Overview of accessories for polycarbonate

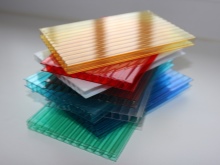

The correct choice of component parts for working with polycarbonate will determine the duration of operation, strength and moisture resistance of the created structure. Sheets made of such a material, when the temperature values change, narrow or expand, and the elements that complement them should have the same properties. Standard fittings are made on the basis of aluminum or plastic.

Profile overview

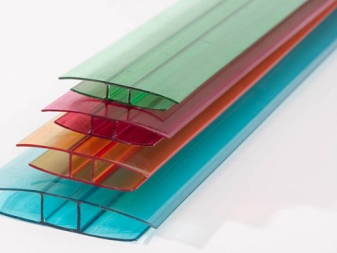

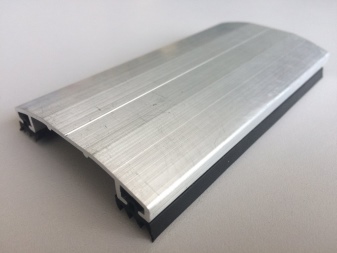

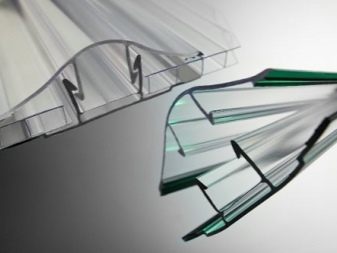

Profiles are addons, which are created from a pre-prepared polycarbonate mass. Aluminum alloys are an alternative for it. Such accessories for installation are simply irreplaceable, as they ensure the durability of the finished object, aesthetics. Work on the arrangement of polycarbonate is simplified and accelerated when using profile systems.

The modern market offers a large selection of accessories for fixing sheets. The options for the required configuration, thickness, color are easily selected. There is a huge assortment of profiles, among which you can choose the one that is suitable for a particular case.

Customized profiles are much easier to work with, so don't buy them at random.

End-type profiles (U-shaped or UP-profil) create excellent sealing in the places of end cuts. Structurally, it is a U-shaped rail containing a chute for quick drainage of condensate. Fastening is carried out according to the principle of attaching the device to the sheet from the end side. So moisture, all kinds of pollution do not enter the cavity. Before this, the end zone is closed with a special tape based on polyethylene, fabric or aluminum.

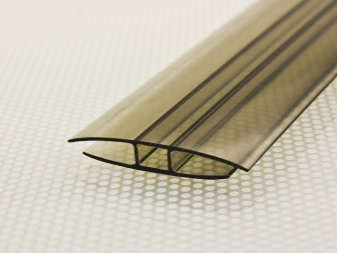

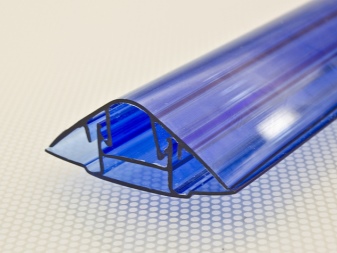

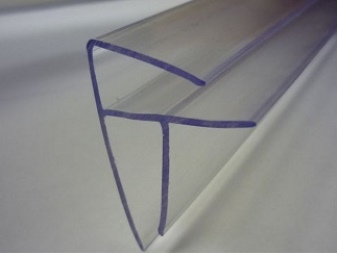

Connecting HP-profiles of one-piece type are made in the form of a rail. They are components for monolithic or honeycomb carbonate. With their help, arched, flat structures are created, with the correct joining of individual sheets. At the places of their connection, atmospheric moisture does not enter. It is unacceptable to use such devices as fasteners for fixing the canvas on the frame. Its direct purpose is to remove dirt and water after precipitation, condensate drainage, and it also gives a complete look to any structure.

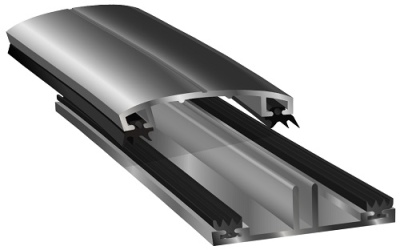

Another type of connecting profiles, but detachable - HCP. They are structurally represented by a cover and a base part. When using such products, installation is greatly simplified, and even inexperienced people can cope with the work. Such a connecting element is necessary when laying plastic on a frame base. With its help, a reliable joining of the canvases is organized, the work is done very quickly. The detachable part is firmly fixed with the lower part on the carrier substrate, its upper zone is snapped into place during installation.

The ridge RP-connector is used in relation to monolithic or honeycomb web, when work is done at any angle. The latter can change rapidly during installation work. Structurally, such an element is represented by two end extensions that connect a flexible joint that changes the mating angle. The ridge is subject to strong sealing, while maintaining the aesthetic component.

Angle type FR profiles are used when joining monolithic or structural material. Their peculiarity lies in the connection of two parts with observance of an angle of 60, 45, 90, 120 degrees, depending on the configuration of the object.Compared to other plastic panels, the corner pieces exhibit increased rigidity and resistance to twisting during operation. Purpose - to ensure tightness in the corner joints of polycarbonate.

There are wall profiles of the FP type. They are required to create the most airtight joining of polycarbonate sheets to the walls. Providing at the same time the function of the adjoining addition and the end unit, such products are mounted on a monolithic, metal, wooden base. Installers in their work often call such products as starting products.

The profile system on one side is equipped with a special groove, in which the end part of the roofing sheet is securely fixed.

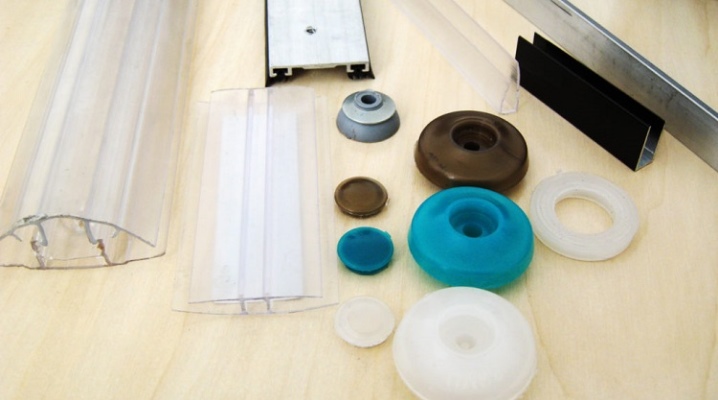

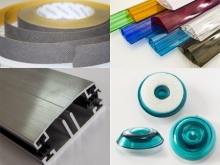

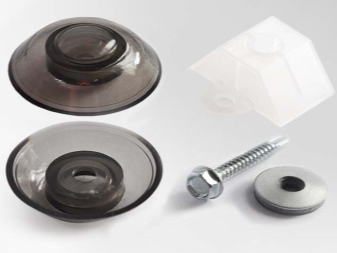

Thermal washers

Such devices are required to fix the panels directly to the frame base. With their help, thermal expansion is compensated in case of strong cooling or heating of the polycarbonate sheet. Structurally, they are represented by a lid, a silicone gasket, a washer with a leg. Most often, there are no self-tapping screws in the configuration, they are selected separately, taking into account the required size.

Today, leading manufacturers increasingly do not apply leg washers to thermal washers. This is how the maximum convenience is set, since for the installation of such a washer it was previously necessary to create holes in the canvas 14-16 mm or more in depth. For washers without legs, the recess does not exceed 10 mm.

Other components

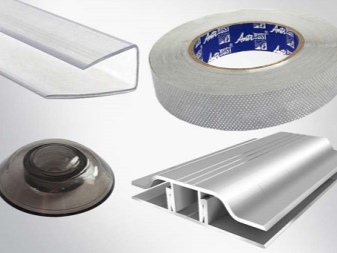

The fittings that complement the polycarbonate during its installation create a strong connection and fastening of individual sheets to each other, sealing the joint zones. Many of the complementary accessories are presented in several variations. This greatly simplifies the selection of the necessary products for a specific color of the installed canvases, taking into account their design features, requirements for external finishing. Most of the fittings are fixed with special locks or self-tapping screws. In this situation, it is important to carry out the installation using hardware.

It is important to point out that the main characteristic, under which all accessories are united, is increased flexibility, coupled with plasticity and reliability. At the same time, excellent strength is manifested even with a sharp change in temperature. They are resistant to solar radiation and moisture.

All additional accessories are presented in several positions.

- Guides for polycarbonate sheets, these include the above-mentioned profiles of all variations. The direct purpose is represented by joining the panels with each other, with additional surfaces or materials with the provision of protection for the end zones and corners.

- Reliable sealing materials (for example, U-shaped rubber seal) refer to fittings that are mounted on polycarbonate. They are made with AH type seals, perforated or end strips. They are used to ensure the protection of the canvases from external moisture, mud accumulations. Such accessories also create additional fixation of the used guides.

- Fasteners are presented, in addition to thermal washers, also clamping strips, adhesives intended for polyurethane resins, self-tapping screws for the roof. End caps are equally important.

Before starting the installation work of polycarbonate, you must purchase the required accessories. They are selected in accordance with the characteristics and characteristics of the base material.

Watch a video on the topic.

The comment was sent successfully.