What is shrink wrap and what is it like?

Polymeric materials are deservedly considered versatile and advanced. Due to its characteristics, polyethylene film has been a serious competitor to other packaging materials for many years. What are its advantages and benefits?

What it is?

It's hard to imagine an industry today that doesn't use polymers. Polyethylene turned out to be one of the most convenient, therefore it quickly and firmly entered everyday life. It also transfers its unusual properties to shrink film - the most popular packaging option.

The chemical industry is on a special account, therefore the production of products and materials from polyethylene is regulated by separate norms. The manufacture, use and storage of shrink film is described in the document GOST 25951-83. For example, the composition, temperature characteristics, properties of certified materials, the packaging method of the film itself, and even storage features are described.

Only a manufacturer who complies with all these conditions is able to guarantee the safety of the film for employees of enterprises and end users - all people who somehow work with this material or use it every day.

The composition of polyethylene affects its density, transparency and strength. The name "shrinkable" film is due to its specific temperature properties. For example, it remains stable at + 30º-50º С - it does not decompose or deform. It is to this level that the air is sometimes heated in the hot season. If the film is exposed to a high temperature (shrinkage in industrial conditions is achieved by heating + 120º-150º С), then the material begins to change its shape. It becomes plastic and shrinks or shrinks. With this effect, polyethylene repeats the contours of objects, wrapping them like a dense knitted fabric, and not in contact with these very objects. Thanks to this effect, it is possible to tightly pack goods of various shapes and characteristics.

The packaging has unique properties: it is sealed, resistant to mechanical damage, forms a dense and strong frame, inside which, if necessary, you can securely fix such items as cans, bottles or bags. Through transparent polyethylene, it is easy to see the contents without opening the protective container, to see the marking, color, condition.

With such useful qualities, shrink film weighs much less than cardboard boxes or wooden pallets, and is much cheaper.

The only drawback - long-term decomposition - is compensated by the fact that polyethylene is recycled and reused in production.

Applications

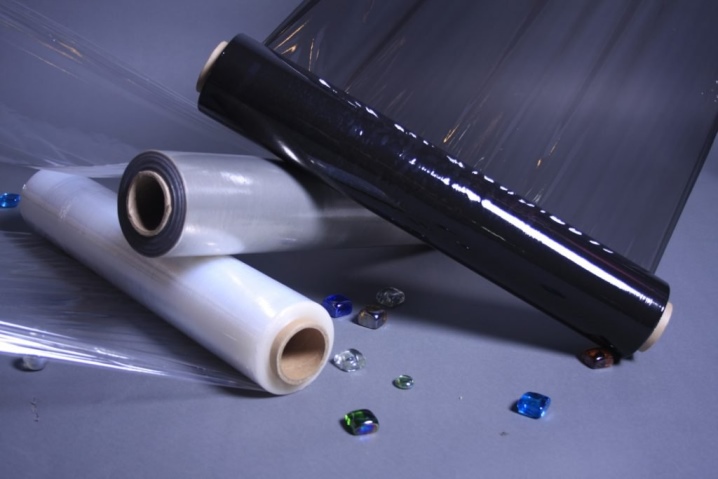

Shrink wrap is available in several forms: sleeve, half sleeve and canvas. The desired option is selected according to the size of the objects and the purpose.

It is convenient to use polyethylene for packaging goods, because:

- the film reliably fixes fragile goods (for example, eggs), hand-made products that require delicate transportation;

- packaging protects goods from mechanical damage and chips;

- polyethylene protects against dust, moisture and dirt;

- great for grouping and moving loads.

It is this film that is used for packaging batteries and storing batteries. You will be surprised, but polyethylene surrounds us everywhere.Blisters are made of it - plastic packaging for medicines. The film protects sterile medical products from moisture, foreign substances and microorganisms. Practically sealed containers keep bar soap, powders, and building dry mixes from dampness.

The packaging film is widely used in manufacturing to keep the goods from dust and dirt; as a covering material during repairs and construction works, for example, to protect windows from paint ingress.

Polyethylene is also suitable for thermal packaging, it is widely used in the food industry. Products acquire an additional gloss and look appetizing, and customers can see them from all sides without opening the package.

It is easier to paint on polyethylene. Depending on the components of the composition, the film may behave differently at certain temperatures. For example, today special covers for the remote control are produced, the material of such covers for heat shrinkage requires heating at lower temperatures than in production. Typically this temperature is reached by heating the film with a conventional hair dryer.

Species overview

The difference in the properties of the shrink film is explained not only by the thickness of the layer, but also by its composition. Special additives allow you to enhance or weaken certain characteristics, to give another useful quality. Depending on the additives, the packaging is divided into PVC, polyolefin and polyethylene. In this case, the thinnest samples start from 10 microns, and the densest and strongest ones reach 250 microns.

Pvc

Polyvinyl chloride film is convenient to work with: it does not require such a high temperature for heat shrinkage, and the process of reduction of polymer fibers continues until the final cooling, so the coating tightly wraps around the product. The film can be reduced by almost half.

After cooling, the polymer becomes resistant to temperature fluctuations and retains elasticity.

The PVC film perfectly retains the properties of the products packed in it. The significant advantages include a pleasant glossy shine of an absolutely transparent coating.

LDPE

High-pressure polyethylene is a little softer, but retains transparency and elasticity, for heat shrinkage it needs a temperature of + 120-200 ° C. At the same time, the shrinkage process occurs evenly throughout the polymer web. Main advantages: does not react with other chemicals, does not allow moisture and foreign odors to pass through. It has an average density of 40-180 microns.

Interesting that LDPE is often used to create anti-corrosion protection. At the same time, volatile corrosion inhibitors are added to the composition of the polymer web, which are released after the heat shrinking process. Thus, volatile compounds in a sealed space cover metal objects wrapped with a film and act as an additional protection against moisture ingress. At the same time, the inhibited film remains harmless to humans and does not change its properties.

POF

Polyolefin films have found their niche in the food industry. It does not contain impurities harmful to humans, it has the widest density range of 10-200 microns. At the same time, the canvas is elastic, resistant to stretching, mechanical damage, for example, from the corners of the box. Heat shrinkage starts from + 120 ° С, the material shrinks evenly on the goods, ensuring tightness.

Colored

Special additives give color to the polymer canvas. This is how you can get black polyethylene. However, in everyday life, colored shrink wrap is needed for other purposes. In industrial conditions, a picture is applied to the film - a color, a logo - by printing, and then the canvas is cut and sent to the necessary needs.

For example, this is an economical way to apply a picture to signs and decorations.The colored foil helps to protect individual elements from dirt and dust during construction work.

The most widespread use of such a polymer was found in the production of children's toys, printing products, and even the automotive industry. The density and strength of the colored film depends on the layer thickness, the color does not affect them.

Manufacturers

GOST 25951-83 regulates the requirements for finished products or the shrink film itself... This need arises because polyethylene is a product of the chemical industry, when working with it, you must follow the rules.

The polymer is supplied to the production of shrink film in a granular state. Further, on special equipment, the substance is heated until a homogeneous mass is obtained and a polymer web is formed using extrusion, it is given the necessary appearance, and laid according to the established rules. The final products are packaged in boxes and double-labeled. The outer marking is applied over the packaging, and the inner one is applied to a roll of film. It contains data such as the date of manufacture, the team number, and other data necessary for the identification and control of those responsible for production.

Film production is largely automated, but it has its own distinctive features, so it is more convenient for many manufacturers to be specialized: to produce specific products and services.

Special industrial exhibitions, for example, help to promote and acquire customers and contractors. RosUpack or TransPack (TRANSPACK).

Among the most famous manufacturers of shrink films are Russian companies and joint ventures. Known joint ventures in the Russian market:

- Russian-German "Südpak Rus" produces films, bags, packaging materials;

- CCL-Kontur manufactures self-adhesive labels and packaging for manufacturers of household chemicals, perfumery, pharmaceuticals, alcohol industry, food products;

- Japanese manufacturer FUTAMURA GROUP produces cellulose film for packaging small-sized products.

Russian manufacturers operate in almost all regions and often interact with industry institutions, introducing innovations and experimental production:

- TPK "Sahara" works with a wide range from packaging films to ready-made solutions for specialized industries;

- LLC "PROMTORGPAK" produces plastic wrap and bags, is engaged in processing and from recyclable materials;

- LLC "Vipak" produces multilayer film, which is in demand in the production of food and medical products;

- "VitaKhim" creates packaging for chemicals, raw materials and equipment;

- group of companies "RUSAN PLUS" produces packaging materials for dairy, bakery, confectionery, meat and fat and oil products;

- Don-Polymer produces PVC shrink film and packaging from it;

- LLC "Pakgrad" develops and manufactures food packaging.

Also noteworthy are the well-known companies TIKO-Plastic JSC, UNIPLASTIC shopping center, Packaging and Service trade division, Eximpak-Rotoprint LLC, Plastik DPO JSC, Kamsky polymer materials plant, PC TAURAS-PLAST LLC "And" Ecolin Ural ".

How to use?

In industrial conditions and volumes, shrink film can be used with the use of special equipment - machines that provide compression at high temperatures. Wherein You can pack a single item of different sizes, a group of items (the same size or different), or create a shape on special templates.

How to use such a machine correctly? The item to be packed is placed on a stand, wrapped in a film. Then the sections are closed with welded seams and the shrinkage procedure proceeds by moving the packed item into the heat chambers.

The packaging equipment itself is divided into automatic and semi-automatic machines by type. The machines carry out predetermined production cycles. Power and heating are selected according to the type of film, the size of the objects.

In addition to machine tools, to work with shrink wrap, you need a thermal knife... It heats up to a certain temperature, under the influence of which the web is cut evenly, without tears or damage.

If you follow the recommendations and use the equipment for heat shrinkage correctly, then the consumption of the film turns out to be economical.

The film for home use does not require serious equipment. Usually it is already prepared and divided into the necessary segments, it remains only to place an object inside the package and heat it. Shrink-wrapping manufacturers are looking for new safe home applications to expand their consumer base. The production of film is closely related to the search for new solutions, since any innovation helps to improve production, expand the scope of application and increase the profit.

For shrink wrap, see the video below.

The comment was sent successfully.