How and how to glue the film?

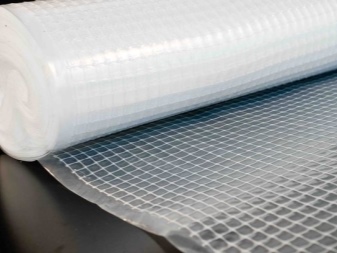

Polyethylene and polypropylene are polymeric materials that are used for industrial and domestic purposes. Situations arise when it is necessary to connect these materials or securely fix them on the surface of wood, concrete, glass or metal. Since polyethylene has a high degree of smoothness, it is rather difficult to glue such products together. To achieve good results, you can use various methods available even at home.

How to glue?

Polypropylene sheets, plastic, high and low pressure film cellophane - all these materials have a low adhesive ability. Their surface is not only smooth, but also has no porosity to absorb adhesives. To date, no special adhesives designed specifically for polyethylene have been invented.

But there are adhesives with a wider spectrum of action, which, under certain conditions, help to dock polymer materials.

Types of glue

Adhesives for polymeric materials are divided into 2 types.

- One-component adhesive - this composition is already completely ready for use and does not require any additional ingredients.

- Two-component adhesive - consists of an adhesive base and an additional component in the form of a polymerizing agent called a hardener. Before starting work, both components must be combined by mixing. The finished composition cannot be stored and is used immediately after preparation, since polymerization begins under the influence of oxygen.

According to the method of hardening, all adhesives are divided into 3 groups:

- cold polymerization - the glue hardens at a temperature of 20 ° C;

- thermoactive polymerization - for solidification, the adhesive composition or the surface of the material to be glued must be heated;

- mixed polymerization - the glue can harden under heating conditions or at room temperature.

Modern adhesives have additives that dissolve polymer surfaces, thereby creating conditions for better adhesion. The solvent tends to evaporate quickly, after which the polymer mass hardens, forming a seam. In the seam area, the surfaces of the two workpieces form a common web, so this process is called cold welding.

Top brands

The bulk of modern adhesives contains methacrylate, which is a two-component element, but without admixture of a primer-hardener harmful to the human body.

For gluing polyamide and polyethylene, adhesives of several popular brands can be used.

- Easy-Mix PE-PP - from the manufacturer Weicon. As a primer, crushed glass is used in the form of a fine dispersion, which, when distributed over the surface of the parts to be glued, ensures good adhesion. In the composition there are no impurities harmful to humans, so the product can be used at home. Before applying it to the working surfaces, they do not need to be specially prepared in any way - it is enough just to remove obvious dirt. The mixing of the components of the pasty glue occurs at the moment of its feeding from the tube directly to the gluing section.

- "BF-2" - Russian production. Has the appearance of a viscous substance of brownish-red color.The composition of the glue contains phenols and formaldehydes, which are classified as toxic substances. The adhesive composition is positioned as a moisture-resistant and versatile preparation intended for gluing polymer materials.

- BF-4 is a domestic product. It has the same composition as the BF-2 glue, as well as additional components that increase the elasticity of the seam. BF-4 glue is used for gluing polymers that are exposed to frequent deformation cycles and vibration loads. In addition, the adhesive can bond plexiglass, metal, wood and leather together.

- Griffon UNI-100 is a country of origin in the Netherlands. Consists of one component based on thixotropic substances. It is used to join polymer surfaces. Before work, such surfaces must be cleaned using the cleaner supplied with the adhesive.

- Contact is a Russian two-component product. Includes epoxy resin and hardener. Polymerization of the adhesive mass occurs at room temperature. The finished joint is highly resistant to water, gasoline and oils. The adhesive composition is used for polymer materials, as well as for gluing glass, porcelain, metal, wood. A thick mass of glue fills all voids and cracks, forming a single monolithic seam that does not have elasticity.

In addition to smooth polyethylene, foamed polymer materials also need gluing. The porous structure of foamed polymers is flexible, so the adhesive connection must be quite reliable. For gluing such materials, other types of glue are used.

- 88 Lux is a Russian product. One-component synthetic glue, which does not contain substances toxic to humans. The adhesive composition has a long polymerization period, the seam hardens completely only a day after gluing the surfaces. When using 88 Lux glue, the finished seam is resistant to moisture and sub-zero temperatures.

- "88 P-1" is a one-component glue made in Russia. The product is ready to use and consists of chloroprene rubber. The composition does not emit toxic components into the environment and is suitable for domestic use. After gluing, the resulting seam has a high degree of strength and flexural elasticity.

- Tangit - made in Germany. It can be produced as a one-component, ready-to-use formulation, as well as as a two-component kit. Two-component adhesive is considered more practical as it is suitable for bonding materials with a low degree of adhesion. The package includes a container with glue and a bottle of hardener.

The listed types of adhesives have an increased degree of adhesion, and the finished seam resulting from gluing has high reliability throughout the entire time of using the glued together polymer materials.

We glue the film at home

There are different situations when it becomes necessary to glue the polyethylene film. This can be preparing a greenhouse for the summer season or sheltering the rafters during roof repairs. Often, polyethylene is glued to perform production tasks or when performing construction work. The polyethylene film can be glued directly at the installation site, or the gluing is done in advance.

A process such as gluing depends on which surface you want to glue with a polymer material. The order of performance of work in each case will be different. Let's analyze the principles of gluing the film for various tasks.

Between themselves

You can glue 2 polyethylene sheets together with the use of BF-2 glue. The procedure is quite simple and can be done by hand at home. Before applying the adhesive, the bonding surfaces must be prepared.

- The surfaces in the bonding area are cleaned with a detergent solution in case of severe contamination. After cleaning, the film is wiped dry and degreased - this can be done with a solution of industrial alcohol or acetone.

- A thin layer of adhesive is evenly applied to the prepared surface. Glue "BF-2" tends to dry quickly, so both parts to be glued must be quickly combined with each other.

- After combining the two surfaces, it is necessary for the adhesive to completely polymerize and harden. To do this, he will need at least 24 hours. Only after the specified time, the glued product can be used.

A similar procedure for preparing the work surface and applying glue is used for other similar adhesives. In the process of performing work, it is necessary to observe precautions - use personal protective equipment and work in a well-ventilated area. When gluing large surfaces, for the convenience of performing work, a large volume of glue is used, placed in a cartridge.

It is most convenient to remove the glue from the cartridge using a special gun.

To metal

To adhere polyethylene to metal, do the following:

- the metal surface is cleaned with a metal brush, and then with coarse-grained sandpaper, then it is degreased with acetone or a solution of technical alcohol;

- the metal surface is carefully and evenly heated with a blowtorch to a temperature of 110-150 ° C;

- the plastic film is pressed against the heated metal and rolled with a rubber roller.

Tight pressing of the material ensures melting of the polymer, and after it cools down, good adhesion to a rough metal surface is obtained.

To concrete

Polypropylene in the form of insulation can also be glued to a concrete surface. For this you need:

- clean the concrete surface, level with putty, prime;

- apply the adhesive evenly to the other side of the polypropylene sheet where there is no foil layer;

- wait a little according to the instructions for the glue, when the glue soaks into the material;

- apply insulation to the concrete surface and press down well.

If necessary, the edges of the insulation are additionally coated with glue. After installation, the glue must be given time for polymerization and complete drying.

Other options

Using glue, polyethylene can be glued to paper or fixed to fabric. But, in addition to adhesives, you can glue the polymer material using an iron:

- polyethylene sheets are folded together;

- a sheet of foil or plain paper is applied on top;

- stepping back from the edge of 1 cm, a meter ruler is applied;

- with a hot iron along the free edge on the border with the ruler, several iron movements are carried out;

- the ruler and paper are removed, the resulting seam is allowed to cool completely at room temperature.

Under the action of a hot iron, the polyethylene melts, and a strong seam is formed. By the same principle, you can connect the film using a soldering iron. The difference is that instead of a hot iron, a heated soldering iron tip is drawn along the ruler. The result is a thin weld line.

You can also solder the polymer film with a fire flame. This will require:

- fold 2 pieces of film together;

- clamp the edges of the film into blocks of fire-resistant material;

- bring the material to the flame of a gas burner;

- tangentially draw the free edge of the plastic film over the flame, movements should be fast;

- remove the refractory bars, allow the seam to cool naturally.

As a result of welding, a strong seam is obtained, in appearance resembling a roller.

Recommendations

When performing the process of gluing or welding a polymer film or polypropylene, it is necessary to take into account the following nuances in work:

- the seam when welding polyethylene will be quite strong if it cools down gradually at room temperature;

- after gluing the polymeric material for the strength of the seam, it is necessary to give it additional time to complete the polymerization, as a rule, it is 4-5 hours;

- for gluing flexible polymeric materials, it is best to use glue that gives an elastic seam, epoxy resin in this case is not the most reliable option.

As practice shows, welding is the best and most reliable option for joining polyethylene sheets, while adhesives are most suitable for joining polypropylene.

For information on how to glue the greenhouse film, see the next video.

The comment was sent successfully.