Ridge profiles for polycarbonate

A ridge profile for polycarbonate is a metal or polycarbonate structure that serves to hide the upper joint of the materials to be joined from prying eyes and harmful weather conditions.

Such a solution will hide ugly seams and protect them from precipitation penetrating inside.

Description

There are many types of profiles. It will not be difficult to select the required thickness, configuration and even color scheme.

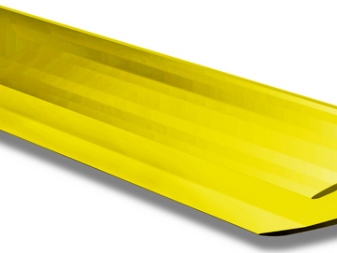

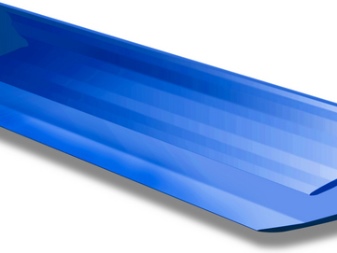

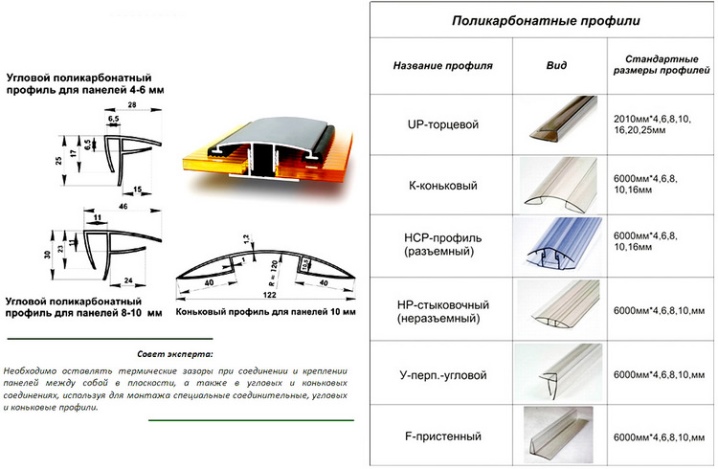

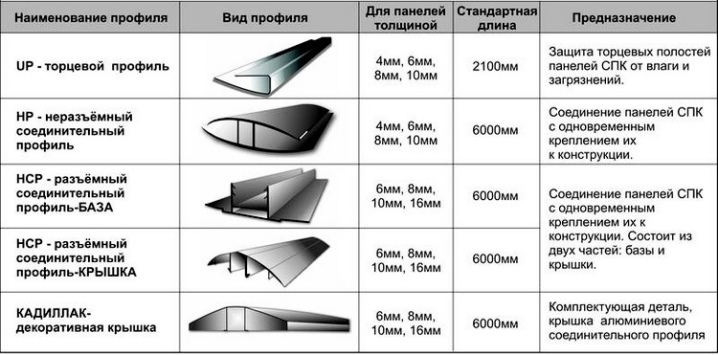

- End UP profile. It is purchased for the purpose of sealing the end cuts. It is a strip in the form of a rectangle without a side, containing a condensate drainage chute inside it. This design is attached to the side of the sheet, preventing dirt and moisture from appearing in the voids of the polycarbonate material. At the same time, it brings a pleasant finished one to the overall appearance of the structure. Such a profile can be made of polycarbonate, or it can be aluminum.

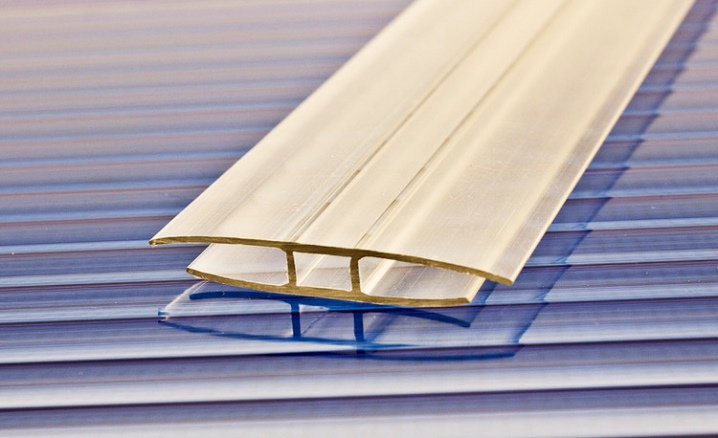

- Connecting HP profile. It is a profile for one-piece polycarbonate. Made in the form of a rail for a flat or arc base of the greenhouse with a monolithic or honeycomb polycarbonate sheet. This addition allows the sheets of material to be joined in the correct way, while protecting the joint from weather conditions. It is worth remembering that neither polycarbonate nor aluminum HP-profiles are used to fasten the sheets to the greenhouse frame. They serve only as an aesthetic completion of the structure and to protect the joint from dirt and water.

- Connecting HCP profile. Its design combines a base and a lid and is priced higher than the HP profile. However, he works out this at the expense of ease of installation. The HCP profile contributes to the reliable fastening of the polycarbonate sheet to the greenhouse frame, while speeding up the installation and increasing the quality of joining the sheets of material. The connecting split profile in its basic configuration contains the lower part, which is rigidly fixed on the supporting base, and the upper part, which is snapped into place during installation.

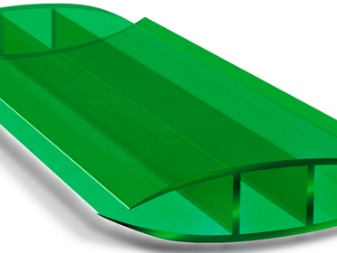

- Ridge RP-profile. This type of profile is used when joining sheets of cellular (or non-cellular) polycarbonate at optimal angles. The latter can be quickly changed right during the installation process. The design of the ridge profile includes two end extensions, which are connected by a joint. It just gives you a convenient and quick way to change the angle. This flexibility will allow you to seal the ridge joint as efficiently as possible and improve the appearance of the structure.

- Wall mounted FP. Provides a sealed connection of the polycarbonate roof to the adjacent wall. Its attachment can be carried out to wood, metal, monolithic joints. During installation, such a profile will play the role of an end piece and an adjoining unit. Many installers also use it as a starter mount for polycarbonate sheets. This is done due to the presence of a special groove in the profile. It is into it that the end face of the roofing sheet enters and is tightly held there.

- Corner FR. It is used when joining canvases of various types and configurations. This design plays the role of a regulator of the angle of joints between two polycarbonate sheets. The gusset has increased reliability and rigidity in comparison with other types of profiles, it resists twisting better.With its help, specialists seal the corner joints between the polycarbonate material.

Dimensions (edit)

When choosing the thickness of the material for the greenhouse, you need to be guided by external conditions, as well as the purpose of the future structure.

For arched greenhouses, polycarbonate sheets with a thickness of 4-5 mm are usually used.however, it is increased to 6 mm if high snow cover is expected.

Two-chamber polycarbonate with a thickness of 16 mm and more is used for the installation of structures that require increased thermal insulation.

If, in conditions of constant cold and precipitation, it is necessary to install a year-round greenhouse, then polycarbonate two-chamber sheets with a thickness of 25 mm and higher are used.

At the same time, it should be understood that the docking (connecting) profile for polycarbonate material should be selected according to the same principle: the more loads are expected, the more the choice should lean towards aluminum extrusions.

How to fix the profile correctly?

For the correct installation of the profile, you must follow some rules.

- The polycarbonate sheet connected to the corner structure must fully match it in size.

- Thermal washers should be equal in thickness to the plastic sheets.

- It is necessary to fasten the sheets by orienting them upward with a special layer that reflects UV radiation (usually a characteristic marked protective coating is glued to the right side).

- Do not forget about such a constructively important element as the clamping bar. It will give the structure additional strength and durability.

- A fence should be used to insulate / seal each open end.

- Do not forget that a thermal gap of 3-5 mm must be provided between the polycarbonate sheets.

- An aluminum product will be the best option for sheets with a thickness of more than 10 mm. If the sheets are thinner, plastic material can be used.

For more information on ridge profiles for polycarbonate, see the video below.

The comment was sent successfully.