All about Rupes polishing machines

Wood or car body polishing is carried out using special equipment. Each manufacturer offers its own line of models for different tasks. It is necessary to carefully select the modification and evaluate its main characteristics.

Peculiarities

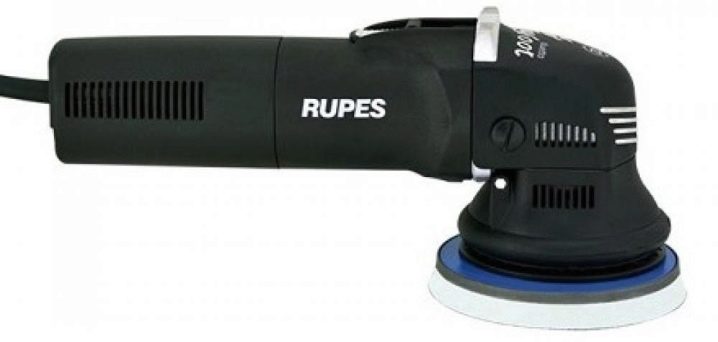

Rupes high-end polishers are relatively lightweight. Their developers were able to come up with a completely ergonomic design that does not create unnecessary noise during operation. Long mains cables dramatically increase flexibility, and carefully selected materials ensure long-term performance. The company's products are distinguished by their high power. Also important advantages of the products can be considered a well-thought-out pairing of working parts and comfortable placement of control elements.

The company began its work in 1947. All this time it has been successfully developing, constantly creating and mastering new technologies. Rupes is now firmly associated with innovative high quality manufacturing. There are 3 factories, Rupes cooperates with 160 distributors in dozens of countries around the world. Thanks to well-functioning work, it is possible to achieve an excellent result.

The group's developers always use balanced design solutions. The technical parameters are invariably aimed at achieving an optimal result. The supplied tool is initially designed for the most intense and strenuous operation. It is equally important that these devices create minimal noise and almost do not vibrate. The eccentric strokes are kept at a stable frequency even under heavy load.

Also provided:

- electronic control of the rate of rotation of the motor;

- temperature control;

- reliable brake for the sanding pad.

Grinding and polishing parts are manufactured using strictly patented technologies. As a result of their application, the notorious "salting" of the abrasive is significantly reduced. Therefore, the average product life is 30% longer than that of the products of competing companies. The abrasive elements are attached to the trays using a special kind of velcro. Such a connection is very stable during the work itself, however, at the same time, it also makes it easy to remove the tool if necessary.

Full polish has just gotten better with the addition of Big Foot. This rotary orbital processing technology provides superior success in a single pass. As a result:

- working time is reduced;

- energy costs are reduced;

- fewer consumables required.

Thanks to careful engineering, Big Foot can operate with no more than 500 watts. Consumers note that polishers using this technology do not vibrate, and also have an impeccable balance. As a result, control over the tool is almost absolute, and the polishing part moves in the most maneuverable way. The strong point of such a system is the increase in the eccentric stroke. It helps remove holograms.

Model LH 18ENS

This design has an excellent power of 1100 watts. Importantly, the excellent technical characteristics did not prevent the polishing machine from being lightweight. Due to the maintenance of uniform power, the work is as convenient as possible. Users can adjust the RPM in the range of 750-1800 revolutions per minute. It is noted that the product is quite light, and also does not create excessive noise.

From other reviews, the LH 18ENS has worked well for a long time. In addition to the stability of the equipment itself to long-term operation, its positive side is the minimum operator fatigue. In the production of the polishing machine, high-quality plastic is used that does not emit an unpleasant odor. An important positive feature is the zero risk of hand slipping. It is also worth noting the long (5 m) power cord.

LHR 15 / STD

This version of the polisher is equipped with a Big Foot complex. As a result, the eccentric device successfully removes foreign inclusions and holograms on the surface of the car. The device is equipped with a relatively compact, energy-efficient motor. The rotation rate can be flexibly adjusted. Provides the most smooth start and anti-spinning function.

With a sole diameter of 15 cm, the eccentric pitch is 1.5 cm. The motor can make from 2500 to 4700 turns per minute. The total weight of the LHR 15 / STD polishing machine is 2.25 kg. The basic delivery set also includes a branded outsole. The manufacturer states that this version:

- works very well in hard-to-reach places and depressions;

- it is distinguished by the balance of electrical loads and mechanical components;

- easy to use in any location;

- practically does not make noise during operation;

- allows you to adjust the speed using the electronic unit.

IBrid Model

This type of polishing machine is excellent for more than just the main task. It also cleans well and removes imperfections from the surface. The device can be operated from the electrical network and from the rechargeable battery. You can use two types of eccentrics - 0.3 and 1.2 cm.The polishing machine is compatible with 3 and 5 cm discs.

The twisting speed varies from 2 to 5 thousand revolutions per minute. When using a battery, the continuous operation time is 30 minutes. An adapter is provided with which the attachments are attached. There are a couple of brushes that vary in hardness. Judging by the reviews, this version helps to perform restorative polishing, removes holograms in a matter of minutes.

You can find useful and interesting information about the RUPES BigFoot polishing system in the following video.

The comment was sent successfully.