What is clear polycarbonate and where is it used?

Polycarbonate is a popular material, the quality of which is appreciated by many consumers. It comes in several types and comes in different color variations. Let's consider in the article what transparent polycarbonate is, and find out where it is usually used.

Peculiarities

Polycarbonate is a special material - polyester of carbonic acid in combination with bisphenol A. This polymer belongs to the thermoplastic group.

Due to its technical characteristics, transparent polycarbonate is allowed to be used as a replacement for conventional silicate glass.

The transparency of the material in question is different: complete or partial... Meet and colored polycarbonate sheets. Different versions have different levels of light transmission. Polycarbonate is characterized by good impact resistance, coupled with flexibility. Typically, this material is 32 mm thick. The weight of polycarbonate sheets is ultra-light - on average it reaches from 4 to 8 kg per 1 square meter of material.

Today polycarbonate has become a very popular and demanded material. This sheet product has won wide distribution due to a large number of positive qualities. Let's get acquainted with their list.

- An important plus of polycarbonate is its low weight. The plastic, which is based on carbonic acid and bisphenol, is light enough to fit on a simple metal and wood frame. This suggests that the installation of such sheet materials is simple and quick.

- Polycarbonate boasts a good level of flexibility. Sheet material can bend without breakage. It is thanks to this feature that polycarbonate sheets can be used for the manufacture of structures of non-standard shapes. For example, it can be arched or curly roof bases.

- Polycarbonate is a material that allows sunlight to pass through. Transparent plastic can easily pass up to 92% of the visible light spectrum, which is why it is often used in the construction of high-quality greenhouses in the local area. For the construction of such structures, only transparent sheets are suitable, and opaque specimens are usually used for roofing, the manufacture of road signs and other similar elements.

- Polycarbonate is an impact-resistant material. High-quality polycarbonate sheets withstand considerable loads and impacts of great force, without being subjected to deformation.

- Polycarbonate is a relatively inexpensive material. It is sold in many home improvement stores and shopping malls. Often, buyers choose polycarbonate sheets, since they are cheaper than other materials of this kind.

- The sheet material in question can easily withstand temperature changes. Products do not lose their original shock resistance, even when outside the window is 40-degree frost. Heating up to +120 degrees Celsius also cannot harm the transparent polycarbonate.

- The material retains heat much more efficiently than the same silicate glass. The average heat transfer coefficient of the products under consideration reaches 4.92 W / m2.This suggests that polycarbonate is an economically viable material that can be a good alternative to ordinary glazing.

- The sheet material boasts a long service life. High-quality transparent polycarbonate can serve for 20-25 years without any problems.

- The sufficient strength level of polycarbonate is very handily combined with flexibility. Even if the sheet material collapses, it simply cracks, and does not break into small fragments.

- The material in question is fireproof.

A large number of advantages have made polycarbonate an indispensable material in its category.

Comparison with colored polycarbonate

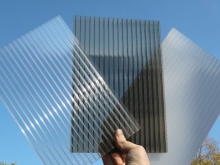

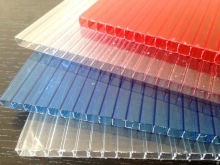

Modern polycarbonate sheets come in several different types. In addition to transparent, colored products can also be found on sale. Many buyers ask a reasonable question: how are they different from each other? Let's find out what are the differences between the specified subspecies of sheet material.

- The first thing to look out for is cost. Colored polycarbonate sheets are more expensive than transparent ones.

- In the production of colored polycarbonate plates, special tinted polymer capsules are used. When transparent products are produced, such components are not involved. The use of these granules affects the light transmittance of colored polycarbonate, so it is no more than 85%.

- Colored sheets are used in a wide variety of fields and fields, which cannot be said for colorless products.

- Some people think that transparent sheets look simpler and cheaper than colored sheets.

It is difficult to say which of the reviewed materials is better. It all depends on the purpose for which polycarbonate is selected.

Varieties

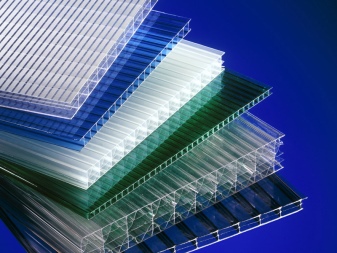

As mentioned above, polycarbonate comes in several varieties. Each of them has its own pros, cons and performance characteristics. Let's take a closer look at the existing types of polycarbonate sheets.

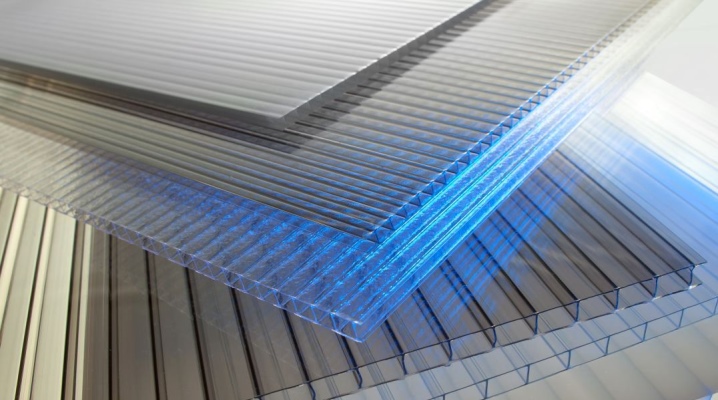

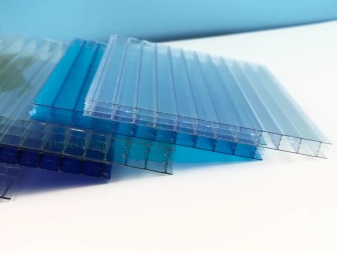

Cellular

A very popular type of material. It is most often used to build efficient, good quality greenhouses.

And also cellular polycarbonate is suitable for the construction of gazebos, awnings, greenhouses and even fences. Such a material transmits sunlight well, scattering it at the same time.

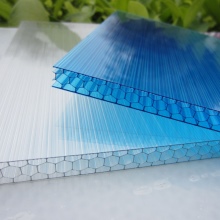

The cellular type of polycarbonate differs in such parameters.

- It is very resilient, due to which it can absorb small impacts.

- It has internal partitions in its structure. It is thanks to them that sunlight is scattered, which is transmitted by cellular polycarbonate.

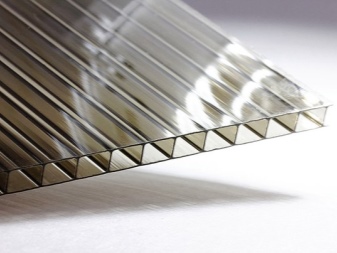

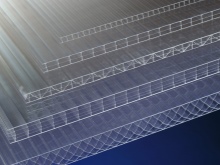

- The material is durable. Available in the form of two-layer or multi-layer sheets. Stiffeners can be perpendicular or diagonal. The more of these ribs, the more durable the material becomes, and also its insulating qualities increase.

- Honeycomb sheets are characterized by a sufficient ability to transmit light, depending on the specific thickness.

- Honeycomb transparent polycarbonate sheets are usually manufactured with additional UV protection. It protects the plastic from premature wear.

But the cellular material has certain drawbacks.

- When there are many stiffeners in such polycarbonate sheets, this negatively affects their light transmittance.

- This material becomes opaque very easily. Coloring of absolutely any color strongly colors the sheets.

- The level of impact resistance of honeycomb carbonate is not so high, especially in comparison with the monolithic version.

Monolithic

This subtype of polycarbonate is in many ways superior to all other existing materials with a transparent structure. It has many positive characteristics.

- Monolithic flat sheets have excellent impact resistance. In this parameter, this type of polycarbonate is ahead of silicate glass 200 times, polystyrene - 150 times, and organic glass - 60 times.

- The material does not lose strength at temperatures from -50 to +130 degrees.

- From a possible impact, the products crack, and do not turn into a heap of fragments.

- Monolithic polycarbonate is not subject to decay, does not grow moldy and is not afraid of contact with water.

- It is a chemically resistant sheet material that is not afraid of contact with soap-based detergents, salts, fats, industrial oils, greases and even acids. Not every material can boast of such qualities.

- UV resistant due to the presence of a special protective film.

- The material is quite flexible. Does not collapse in the event of an increase in the permissible bending radius.

- It is thermally conductive.

Monolithic polycarbonate sheets are not without drawbacks.

- The polymer can be destroyed if it is exposed to alcohols containing methyl, alkalis, solutions and ammonia vapors, acetone.

- The material cannot boast of good sound insulation.

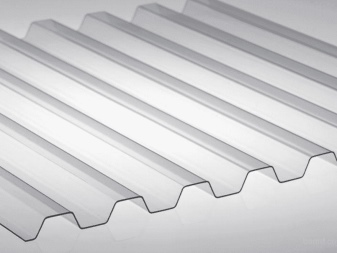

Profiled

This material is produced in the form of sheets of a monolithic type or wavy shape. Smooth and curved pieces are on sale. Let's analyze the main advantages of such polycarbonate.

- The material is strong yet flexible and soft. Has stiffening ribs.

- Easy and simple to process.

- Easy to install.

- Thermal and sound insulation qualities meet the required standards.

- Light transmittance of profiled polycarbonate reaches 92%.

- The material is well protected from ultraviolet radiation.

- Has a democratic price.

Among the shortcomings, it is worth noting the following:

- it is very difficult to make a sealed structure from a profiled sheet;

- material can accumulate static electricity;

- it is impossible to remove snow from it with a shovel, as it can cause serious damage.

Dimensions (edit)

Transparent polycarbonate has different sizes. In specialized stores and shopping centers, you can find high-quality sheets with dimensions of 20x1100 cm, 1.25x2.05 m, 2.05x3.05 m, 3.05x2.05 m, 6.0x2.1 m and others.

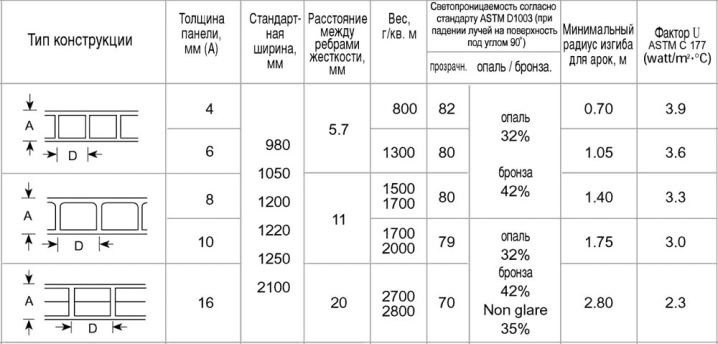

The thickness of different polycarbonate sheets is represented by parameters in 1 mm, 2 mm, 3 mm, 4 mm, 5 mm, 6 mm, 7 mm, 8 mm, 9 mm, 10 mm and so on (up to 16 mm). Buyers can select both thinner and denser material depending on the purpose for which it is being purchased.

Scope of application

Today, polycarbonate is found very often, since this material is used in a wide variety of areas and fields. Consider where exactly this sheet material is used:

- it is installed as an alternative to glazing windows of various buildings;

- very good greenhouses and greenhouses are made from polycarbonate in the adjoining areas and not only;

- the material is great for the manufacture of awnings and canopies, for example, over the front door;

- if you need to build a transparent partition, polycarbonate will be an excellent solution;

- the material can be used as glazing for doors installed inside the building;

- suitable for the production of outdoor advertising objects.

This is not the whole list of ways to use transparent polycarbonate. Often, whole garages are built from it, laid as a roofing material, original fences are built and much more.

Installation instructions

Transparent polycarbonate is attractive for its simple installation. Let's consider what stages it consists of.

- Sheets can be installed wet or dry. The second option is more often chosen. With the dry method, special putties are used, which are applied to the frame contour and the edges of the sheet material.

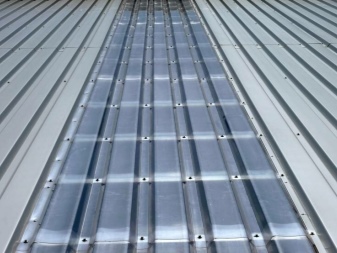

- In accordance with the dry method, polycarbonate sheets are attached to self-tapping screws with sealing washers.

- All mounting holes in the sheets must be drilled out in advance of starting work. It is recommended to maintain a fastener pitch of 0.5 m. The smallest distance of the holes from the edges of the sheet is 2 cm.

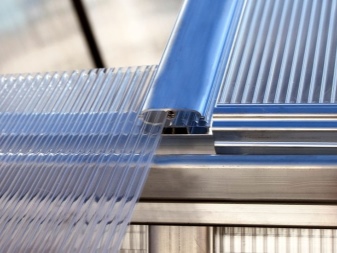

- Monolithic sheets are installed on an aluminum or polycarbonate profile. A lathing made of wood is also suitable, but only if there is a special docking profile.He will connect the edges of the polycarbonate sheets, cover the upper seams from precipitation.

The profiled type of polycarbonate is mounted using the same technology as other undulating material - euro slate.

The comment was sent successfully.