What does the density of polycarbonate affect and how to find it out?

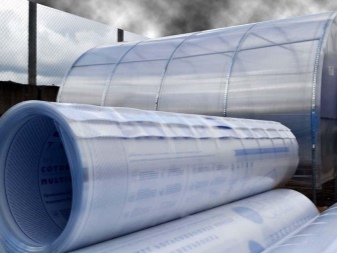

Polycarbonate greenhouses are very popular among summer residents and owners of suburban areas. In addition, this material can be used to create terraces, pavilions, canopies and verandas. When choosing a suitable type of polycarbonate, its density should be taken into account so that the structure turns out to be strong and durable.

What does it mean?

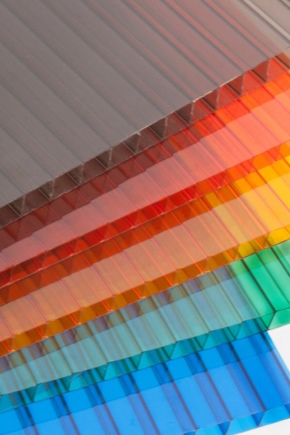

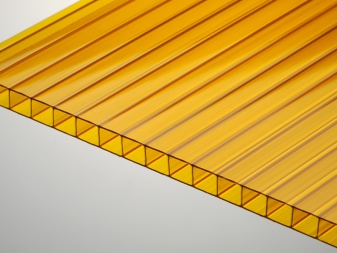

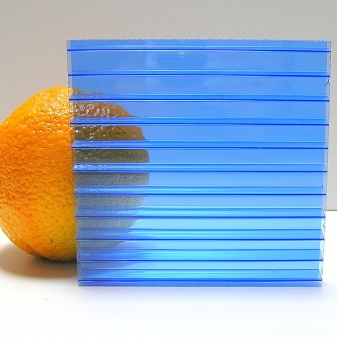

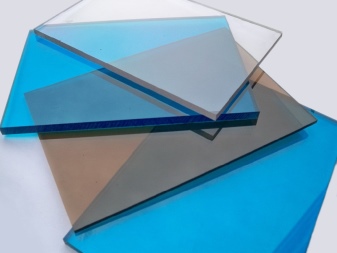

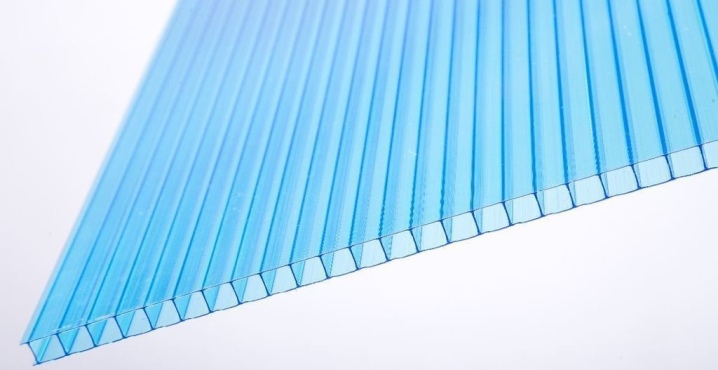

Polycarbonate is a modern material made of polycarbonate granules, which can be honeycomb and monolithic. Such a material transmits sunlight, like glass, but has greater strength and durability. In addition, it retains heat well, has good flexibility and is less weight.

When choosing such a translucent material for greenhouses or other structures, the density of the polycarbonate should be taken into account. This is an important technical characteristic that describes the ratio of weight to volume, which is indicated as kg per m3.

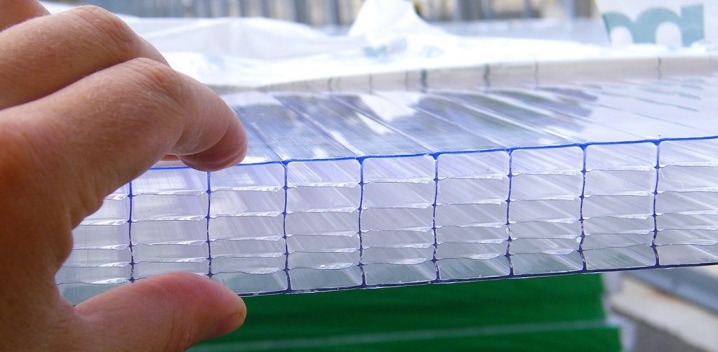

This is an important indicator that may differ not only for monolithic and cellular polycarbonate, but also for sheets of the same type and of the same thickness. The weight of one cubic meter of material varies from 0.52 to 0.72 kg. In a lightweight polycarbonate honeycomb sheet, the thickness of the walls and internal stiffeners may differ, which affects its strength.

The thinner the inner partitions of the honeycomb, the less the strength and impact resistance of such a material. If greenhouses or other structures are assembled from such polycarbonate, they should be regularly cleaned of snow in winter, otherwise they will simply break under its weight.

Lightweight polycarbonate with thin internal partitions is cheaper, since its shelf life is 3-4 years less than that of polycarbonate with a higher density.

What depends on the density?

This is an important material characteristic that affects the quality of polycarbonate:

- mass;

- features of the internal structure;

- volume and thickness;

- its transparency and ability to transmit sunlight;

- sheet weight.

The density value ultimately determines the performance characteristics of polycarbonate and affects the conditions under which such material can be used, its resistance to such external factors as:

- temperature regime;

- wind;

- exposure to sunlight;

- hail;

- snow.

The higher the density of polycarbonate, the longer its service life and the higher its resistance to negative factors.

It should be borne in mind that high density values of such a material significantly reduces its transparency, which makes it impossible to use it for growing vegetables and other cultivated plants in greenhouses.

The density of a material is directly related to its weight. When choosing polycarbonate for a specific type of structure, you should correctly calculate the strength of the metal structures from which the frame will be assembled. Otherwise, metal structures may not be able to withstand the weight of too dense and heavy material made of polycarbonate capsules.

Standards

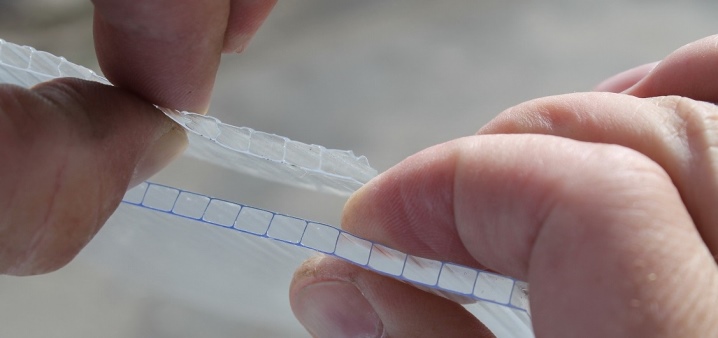

When choosing a suitable polycarbonate, this parameter can be determined by eye only on a monolithic sheet. For cellular polycarbonate, the optimal density is selected according to special standards, which, with different indicators, can have the same thickness.

Monolithic polycarbonate has an average density of 1.18-12 g per cubic millimeter. When using monolithic sheets, small differences in the density of the material do not affect the strength of the structure being erected. Monolithic polycarbonate is used in the manufacture of interior and office partitions.

In a cellular analog, the density is more varied and differs greatly in values. When choosing lightweight sheets, you should use a special standard table, which indicates for what purposes cellular polycarbonate of a certain density can be used.

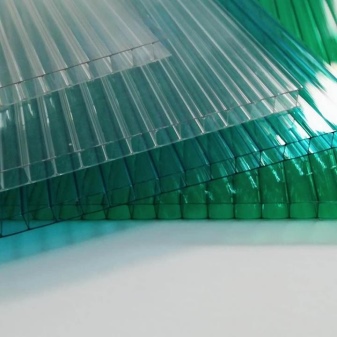

For greenhouses and lightweight structures, it is recommended to use sheets of low density, 4-6 mm thick. In this case, it is possible to maintain the optimal ratio of strength and thickness of the sheets.

Sheets with a high density of 0.72 g / m In this case the difference in density and weight requires the use of more durable metal structures as a frame that can withstand the weight of such polycarbonate.

The most durable and dense is considered to be a luxury polycarbonate sheet, capable of holding bullets and withstanding the impact of small-caliber projectiles. Shields for special services are made of such high-strength material.

How to determine?

You can find out the density upon purchase by examining the labeling of the sheet. The manufacturer always indicates this characteristic of polycarbonate in the marking. In order to choose the right material of the required density, you can ask the seller to calculate not only the number of sheets, but also this characteristic for a particular design.

You can check the density at the time of purchase with a simple compression test. The higher this indicator, the more difficult it is to squeeze a sheet of cellular polycarbonate with your hands.

Denser analogs from less dense and durable ones can be distinguished by price.

High-quality and durable cellular polycarbonate, designed for a long service life, belongs to the middle and luxury price segment. Sheets with a maximum density of 0.82 g / m³, the thickness of which is measured in millimeters, cannot cost less than 1000 rubles.

It is very difficult for a visually inexperienced person to distinguish sheets with different densities. Therefore, you should always turn to the services of trusted manufacturers who sell their products in a wide range. Such companies will help you to choose the right density of cellular or monolithic polycarbonate, which is measured in standard terms (grams per cubic millimeter).

Which sheets to choose?

The choice of polycarbonate of suitable density depends on the purpose of the structure for which such a material is chosen. For greenhouses and winter gardens, it is better to choose cellular polycarbonate with a density of 0.4 to 0.6 g / mm3. Such material transmits sunlight better and has acceptable strength.

The design of the greenhouse, which has a sloping shape, does not allow snow to linger on the surface of such a structure in winter, which makes it possible to reduce the load on the sheets of medium density and avoid their destruction under the weight of snow.

For awnings, pavilions, glazed terraces, verandas or interior partitions, it is better to use high density polycarbonate, which allows less light to pass through. If you order such material from a well-known manufacturer or an official representative, then you can get free advice and calculations when choosing sheets of optimal density for certain needs.

For non-collapsible structures that are used throughout the year, medium to high density sheets are needed. For collapsible structures that are used only in the summer, and for the winter they are disassembled and stored assembled, cellular polycarbonate with a lower density, which is cheaper, is suitable.

The comment was sent successfully.