Everything you need to know about solid polycarbonate

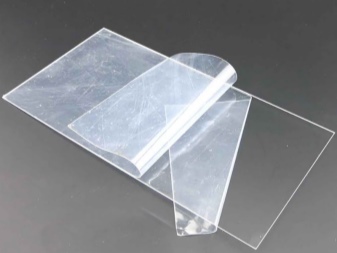

Monolithic polycarbonate is a material with different colors and textures of sheets, which is widely demanded in the field of construction and design. It is distinguished by its simple installation, impressive performance, and the feedback on the use of such modules looks very attractive. It is worth talking in more detail about where exactly cast transparent and colored sheet polycarbonate can be used, how it happens, how it differs from cellular.

What it is?

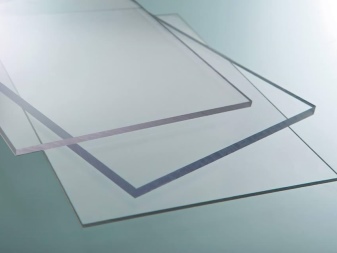

Monolithic or cast polycarbonate sheet is a polymer-based material. It looks like an acrylic coating, has a transparency similar to glass, and can be painted in various shades. The production of products is carried out using the extrusion or casting method.

Monolithic polycarbonate sheet is a polymeric material that is produced by a thermoplastic reaction. The chemical components are formed into granules and then further processed to take the specified shape, color and size.

The production process is regulated by the requirements of TU 6-19-113-87 and GOST R 51136-2008.

Characteristics and properties

Sheet monolithic carbonate can be produced according to GOST, taking into account the requirements for protective glasses, as well as according to TU developed for a specific type of material. At the same time, the main technical characteristics remain the same, since the production process does not change.

There are a number of parameters and properties that can be important when choosing or using monolithic polycarbonate.

- Strength. This indicator has several measurement methods at once: tensile strength - 65 MPa for 3 mm sheets, tensile strength - 60 MPa, withstand shock load reaches 158 J. All these indicators indicate that the material tolerates various influences well. He is not afraid of blows, gusts of wind, contact with atmospheric moisture. Multilayer polycarbonate does not penetrate a bullet when fired.

- Chemical resistance. The peculiarities of the composition make the monolithic carbonate resistant to the effects of various types of chemically aggressive substances. It does not react with alcohol, slightly acidic solutions, organic fats. Ammonia, acetic or boric acid, propane, mineral oil can destroy the structure of the material.

- Melting temperature. It reaches 280-310 degrees Celsius. In this state, the thermoplastic is fluid. The material acquires pliability to bending even when heated to 130 degrees, becoming soft like plasticine. The combustion temperature of polycarbonate significantly exceeds these values.

- Viscosity. It affects the ability of the material not to fly apart into fragments under intense shock loading. It is the high viscosity that helps the monolithic polycarbonate resist torsion, bending, compression, and allows it to hold a bullet in its thickness in case of a direct hit.

- Carrying capacity. They reach 300 kg / m2, profiled sheets have the highest rates.

- Flexibility. Material with different surface textures - both smooth and corrugated - withstands stress during deformation well. For products with a thickness of 3 mm, the minimum bending radius reaches 430-460 mm, for a sheet of 10 mm it varies in the range of 1470-1510 mm.All this makes the material a good choice for creating all kinds of arched structures - both greenhouse and decorative.

- Insulating properties. The thermal conductivity of polycarbonate is lower than that of glass, therefore it allows accumulating the accumulated energy and not giving it away when the external temperatures drop. This property is used when arranging greenhouses. In terms of its soundproofing characteristics, the monolithic sheet is also quite good, its indicators are 18-23 dB, there is the ability to absorb sounds.

- Light transmission. Depending on the transparency and the presence of coloring components, the average is 86-90%. Colored sheets most often have the additional ability to filter harmful and hazardous UV radiation.

- Thermal resistance. It varies in the operating temperature range from +120 to -50 degrees Celsius. Monolithic slabs are less susceptible to thermal expansion, therefore they are less destructible under the influence of atmospheric factors.

- Life time. On average, it is from 10 to 15 years, in conditions of increased loads this figure is halved.

These are the main characteristics and features possessed by a popular modern material - monolithic polycarbonate.

Comparison with cellular polycarbonate

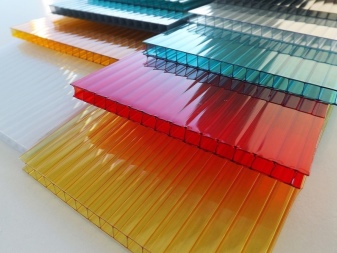

What is the difference between the two types of polycarbonate? First of all - in the structure of the material. The main difference lies in the solidity of one type of sheet and in the presence of cells in the thickness of the other. Honeycombs make the structure less resistant to stress, but better insulate heat and sound.

There is also a difference in other aspects.

- In strength characteristics. They are higher in the sheet monolith. The visor from it will withstand the fall of frozen ice from the edge of the roof. With such contact, the honeycomb structure will simply crumble.

- In the ability to withstand constant stress. The same snow in winter or a strong wind from the gap between the houses will not damage monolithic polycarbonate. Cellular in such conditions will not last long.

- In transparency. The honeycomb structure reduces light transmission, the material does not look too much like glass, there are distortions.

- In aesthetics. It is believed that cellular materials are technical, it is not customary to display them.

- In the price. Here, the advantage will be behind the cellular analogue. It is significantly cheaper than even a flat sheet, not to mention corrugated sheet.

When deciding which option is better, it is worth understanding: each type of polycarbonate has its own purpose, their interchangeability is impossible without prejudice to the case.

Species overview

Monolithic polycarbonate sheet can be solid and profile, can be classified by size and weight, color characteristics and other parameters. In most cases, a transparent material with stable geometric characteristics is used. But there are also non-standard versions of this lightweight plastic, which also deserve attention. It is worth considering them in more detail.

By form

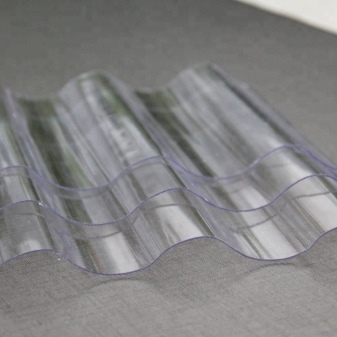

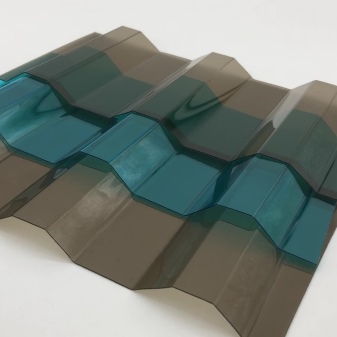

Profiled monolithic polycarbonate is in many ways similar to the analogue of galvanized metal. It can have a different type of relief. The most commonly used are 2 options.

- Wave. There are 2 height parameters. The wavy relief can be 18 or 34 mm deep, 76 and 94 mm wide. This option is especially popular when designing decorative structures and fences.

- Corrugated trapezoidal. With a classic "intake" or "roof" profile. This is the optimal solution for external cladding of sheds, buildings, arbors. Trapezoid sizes range from 37 × 69 × 18 mm to 69 × 101 × 18 mm.

Flat or classic sheet version without corrugation, simple shape, looks more like silicate or acrylic glass. This is the optimal option in terms of translucency, but its strength is significantly lower in comparison with the corrugated one. Flat sheets are also textured - with a kind of embossing on the surface. Such options are not transparent, but retain high light transmittance.

Monolithic polycarbonate with a profiled surface type is often used as translucent inserts in roof structures. It transfers loads much better due to additional stiffening ribs. This is an analogue of slate or metal profile, which can be easily integrated into an existing coating or used as an independent version of the roof.

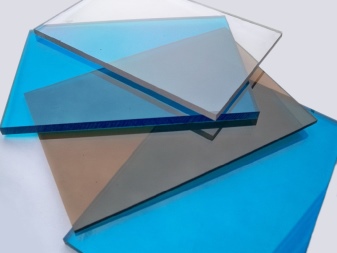

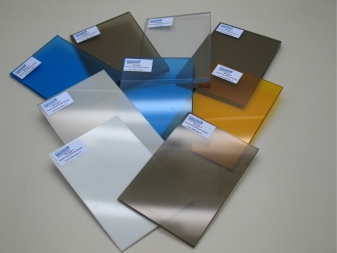

By color

Transparent monolithic polycarbonate is found most often, it is popular and in demand. In terms of translucency, this type of sheet is not inferior to glass. It is well suited for arranging greenhouses, creating panoramic glazing, winter gardens. Its matte counterpart has a light transmittance of about 45-50%, perfectly diffuses the sun's rays, and protects from prying eyes.

The color palette of painted sheets is quite varied. These can be the following tones:

- White;

- lactic;

- black;

- Gray;

- Brown;

- turquoise;

- green;

- yellow;

- metallic.

Some manufacturers are making color polycarbonate even more varied with limited editions in the full RAL color palette. But in free sale it can be seen very rarely.

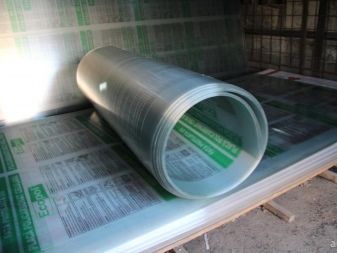

Dimensions (edit)

Since most of the monolithic polycarbonate is extruded, sheet widths are dictated by the performance of industrial equipment. Thus, the width always remains at 2050 mm. The standard length is 3030 or 1250 mm, but larger products are also available - up to 13.5 m per roll.

Profiled sheets can have the following parameters in millimeters:

- 1050x2000;

- 1260×2000;

- 1260×2500;

- 1260×6000.

Standard thicknesses are produced in the following steps: 1, 2, 3, 4, 5, 6, 8, 10, 12 mm.

In addition, there are non-standard solutions up to 2 centimeters thick. The weight of 1 m2 of the product varies depending on its thickness and is in the range of 0.8-3.5 kg.

Manufacturers

In Russia, several large brands are engaged in the production of monolithic polycarbonate. Among the most famous - "Carboglass". SafPlast with its products in the Novattro series is also not inferior, moreover, the company is actively involved in the development of official technical documentation for polycarbonates of all types. Among young Russian brands, the company deserves attention Kronos.

Among foreign firms, Sunnex Is a Chinese company famous for its wide palette of colors. If you want to get an even better product, you can pay attention to the products of the concern Makrolon... The materials of the Israeli brand Polygal plastic.

Applications

Monolithic polycarbonate is most often considered as a good alternative to silicate or quartz glass. A lot is created with its help.

- Translucent partitions. They are in demand in the office sector, in the interior of bars and restaurants, in document processing centers and municipal institutions.

- Arched products. Greenhouses, greenhouses, decorative tunnels and other structures made of flexible sheets on the frame are easy to assemble and are not afraid of loads.

- Sheds and canopies of bus stops, entrances to buildings and structures. Both smooth transparent and tinted or corrugated materials are used here.

- Light boxes and other designs for displaying outdoor advertising.

- Roofing inserts. They are used as viewing windows to increase the amount of penetrating light.

- Vertical glazing residential and commercial buildings.

- Light domes for various purposes.

- Summer gazebos and verandas in private or public areas.

- Advertising and information stands.

- Elements of protective equipment. For example, glasses in the visors of police and military helmets, other parts that require high strength and safety.

- Sports and road fencing. For example, around the hockey rink, such shields, which are good at absorbing blows, are simply irreplaceable.

- Automotive design elements. Glass, headlights, dashboards are made from the material.

- Walls of shower cabins.

The purpose of a particular type of material most often depends on its thickness. With indicators over 10 mm, the sheets are considered roofing, and are also used in the arrangement of road barriers and information boards. The thickness of 6-8 mm is well suited for gardening - this material is used to decorate winter gardens, greenhouses, greenhouses.

Thinner sheets are used for visors and other curly designs, used in advertising, design.

How to work with the material?

At home, a sheet of monolithic or molded polycarbonate can be subjected to different types of processing. Most often, bending, cutting, connection of individual layers to each other by gluing are carried out. This polymer does not create any particular difficulties in processing, it is well suited for cutting with hand or power tools.

Home cutting

Cast or extruded polycarbonate without meshes cannot simply be sawed without prior preparation. Best of all, it lends itself to cutting with a grinder with a disc for metal No. 125 installed on it. In this case, the cut is obtained without burrs and chips. And you can also perform laser cutting of sheets, use a jigsaw with a fine file. The sharper the cutting element, the better the procedure will be.

In the course of cutting, it is worth adhering to certain recommendations.

- The sheet is cut only in a horizontal position, placing it on a clean, flat surface. Any protrusions or other obstructions will lead to cracks or deformation.

- The cutting line must be applied in advance. The most convenient way to do this is with a marker.

- Panels less than 2 mm thick are cut in a stack, connected with clamps. This will avoid cracking the material.

- Cutting must be done from the side with UV protection. The protective film is not removed until the completion of the work.

Elements that are large in size are easiest to cut by placing them on a flat floor surface. A board is laid on top, on which the master can freely move.

How to bend a sheet at home?

Monolithic polycarbonate lends itself quite well to bending, but taking into account its characteristic radius. You can give the sheet the desired shape using a locksmith's workbench and a vice. Transparent or colored material is placed on a workbench, clamped, and then manually adjusted to the desired bending level. It is important not to make excessive efforts to maintain the integrity of the slab.

No preheating is required for the material.

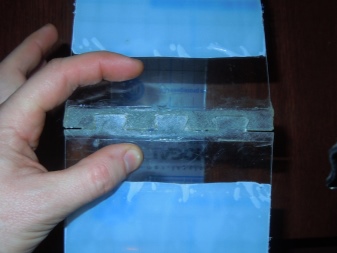

Bonding technology

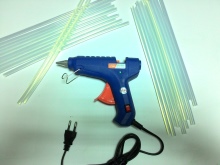

The need to glue polycarbonate most often arises when joining sheets in greenhouses or other structures. The connection of the elements is carried out using special chemical compositions that do not affect the main characteristics of the material. In light, unloaded products - greenhouses, sheds - you can use several options for adhesives.

- One-component adhesives. They are also suitable for mounting polycarbonate sheets on rubber, metal, glass or polymer surfaces. There are many products in this category, you can choose Vitralit 5634, Cosmofen, Silicone mastic. One-component adhesives are characterized by fast curing, they are not afraid of moisture and high temperatures.

- EVA. Adhesives based on ethylene vinyl acetate are suitable for connecting polymeric materials to each other in different planes. It is a good choice for creating multi-layer products.

- Hot curing adhesives. Provides maximum bond strength. The best formulations have a polyamide base.

In structures operated under loads, two-component adhesives should be used - Acrifix, Altuglas. Formulations on a polyurethane base, which form a transparent elastic seam, are suitable. Silicone adhesives are often used to seal joints. Polycarbonate can be attached to flat surfaces with a special double-sided tape on an acrylic foam base.It is recommended to apply adhesives of thermoplastic, silicone, polyurethane types, as well as fast curing with a mounting gun.

Installation features

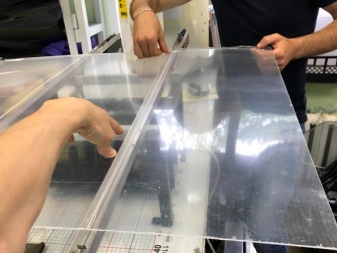

Fastening of monolithic polycarbonate is carried out in two ways. If there are no requirements for sealing the structure, a connecting aluminum profile or other available hardware and accessories are used. It is easy to drill a hole in the material, which allows you to use almost any type of fastener.

Fixation "dry" means through fixing on the frame or the installation of a polymer sheet in a clamp, frame. Fastening is done without significant effort, but one must remember about the linear expansion of the material. Installation is carried out while maintaining technological gaps of 5 mm, with an indent from the edge of the frame.

Rubber gaskets help to seal the through holes.

It is also possible to fix monolithic polycarbonate with a wet method. In this case, you will have to choose the right glue, sealant or polymer-based putty. You can not take alkaline compounds, aggressive solvents - they can destroy the structure of the polymer. The instructions for wet mounting sheets include several steps.

- Degrease the joint areas.

- Perform mechanical cleaning of the joined edges.

- When attaching to metal, rubber, glass, you can use an industrial thermo gun with special rods. Better to choose the model with a spray of hot melt glue. It is better to choose the composition of compatible rods based on EVA, for the strongest connection - polyamide.

- When connecting polycarbonate sheets to each other, a cold-acting liquid composition is applied to the area to be joined. Parts, if necessary, are fixed with clamps. Then it is left for hardening and gluing for the period specified by the manufacturer.

- The loaded elements are connected with silicone glue-sealant or special foam tape.

After the adhesive has hardened, the product can be used for its intended purpose.

Review overview

According to customer reviews, monolithic carbonate costs much more than its cellular counterpart when buying. But it has obvious advantages: attractive and varied design, strength, ease of cutting. It is noted that painted corrugated sheets are well suited for temporary and permanent fencing. Buyers prefer to purchase translucent options with a light transmission of about 45% to ensure privacy on summer verandas and gazebos.

The owners of monolithic carbonate structures also consider the environmental friendliness of this material to be an obvious plus. Even in contact with fire, it does not emit toxic substances. When trying to set it on fire, the sheet practically does not ignite, it quickly dies out. If damaged, the sheet crumbles into traumatic particles, which is also important.

There are also negative responses. They are mainly associated with the ease of damage to the outer layer of the material. On a smooth surface, scratches and other defects are visible from afar. It is worth noting that the UV protective coating is also not very durable, over time its effectiveness decreases markedly.

The following video will tell you about the pros and cons of monolithic polycarbonate.

It was just necessary to glue the polycarbonate. Your article came across in time. Thanks.

The comment was sent successfully.