Should film be removed from polycarbonate and how to do it?

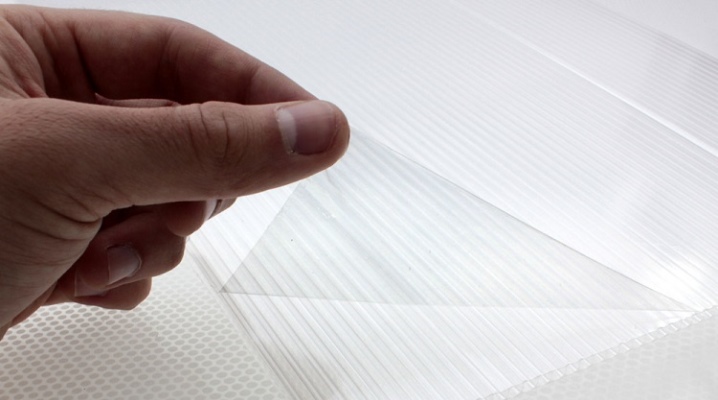

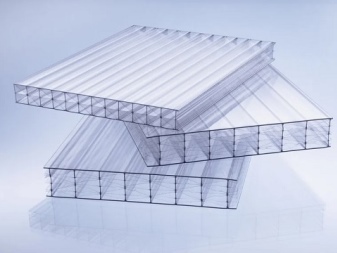

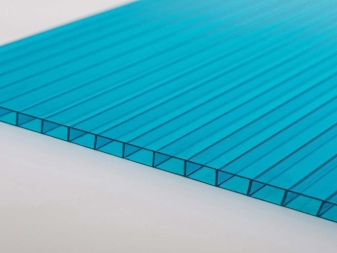

Polycarbonate is a thermoplastic polymer that is often used in the construction of gazebos, balconies, awnings, greenhouses and other windproof, translucent and shock-resistant structures. Due to its versatility, it is widely used in various fields. During the installation of the polycarbonate sheet, it is important not to forget to remove the protective film from the surface.

Sometimes builders simply do not remove it, and subsequently it adheres firmly to the smooth material. It is quite difficult to remove the film later, because carelessness can lead to scratches and other damage to the polycarbonate canvas.

The need to withdraw

The nature of polycarbonate is such that it is unstable to ultraviolet radiation, therefore, for a durable service of polycarbonate sheets in production, a protective layer is applied to them. Also, special impurities are added to the polymer mass. A special film is applied to all sheets to prevent damage to the material during transportation, unloading and installation.

On the outside of the polycarbonate sheet on the film, the brand, warranty period, manufacturer and information regarding sun protection are standardly indicated. The film is colored and often even with some kind of drawings. On the inner side of the canvas, as a rule, the film is completely transparent. It also needs to be removed for better light transmission of the material.

The film must be removed from the polycarbonate in a timely manner, otherwise in a year it will spoil the appearance of the structure.

It is recommended to remove the protective coating from both sides of the plastic sheet at the end of all installation work. If you leave it, then over time from exposure to solar heat, it "sticks" to the polycarbonate. In the future, getting rid of the film will be quite problematic. Especially often a similar situation can be observed when the structure with polycarbonate was assembled in the summer, and the protective layer was not removed in time.

If you do not remove the protective coating from the outside of the cellular thermoplastic, the dark areas of the pattern will simply be soldered to the polycarbonate surface. Over time, the film will take on an ugly look and turn into rags, it will be very difficult to remove it.

In winter, the film left behind will become an obstacle to snow, since without it the accumulated snow would slide off the polycarbonate surface much more easily.

It is important to determine in advance where the front side of the polycarbonate is. This is not very difficult given that the films always differ in color. In this case, the film can be applied and marked in different ways.

- The transparent film is glued on both sides - the canvas is completely protected from the destructive effects of ultraviolet rays.

- One-sided foil application with markings on the back. Determining which side of the polycarbonate is outer is quite simple - the sheet is laid with the marked side up.

How to quickly remove the film?

What to do if you forgot to remove the protective coating in time, and it is firmly stuck to the polycarbonate? There are several ways to solve this problem. Which of them to apply is to be determined independently, according to a specific situation.

If the sheets of polymer plastic have been in the sun for a long time, and the coating has baked to their surface, it is undesirable to do something. There is no need to shoot it, because in just a season the outer film will go away on its own. It will take more time to self-destruct the coating from the inside. It is unacceptable to scrape and peel off the polycarbonate film - this will only aggravate the situation and lead to damage to the material. Even nails cannot be used for this purpose. The risk of leaving marks on the canvas remains high.

Correctly remove the film from the cellular polycarbonate, starting from the edge to the center, carefully and slowly. If you scrape off the special coating from the UV protective side, it is easy to ruin the UV protection. It is quite simple to determine on which side this protection is located: inscriptions or some kind of service pictograms are always applied to this side.

It is not recommended to heat the film layer (some consumers try to heat it with a hair dryer), otherwise it will stick much more.

On the seamy side of the canvas, the coating is completely transparent. It also needs to be removed. If the inner film layer is left intact, the coating will deteriorate over time, which negatively affects the appearance of the structure.

The following method will help to remove the film: the surface of the polycarbonate canvas moisten with hot water diluted with any available dishwashing detergent. After a few minutes, when the film is soaked, you can try to remove the protective layer. A soft foam sponge is suitable for this. Tear off the film protection slowly.

You can try to remove the protective film with a solvent... The best way to cope with this task is "White Spirit", which is offered at an affordable price in every building store. This solvent does not have a detrimental effect on the structure of the polymer thermoplastic, but has a destructive effect on the adhesive film and promotes its detachment from the web.... After applying the solvent, you must carefully pull the film at any of the corners, carefully removing the coating from the surface of the plastic material. In this case, the use of metal or wooden objects is strictly prohibited in order to avoid damage to the transparent polycarbonate.

It is noteworthy that sometimes the film "stuck" under the sun can be torn off without aids, if you wait until it peels off on its own. This often happens during the long-term operation of a polycarbonate structure.

Potential uninstallation problems

The broken integrity of the UV protective layer can adversely affect the translucency of the sheet, which in the future will lead to clouding of the surface and subsequent cracking. After scratches appear, cracks may occur on the material. Therefore, it will last much less than it should be and will lose its visual characteristics.

If the film is stuck to the plastic sheet, any heating devices that have a similar effect are not suitable for removing it. Special attention should be paid to this requirement for craftsmen who decide to remove the dried film using a building hair dryer. The use of heating devices promotes the adhesion of materials, due to which the film sticks even more strongly, and then it will be unrealistic to remove it. The polycarbonate sheet, to which the film has adhered, will look bad, and it is no longer possible to restore it in the future.

For information on how to properly remove the film from monolithic polycarbonate, see the next video.

The comment was sent successfully.