Description of profiles for polycarbonate and their varieties

Cellular polycarbonate is a very popular building material; products made from it are strong and durable. But it is worth mentioning additional elements - profiles for carbonate connection. Their choice depends on the characteristics and features of the building.

Features and purpose

The modern market is represented by the most diverse assortment of fasteners for polycarbonate sheets, options can be selected both in size and type of structure, and in color preferences. Polycarbonate profiles are additional materials that are made from aluminum or polycarbonate composition. They are necessary in order to mount any structure, give it an aesthetic and finished appearance and increase its service life.

Thanks to the add-ons, the installation is easier and faster.

Species overview

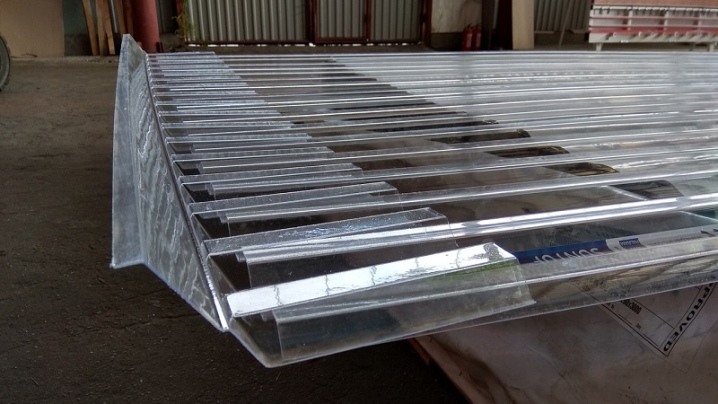

The polycarbonate profile is used to connect the fabrics of the material to each other. The process itself can take place along the side or along the cut. The connecting profile is divided into the following types: for honeycomb carbonate, for monolithic carbonate, one-piece, split. Most often, profiles are used for the construction of greenhouse and arched structures. According to their purpose, they are subdivided as follows.

End

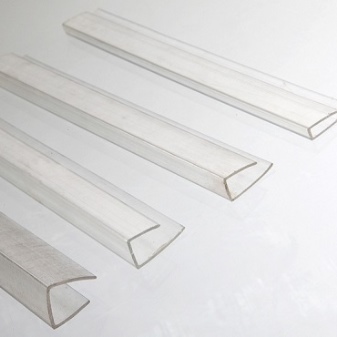

This look is designed to protect the edge of the polycarbonate and reinforce the entire building. For monolithic canvases, it is not necessary to use the end strip, here it is more represented as a decor. Water (melt or rain), dirt, dust or insects can get inside the unprotected material. At negative temperatures, the water that gets into the honeycomb freezes, which leads to deformation or destruction of the web. All this can spoil the appearance. The end or starter mount is a U-shaped bar, one edge of which is shorter than the other. The sides of the profile are made so that they are slightly curved inward - this is necessary for a tight connection of the polycarbonate with the bar.

Advantages of plastic accessories: relatively low weight, elasticity, durability and reliability, easy installation, which even an inexperienced person can handle. End strips are marked as follows: U, UP or PT. Unlike plastic, aluminum profiles are more expensive, but the structure installed with a metal frame has a longer service life - from 10 years and more. Mainly used for thick polycarbonate - 16 mm, 20 mm, 25 mm, 32 mm. The aluminum end profile also has a U-shape, where both sides are symmetrical. Advantages of this material: strength, corrosion resistance and long service life. Additionally, a decorative or protective film can be applied to the metal.

Connecting strips

When assembling the structure, polycarbonate sheets are not mounted immediately on the frame, first they are inserted into the grooves of the profiles. Such a docking bar is not a load-bearing element; it holds the carbonate sheets together, protecting the entire structure from leaks and ensuring its integrity.

There are two types of connector strips.

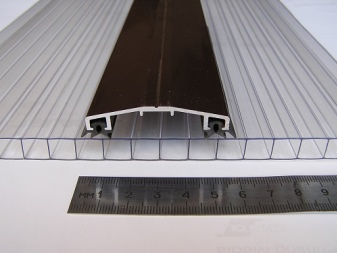

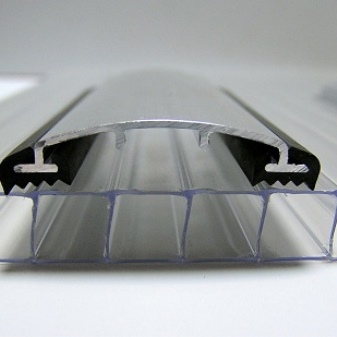

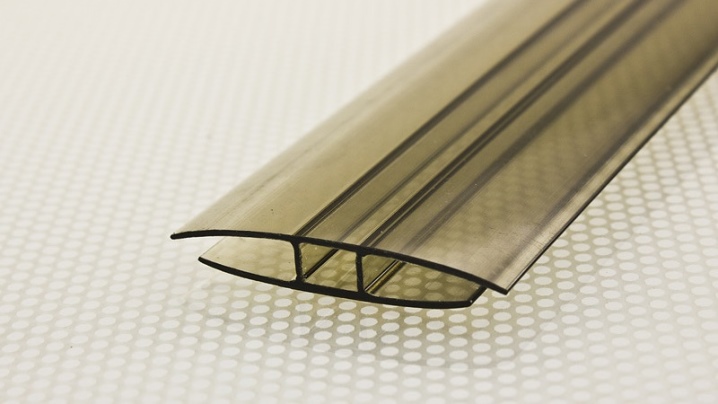

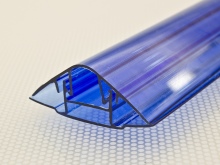

- Non-detachable - such profiles are made of polypropylene (plastic). They are used for sealing material joints with a thickness of 4-16 mm, in straight or curved structures. Installation of a one-piece profile requires accuracy and skill - the connected canvases must be correctly installed in the "pockets" of the strip.The small thickness of the plank allows you to create an almost invisible joint without waves, bumps and other deformations. It is marked as follows: PN (one-piece docking polycarbonate profile) and PSN (H-shaped connecting profile). The sides of the plank have a slight bend towards the inner side for better adhesion to the polycarbonate sheets.

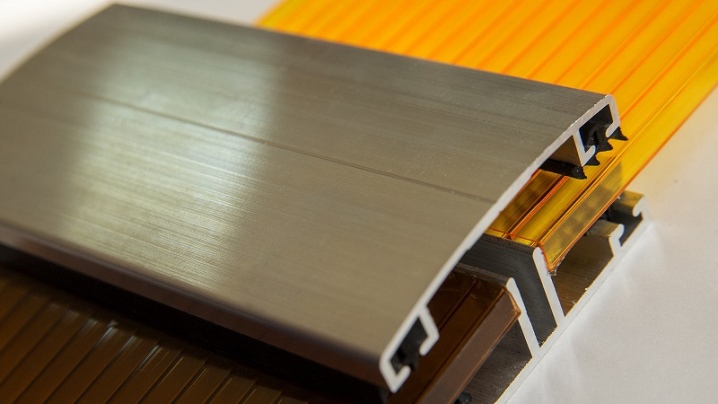

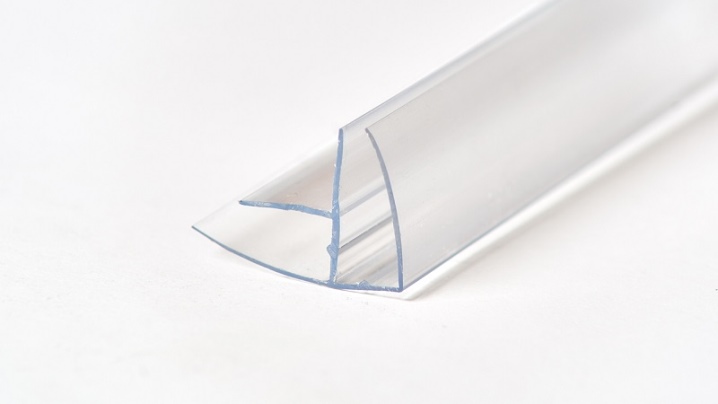

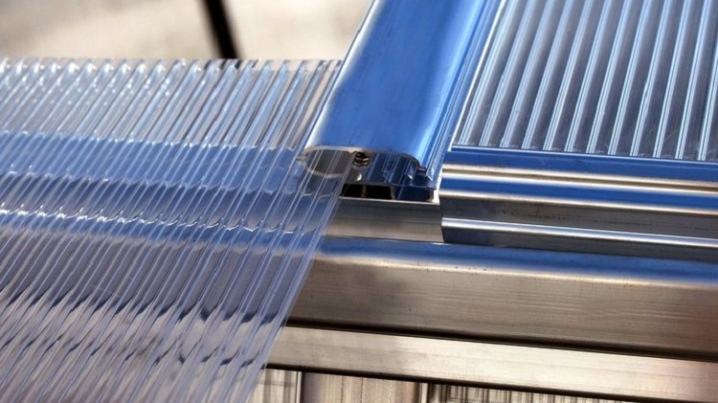

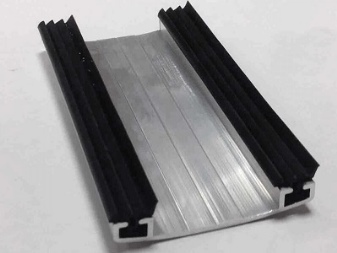

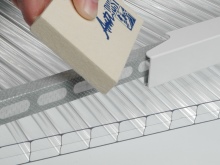

- Split ones are usually made of plastic or aluminum. The system has two components - a base-base and a lid with a special configuration. The parts are fixed to each other using a special connection - a lock. The base-base has a D-shape, is mounted to the frame, after which a carbonate sheet is installed and closed with a profile cover. When working with a split strip, do not apply much force, otherwise the connection lock may be damaged or destroyed. Has the following markings: PSR or connecting D-shaped profile.

The docking strip made of aluminum can take up part of the load-bearing load of the frame.

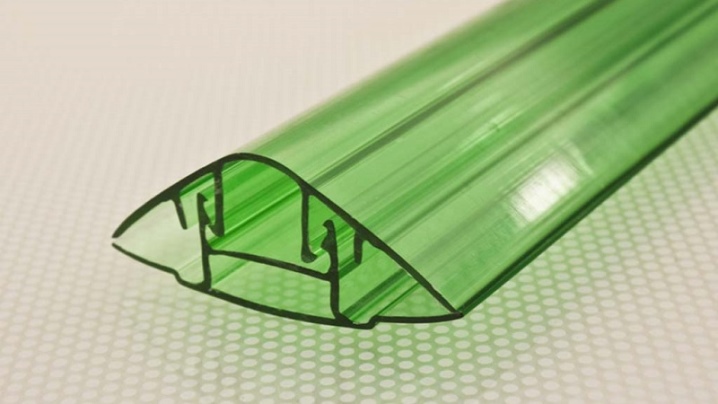

Skates

With the help of a ridge profile, polycarbonate canvases are connected at different angles, but not less than 30 ° (to create gable roofs, for office partitions). It is necessary to insert sheets of carbonate into the grooves of the profile until it is fixed to the structure - this is done for convenience and ease of installation. Additional mounts for skates are not required, but for reliability it can be fixed from the inside with small screws. The length of the ridge fastener is 6 m, for transportation it is twisted. Marked as RP.

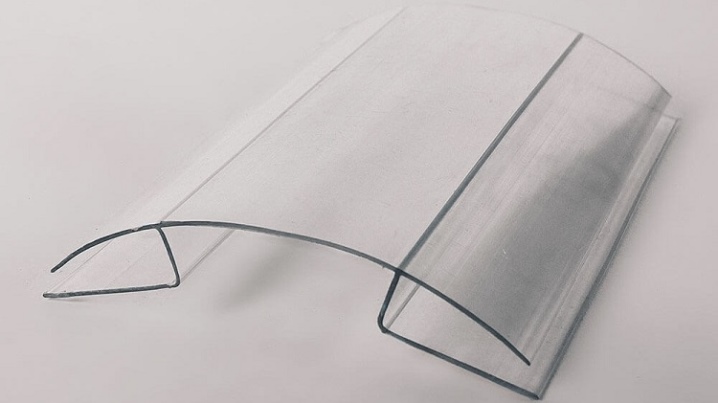

Corner connections

Angle fasteners are used to mount carbonate canvases at an angle of 90 °. The size of the plank is 6 m. Also, the corner joints serve as a decoration - they close the cuts at the joints. The main difference from other fasteners is the resistance to twisting and increased rigidity. Profile marking - FR.

Wall profile

This type of fastener is used for mounting a roof with walls. The connection can be made with wood, metal and monolithic surfaces. Also, the wall attachment can perform the functions of end fasteners. One side of the plank is equipped with a special groove for the carbonate sheet. Marking - FP.

Sliding

The profile is intended for systems with polycarbonate panels, where the carriages for movement are installed on the canvas. Used for carbonate with a thickness of 8-12 mm. The mount can be of two types: clamping and point-clamping. The first ones work according to the following principle: the strips clamp the canvas on both sides from the ends, the grooves are superimposed on top of the sheet, and the clamping screw must be on top. In such a fastener, an end fastener made of aluminum is superimposed on top of polycarbonate.

For point-clamping, it is necessary to fasten the grooves to the polycarbonate by means of a clamping screw that will pass through the sheet of material. The mechanism can only be with the top slide of the open, closed or hinged type.

Perforated tapes

In order to naturally remove condensation from the honeycomb carbonate, to prevent dirt or insects from entering the cells, self-adhesive perforated tapes are used. They are made from non-woven materials that have undergone special processing. They are glued to the lower end of the material.

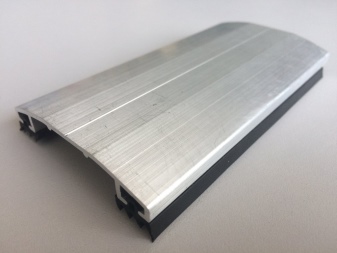

Clamping bar

It is used for installation of canvases to the frame, consists of an aluminum strip and rubber seals. Sometimes craftsmen use it instead of connecting fasteners.

Materials (edit)

Polycarbonate profiles are made from plastic and metal. PVC fasteners are more popular due to their flexibility, durability and variety of colors. For the manufacture of metal profiles, aluminum is used, such profiles are more rigid, they increase the bearing capacity of the entire structure. They are almost always equipped with rubber seals.

In addition to profiles, it is necessary to be able to correctly select additional materials and accessories that increase reliability and make the structure the most durable. Thermal washers - point-type fasteners for all types of polycarbonate.

It has three components: a washer with a stop (reduces the risk of overtightening to a minimum), an O-ring (serves for sealing), a plug (a decorative element that covers a self-tapping screw).

Polycarbonate thermal washers have a number of advantages over simple polypropylene fasteners: transparency and shade are combined with a carbonate sheet, increased service life and increased strength, the ratio of the coefficient of expansion due to heat is similar to the expansion of the sheets. Thermal washers polypropylene have less durability, shorter service life, opaque. But due to their low cost, they are very popular.

Thermal washers made of metal are made of stainless steel. They are used for monolithic polycarbonate. The package includes a rubber seal, which is used to ensure the reliability of fixation and the tightness of the fastening. Aluminum tape is a material used during bonding of carbonate sheets. It provides complete isolation and sealing of the sections and joints.

Installation features

In order for the junction of the profile and the canvas to be reliable and durable, the edges of the polycarbonate must be cut off. The base of the connecting strip must be fixed to the frame with special screws, the distance between which is 30-40cm. Aluminum profiles minimize the use of load-bearing structures due to their rigidity. For polycarbonate 8 mm, the width of the sheet is 60 cm, for 10-16 mm, the width of the web is 70 cm.The distance between the bearing components can be from 6 to 8 m.

The ends of polycarbonate in a vertical or inclined structure are closed with perforated tape from the top side. In arch-type buildings, the tape must be attached on both sides.

End profiles do not require additional fixation with glue, self-tapping screws, etc.

For information on how to attach the polycarbonate connecting profile to the arch, see the next video.

The comment was sent successfully.