber. As already mentioned, this polymer surpasses it in durability, extensibility, strength and many other characteristics. Consumers often find it difficult to choose between polyurethane and other similar products, comparing it to them.

- Duropolymer. Has the appearance of a matte plastic product. In turn, the polyurethane is similar to a foamed powder and is coated with a primer. The latter is lightweight and is great for working with ceilings. In addition, its assortment is quite wide. Duropolymer belongs to anti-vandal polymers, so the buyer does not have to think about its restoration for a long period.

- Vinyl. This material, unlike polyurethane, is not intended to protect the surface, it is more often used for decorative purposes.

- Silicone. These materials are produced for use in various types of work. According to consumers, the elastomer is characterized by better durability and strength. In turn, silicone is distinguished by the fact that it is elastic and bio-inert.

- Expanded polystyrene. The difference between the materials lies primarily in the cost, which is higher for polyurethane. Expanded polystyrene does not conduct heat well, it is convenient and easy to use. Polyurethane lasts longer than the previous material, does not deteriorate under the influence of negative environmental factors.

- Polyester. With it, polyurethane has many of the same properties. However, in some way the second material is superior to the first in quality. Polyurethane is more elastic, stronger and more durable than polyester.

Species overview

Polyurethane is a transparent energy efficient universal material that is gaining popularity around the world every day. This material has its own special marking. The most popular brands of elastomer include SKU-PFL-100, NITs PU-5, they are characterized by a Shore hardness of 85-90 units.

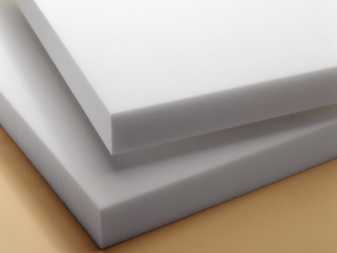

Flexible polyurethane foam

It is customary to use flexible polyurethane foam rubber as a shock absorber. In addition, it is used to create bedding, lining, packaging, and automotive interiors.

Flexible foam can be created in any form. This type of polyurethane is characterized by lightness, strength, and comfort.

Thermoplastic

Thermoplastic polyurethane is an elastic, flexible material resistant to abrasion and adverse weather conditions. It is produced and colored by various methods. Thermoplastic elastomer processing is carried out on extrusion, compression, impact machines. This flexible product is able to adapt to various applications such as construction, automotive, footwear.

Applications

Polyester polyol is widely used nowadays. Lining items, press parts, roller, wheel, roller coating, sealing rings, cuffs, plugs are produced from polyurethane sheets. In liquid form, it has found its application in the coating of concrete structures, wagons, hatches, and roofs. Often, the elastomer is part of a sealant, glue, paint and varnish products.

In heavy industry, shock-absorbing parts are made from this material. In construction, it is used to create an anti-slip coating, vibration-resistant surfaces, facades. The automotive and furniture industries are indispensable without elastomer. The demand for polyurethane is observed in the textile industry. It is suitable for making covers, zippers, rivets, insoles, soles. Medicine uses elastomer for the production of condoms, prostheses, and implants.

Processing

Nowadays, the issue of recycling polyurethane is becoming increasingly important. The problem is associated with an increase in the area of landfills, as well as an increase in the cost of their removal. In recent years, the development of the latest technologies for the processing of elastomers has been observed and more and more attention is paid to this issue.

Here are the main methods for obtaining recycled materials from polyurethane.

- Physical. In this case, the plastic is crushed to a fine fraction, which is subsequently used as a filler in construction.

- Remelting. The result of this method is the production of raw materials, which are subsequently used to obtain polyurethane products.

- High heat glycolysis. Using this method, carbohydrates are broken down.

- Chemical. Processing is based on depolymerization, after which substances with a low molecular weight are formed from the elastomer.

- Burning. This method of obtaining energy is considered the most dangerous of all of the above, since it releases harmful substances into the atmospheric air.

Thanks to the extensive introduction of recycling, the current problem of the use of polyurethane can be solved. The properties of this material are diverse, they practically have no boundaries. The elastomer functions perfectly not only in a domestic environment, but also in extreme conditions.

Despite the fact that this is a synthetic substance, it is safe for humans, therefore it is used in medicine, construction, textile and footwear industries. Despite the high cost compared to other materials, polyurethane pays off with its reliability and durability.

In the next video, you will find more information on the use of polyurethane.

The comment was sent successfully.