How and how to cut polycarbonate for greenhouses?

Strong, lightweight, flexible polymer plastic, or, more simply, polycarbonate, has recently become a real competitor to glass and polyethylene, which were previously used in the construction of greenhouses. How to cut it correctly and quickly, what tools are needed for this and what mistakes can be avoided when cutting is described in this article.

Tool overview

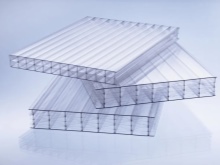

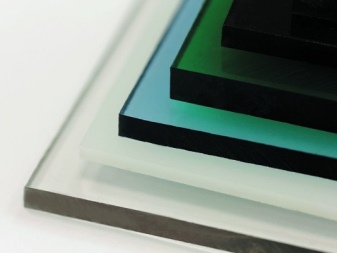

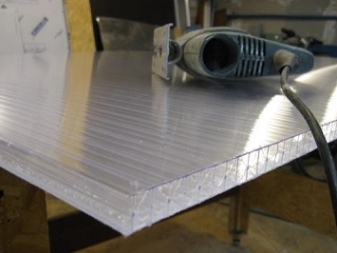

Before choosing a cutting tool, you need to decide which type of polycarbonate to buy - monolithic or honeycomb (cellular). Of course, every gardener decides for himself, but experts advise using a cell phone. Despite the fact that both species have a similar chemical composition and consist of similar substances, in terms of their technical characteristics, the cellular one is superior to the monolithic one.

After you have chosen the type of polycarbonate, you need to decide on the thickness. It varies between 4-16 mm. Here you need to take into account the main points: what the structure will be like, for what season is the greenhouse, what will be the step of the crate.

The optimal sheet width, verified by practice, is 4-10 mm.

We chose, bought, now it is necessary to make a decision - to entrust the cutting to a professional master on a laser (milling) machine or to do everything by hand. The process of cutting plastic and installing a greenhouse is simple, so even a beginner with minimal knowledge in construction can handle it.

Don't worry, all the tools you need to cut polycarbonate sheets can be found in your regular “householder's kit”:

- knife;

- hacksaw;

- Bulgarian;

- electric jigsaw;

- a circular saw.

Now more about each instrument. A knife for cutting can be anything - shoemaker, clerical, construction or sharp kitchen. In the first two types of knives, it is advisable to insert new blades before work. The disadvantage of this tool is that it can cut only sheets of small thickness - 4-6 mm.

The hacksaw does not have to be for metal, you can take it for plastic. The main thing is that she has a small tooth. The grinder should have an abrasive wheel of 125. The model is not important here, even the most inexpensive will do. A file for an electric jigsaw must also be chosen with the smallest and most frequent tooth. Such a tool is quite suitable for cutting out semicircular parts or other curly lines.

The process of cutting polycarbonate for greenhouses is not particularly difficult, you just need to comply with some conditions.

Cut open

Polycarbonate has a standard width of 2.1 m, and there are basically two lengths - 6 meters and 12 meters. For the manufacture of greenhouses, the first option is often used. Standard building sizes are 3x4 and 3x6. These figures are derived in a practical way. The fact is that if the height of the greenhouse is less than 3 m, then such popular summer cottage crops as tomatoes and cucumbers will not be able to develop correctly. And with a greenhouse length of more than 6 m, ventilation will be poor and various pathogenic organisms will appear. You can spread a sheet of polycarbonate directly on the ground. But first, you need to clear the area where you plan to cut from pebbles, branches and various debris.

Polycarbonate is a flexible material, so such unnecessary particles can leave scratches or other minor defects on it. The ideal option is to lay large sheets of chipboard or fiberboard on the ground.On a sheet of paper, you should draw a diagram of the future greenhouse with dimensions to scale. Then, with a marker, make a marking along the entire length of the polycarbonate, in accordance with the diagram, but in real size. You cannot move directly along the spread sheets! If there is such a need, then you can put a long wide board.

A small nuance: when cutting cellular polycarbonate, marking is optional. In this case, the cells themselves act as a reference point.

Calculation of polycarbonate

The amount of material that will be needed to build a greenhouse depends entirely on its size and shape. The simplest to install are arched greenhouses of standard sizes.

Calculating how many polycarbonate sheets are needed for the construction of a 3x4 m greenhouse is also not very difficult. A standard sheet of material is 2.1x6 m, the length of each of the two steel arcs is 6 m, the width between the spans is 2 m, so you need to purchase 2 sheets of polycarbonate to cover the greenhouse. Another sheet will be needed to make the front and rear gables.

Accordingly, the amount of material for a 4x6 m greenhouse is also calculated. It is said that for her it is necessary to buy 3 sheets for the walls and 2 sheets for the gables. If you need to calculate the number of polycarbonate sheets for a greenhouse of a completely different size, you can use this formula: N = L / 2 + 1, where L is the length of the greenhouse (m). If a greenhouse of a different shape is planned (wall, gable, polygonal, Dutch, pyramid-shaped), then the amount of consumables for it can be calculated using an online calculator.

Direction

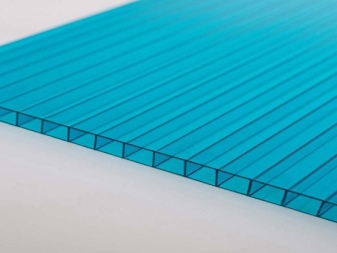

It is important when cutting polycarbonate to correctly orient its panels in the direction of the slope from top to bottom or along the bend of the frame. To find out the direction of the sheet, you need to look at the markings that are written on the protective film. Cellular polycarbonate should be cut in the direction of the honeycomb-tube, but not across or diagonally, as the material may crack.

If there is a need to cut across, then this must be done in two stages: first, cut the top layer of the sheet, then cut through it to the end.

Cutting steps

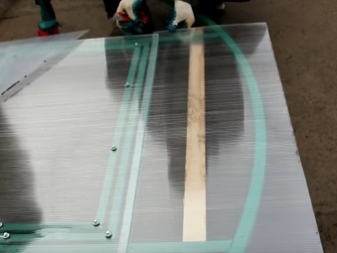

After all the calculations have been made, the cutting lines have been drawn, you can proceed directly to cutting.

- You need to put boards under the sides of the canvas. This is done so that there is a gap under the cut line, which will minimize vibration when cutting.

- If you plan to cut the sheet in a semicircle, then it will have to be turned periodically. You can use a grinder to cut greenhouse parts in a straight line. And in order to correctly cut a sheet of a rounded or curly shape on the pediment of the structure - an electric jigsaw.

- After work, all sections of the sheets must be blown with a strong stream of air to remove excess particles. This is especially true for cellular polycarbonate.

- To prevent condensation from accumulating in the honeycomb, dust, dirt and insects, before assembling the greenhouse, seal the cuts with a special sealing tape. It should be perforated on the bottom side, and solid on the top.

Possible mistakes

Although the cutting process is straightforward, beginners can make some common mistakes.

- We removed the protective film from the polycarbonate. In no case should this be done, since during cutting there is a possibility of accidentally damaging the sheet.

- The formed sawdust was not removed with air. They interfere with making a straight cut.

- They left a lot of waste material. To avoid this error, it is recommended, after drawing up a diagram on a sheet, to cut out some complex parts from cardboard. Then, applying them to polycarbonate sheets in different versions, choose the best one and only then cut.

- One sheet of polycarbonate was cut. If the thickness of the sheets is 4-6 mm, then it is better to cut them several pieces at once, folding them in a "stack". This will help avoid cracks.

- The UV-protected side of the sheet was placed inside the greenhouse.In this case, exposure to sunlight will negatively affect the properties of polycarbonate and reduce its service life. To prevent this from happening, you need to carefully examine the polycarbonate and turn the side with UV protection towards the sun.

- The hollow channels of the sheets were placed vertically. Polycarbonate is a hygroscopic material, therefore, with such an arrangement of channels, water will accumulate in them during operation.

In conclusion - a few simple tips when buying polycarbonate, which will help you avoid mistakes:

- examine the sheets for scratches, cracks, the integrity of the outer layer, non-uniformity of painting of colored panels;

- ask to show a quality certificate issued by an accredited laboratory specifically for this batch of products;

- lightly press on the polycarbonate sheet - strong deflections should not remain on it;

- if you see the "turbidity" of certain areas, you should not buy such material.

Let's summarize:

- polycarbonate for greenhouses is better to purchase transparent honeycomb 4-10 mm thick;

- accurate calculations of material consumption can be carried out on an online calculator;

- when cutting plastic, you can use different tools depending on the tasks;

- after cutting the polycarbonate, the cuts should be blown out and sealed with a special tape.

This modern material can be used to build not only greenhouses for growing crops. It is also good for the construction of a terrace, a summer cottage, a summer shower, a bath tub, a fence, various sheds and canopies (for a sandbox, pool, car and other equipment).

For information on how to evenly cut polycarbonate for a greenhouse, see the next video.

The comment was sent successfully.