All about reinforced polycarbonate

When constructing various structures, outbuildings at a summer cottage, including greenhouses, greenhouses, polycarbonate is often used. This material has a whole host of significant advantages. Currently, there is a considerable variety of different types of polycarbonate sheets. Today we will talk about the features and characteristics of the enhanced variety.

Features and characteristics

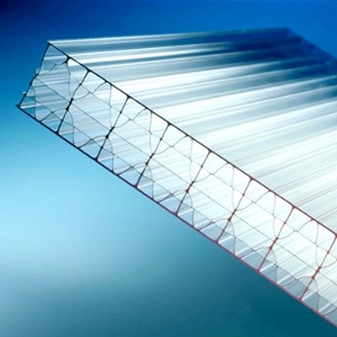

The reinforced version can be attributed to the premium polycarbonate group. It is made exclusively from high quality raw materials. As a result, the sheets are as strong and durable as possible. Reinforced polycarbonate is practically not exposed to mechanical stress, wind loads, atmospheric influences. In addition, the sheets have excellent heat-saving characteristics. The material has good sound insulation.

Such impact-resistant polycarbonate also differs from ordinary sheets in a much longer operating period.

The standard sizes of this material are:

- length 6 or 12 m;

- width 2.1 m;

- thickness from 0.8 to 3.2 cm.

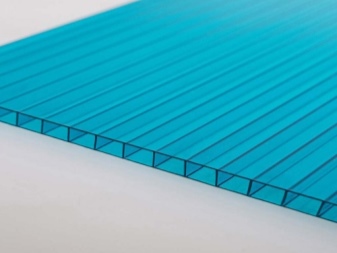

The material can be produced in a variety of colors, but most often you can find transparent models.

Comparison with other species

Compared to the standard, economy and other types of polycarbonate, the reinforced look has a higher level of strength, resistance to adverse external influences. Reinforced polycarbonate models can be covered with a special additional layer that will protect the panels from the harmful effects of ultraviolet radiation. It is formed using special thermoplastic boards. This protection prevents the sheets from darkening and tarnishing under the sun. Also, the difference lies in the fact that reinforced products have better light transmittance, noise insulation, and resistance to temperature extremes. These sheets are lighter and therefore easier to work with. They are available with a large number of rigid metal support ribs.

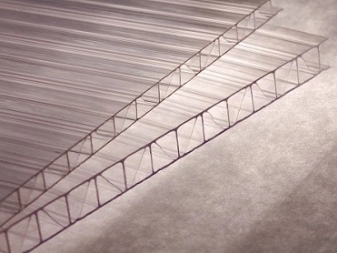

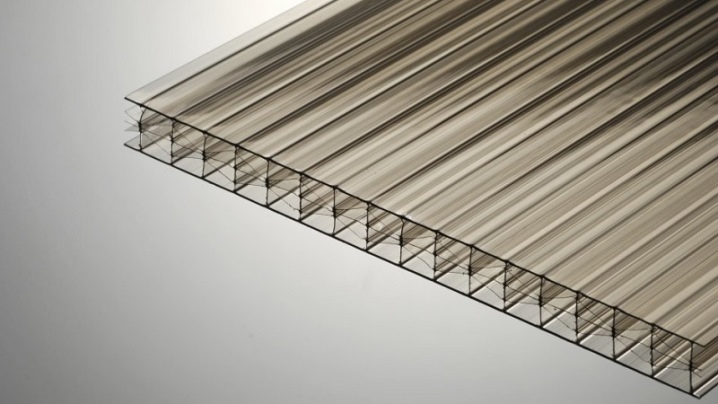

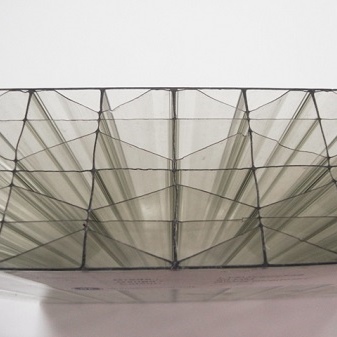

The difference between the reinforced version and the simple one lies in the improved characteristics of fire resistance. The material will not ignite when exposed to an open flame. The rate and degree of fusion will be minimal. It is worth noting that the price of such material is considered relatively low; it will be affordable for almost any buyer. Honeycomb reinforced material is often used in the construction of greenhouses and greenhouses in vegetable gardens. It has a more complex structure, several layers are interconnected with the help of special jumpers, it is they who will provide rigidity. This design allows you to create small voids between the layers, which increase the level of sound insulation and thermal insulation. Honeycomb sheets can have a different structure, it will be determined by the number of interconnected products. This type of polycarbonate has a special level of density.

What is reinforced polycarbonate?

Cellular reinforced polycarbonate can be of several varieties, depending on the type of structure.

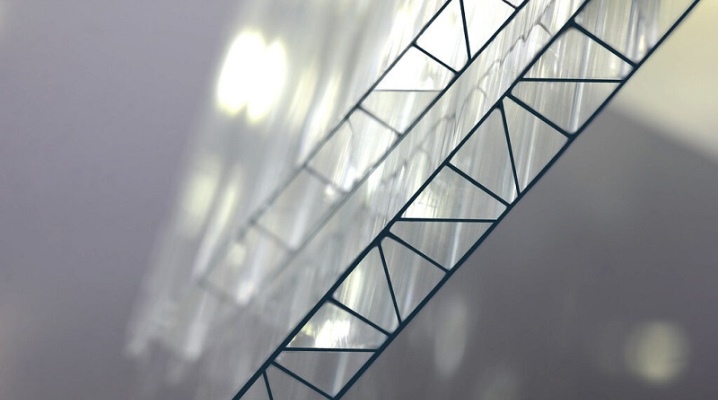

- 3RX. This structure includes 3 layers that are placed perpendicular to the stiffeners. The models also have additional partitions in the form of interconnected diagonals.This type of polycarbonate has a high level of rigidity, it can withstand stress with ease. Such panels are often used for floors with long spans when arranging clearcoats. Additional diagonals allow you to significantly increase the strength of the structure.

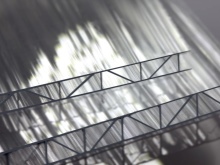

- 5RX. This structure includes 5 layers, they, as in the previous version, are located perpendicular to the stiffeners. The model has additional stiffeners for reinforcement. 5RX products are more often used in the arrangement of industrial buildings in which thermal insulation is important. In addition, they can be used as a material for creating façade wall panels.

The above varieties are the most common. But there are also some other species. A sample 9RX can be purchased if required. This eight-chamber model has the most reinforced structure. The thickness of such sheets varies from 1.6 to 2.5 cm.

Reinforced polycarbonate 6 RX model is also occasionally found. Such six-layer sheets are produced with additional rigid undulating partitions.

Applications

Reinforced polycarbonate is currently quite widely used in the construction of various structures.

- So, sheets thick 4 mm often taken when creating store windows and canopies, greenhouses.

- Structures with thickness 8 mm can be suitable for the production of industrial greenhouses and for the formation of roofing.

- With vertical glazing, it is better to purchase material from 10 mm.

- For any horizontal and inclined structures, you should buy sheets with a thickness not less than 16 mm.

- The most durable and stable models from 20 mm used in the construction of balcony structures, winter gardens, swimming pools, industrial facilities.

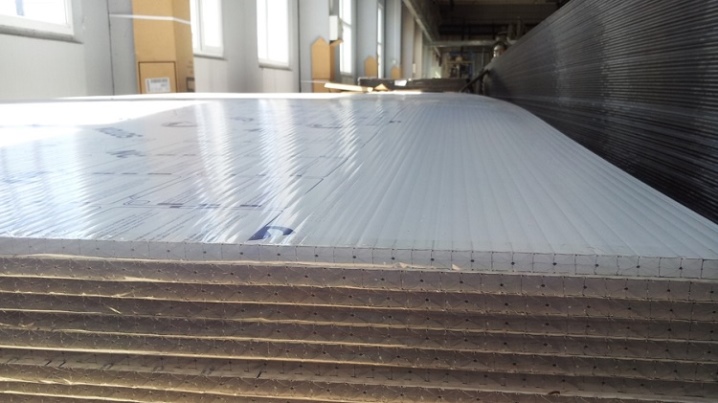

Transport and storage

Reinforced polycarbonate is considered an unpretentious material, but some important rules for transportation and storage should still be followed. Such sheets can be transported only in a horizontal position, while it is better to fasten them together in advance. If you plan to store polycarbonate outdoors, then it is better to cover it with polyethylene material. On such sheets, you should not place other objects and construction devices that can quickly heat up. It is best to store this material indoors with the lowest possible humidity level.

The comment was sent successfully.