All About Thermal Transfer Film

Changing your image in order to stand out from others is quite simple - thermal transfer film, also known as flex film, will help in this difficult task. It is she who is used to apply various applications, images, inscriptions and stickers on a fabric or other surface. With the help of this unusual material, which will be discussed in the article, you can decorate any thing (from clothes to beautiful crafts or interior details), getting an expressive and vivid image.

What it is?

Thermal transfer film is a material made of PVC or polyurethane, on the surface of which some kind of image is applied, as well as an adhesive layer. As a rule, for this, manufacturers use a heat-resistant composition. Most often, film is used for printing iron-on applications on any fabric surface. The adhesive, being solid under normal conditions, melts at a certain temperature, firmly fixing the film on the base.

This technology differs from the process of sublimation when applying a pattern to fabric. Sublimation printing has a number of restrictions on the composition of the fabric, its type and color. Most often, white synthetic matter is used for sublimation.

At the same time, transfer films can be printed with sublimation inks, which will be applied through thermal transfer paper, as well as solvent-based inks.

There are also other advantages of the material:

- suitable for absolutely all types of fabrics, except for those treated with water-repellent silicone impregnations;

- versatility of use - it can be both simple clothes and special uniforms, bags, flags and much more;

- it is applied without much effort, it does not take a lot of time - a few seconds are enough;

- easily cut with a plotter, you can do this work in a home workshop;

- the film adheres perfectly to the material, does not lose brightness and clarity after washing, does not fade in the sun;

- when worn, this image wrinkles in the same way as the material itself, therefore it looks natural;

- a huge selection assumes the embodiment of any, even the most daring design idea.

The film is produced in rolls, with a thickness of about 60 microns. When transferring full color images or photographs to fabric, thermal transfer film is suitable for laser or inkjet printers.

In this case, the picture will turn out to be very bright and clear, it will last on a fabric base for a long time, even after many washes.

Varieties

Thermal transfer films for fabrics are classified according to various criteria.

By thickness

This is a rather serious indicator, and it is important to pay special attention to it, because thermal transfer film is, first of all, a sticker. Image quality will depend on its thickness. The thinner the film, the better the quality of the printed image. The thin shell adapts to each material and is easier to cut.

By composition

The composition of such film materials can be of 2 main types - it is either polyurethane or with a polyvinyl chloride base.

- Pvc - these are the most budget films, they are thicker and inelastic, have a more modest color palette, often they are not equipped with an adhesive backing. They are used on thick fabrics, for cutting and gluing larger parts, often such elements can be seen on overalls. Among the advantages, in addition to the low price, one can note a rather high washing temperature (80–90 ° С).

- Polyurethane (PU) Is the best thermal transfer. The material has a complex production technology, therefore, it also has a rather high price. It is thinner and more elastic. It is distinguished by its versatility: details, both the smallest, medium and large, are perfectly cut out of it. The transfer of images is better. Polyurethane, due to its low thickness, does not leave marks.

The material allows you to work with various types of fabrics, both natural and synthetics, mixed.

Flex films are quite diverse, they can be classified by color and texture.

- Standard color (these are absolutely all popular colors, however, the palette may differ from company to company).

- Fluorescent (neon colors) - neon orange is most often found, as well as pink, yellow, blue, green.

- Metallic - films can be painted in gold and silver.

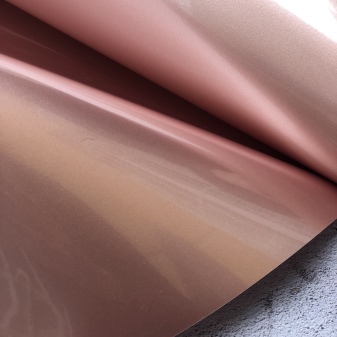

- Mirrored colors - these are glossy options for gilding and silver.

- With glitter - films of all possible shades, characterized by the presence of shiny glitter inclusions.

- Reflective flex. Reflective (aka retroreflective) film contains reflective elements, which in everyday life are called reflectors - this concept is used in colloquial speech. These are, first of all, light strips that distinguish special clothing, for example, traffic police officers, road workers. With its help, any equipment is marked, and it is also possible to use it for advertising and information purposes.

- Light-accumulating thermal film. This unique type of photoluminescent film accumulates energy during daylight hours, and then can glow in the dark for 6 to 8 hours. It is often used for the manufacture of identification marks, used in advertising products. Recently, T-shirts with such images have become fashionable - they are popular with the younger generation.

But that's not all - there are other types of thermal transfer films.

- Thermal films for so-called difficult fabrics, namely: siliconized, treated with water-repellent compounds. As already mentioned, simple thermal films cannot be glued to such a surface. But individual manufacturers have nevertheless developed quite unique products - their films are suitable for transferring designs to similar substrates.

- Films with high elasticity - such developments are used exclusively for delicate, stretchable stretch fabrics. This is a great option to transform your sportswear. The film does not deform even when stretched strongly while running or performing other exercises.

- Bulk thermal films. These products are capable of making a volumetric thermal transfer that will stand out above the surface of the material.

- Thermal transfer flock - an interesting and tactile material with a velvety surface. Products with this finish look exquisite. Fluffy letters or patterns will decorate many products. Flock is produced in a rich color palette. The material has an interesting feature - after the very first wash, the product will be even more attractive, as the villi will straighten out and become fluffier.

- Films with 3D effect occupy a separate niche. They help to create a three-dimensional image that is particularly authentic.

Manufacturers

In the market of thermal transfer films, a large number of companies are engaged in their release. Italian manufacturers, such as Siser, are considered leaders in the production of quality products. It is also worth noting the Korean company CE-301, as well as brands such as Chemica from France, German Poli-Tape, manufacturers from the USA - CAD-CUT.

Budget films are mainly made in the Middle Kingdom. It is believed that Chinese products are slightly worse than European and American ones. But in general, good products are produced in China. For example, we can cite the well-known company Econoflex on the domestic market.

How to choose?

When choosing flex films, it is important to consider a number of criteria.

Manufacturer

There is a rich assortment of thermal transfer films on the market today. Film from European (German, French and Italian) and American manufacturers is in particular demand. And this is not surprising, because they make quality products and supply them to all corners of the world.

However, for simpler work, as well as in order to save money, many use both Chinese and Korean products, which are also of good quality.

Film thickness

Flex films come in various thicknesses (within the range of 60–150 microns), so you should choose the one that suits your specific task. The most popular is considered to be a film thickness of 90-100 microns - such a product is suitable for a variety of jobs.

Adhesive layer

It is impossible to judge the quality of its adhesive layer solely by the appearance of the thermal film. At the same time, this parameter is one of the most important. There is only one way out: first, you can test a small sample of one or another version of the film. - this will allow you to make your choice and buy the required amount of material of decent quality. A high-quality adhesive layer differs in that the glue does not flow out of it at the time of application to the base, does not stain it, does not melt, while the film itself will be distributed evenly over the entire surface, and after cooling it will not come off.

The cost of thermal films also depends on the materials used. So, if you are faced with not very complicated work, as well as with a small budget, your choice is PVC film. If the jewelry execution of an intricate design or text with small letters is important, if you also need elasticity, wear resistance, a non-standard color for an unusual design, this is certainly a polyurethane film.

How to use?

Thermal transfer printing is not as difficult to work as it might seem to many. However, in the process it is worth adhering to certain rules. The first thing to do is cut out the selected picture or inscription... There is one nuance here - you need to cut it in mirror image. It is important that the image is transferred to the fabric correctly. For this operation, a plotter is used, after which the so-called selection is made: excess elements are removed - a clean picture (inscription or drawing) should remain, only what will be printed later. The selection can be done with a needle or a clerical knife, doing this very carefully.

After that, the thermal transfer film prepared in this way is placed on a backing on a T-shirt, for example. The image should be displayed horizontally in the same way as for sublimation. Then the film is exposed to high temperature. For this, a heat press is used, which heats up to 150 degrees and above.

Enough exposure for 15 seconds. This happens in professional workshops equipped with special presses. At home, an ordinary iron is enough for such a creative process as scrapbooking. The glue will melt and firmly adhere the image to the desired location on the garment. After completing this procedure, the backing must be carefully removed.

Some experts do re-burn. It is needed to "tightly" fix the thermal transfer film. It is important to take into account one more nuance - you can remove the substrate when it is cold, but it will be much easier to work with a warm one. At the same time, it is quite simple to distinguish warm from hot: touch it with your hand - if your hand tolerates the temperature, then you can shoot. That's all - you can proudly put on the product, wear it and stand out from the crowd.

At the same time, no physical impact will be terrible for a unique wardrobe item.

For information on how to write on the cover of a notebook using thermal transfer film, see the next video.

The comment was sent successfully.