Characteristics and Uses of Polyethylene Foam Sheet

When carrying out various construction works, it is often necessary to create a moisture-proof, noise-insulating or insulation layer. Often, special foamed polyethylene sheets are used for the manufacture of such surfaces. Today we will talk about what this material is, consider its varieties and applications.

Peculiarities

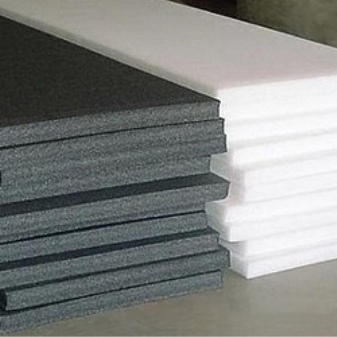

Foamed polyethylene is in the form of soft sheets of relatively thin thickness. They are rectangular and have a fine-grained structure. Such material is quite elastic and soft, it is usually slightly warm to the touch. Polyethylene foam in sheets is produced by extrusion or injection molding of the foamed mass under a certain pressure. In this case, polyethylene of varying degrees of density can be used. The material has low thermal conductivity, it is considered absolutely safe for humans and their health, because freon is not used for its production. And also polyethylene foam boasts excellent water-repellent characteristics.

This kind of material is pretty easy to work with. It is able to significantly reduce the possibility of ignition of other substrates used, therefore it is often used for additional protection of wooden structures. Foamed polyethylene has a high level of wear resistance and durability. It is practically not damaged by small rodents or insects.

The material has a low cost, so it will be affordable for almost any buyer.

Views

Foamed polyethylene sheet is of several main varieties.

- Unstitched. This option is the cheapest. For its manufacture, extrusion is used, while a molten polymer mass is taken as a basis. Such a workpiece is filled with gas (most often butane). At the same time, in the process of pouring into the mold, the mixture comes under the influence of atmospheric pressure, small gas bubbles tend to come out to the surface, in this form they quickly solidify and form a cellular structure. Typically, this technology allows you to create a material with a large pore structure.

- Chemically stitched. For the manufacture of this type of foamed polyethylene sheet, almost the same technology is used as in the previous version. But at the same time, a special treatment with hydrogen peroxide is used as an additional procedure. It makes it possible to remove all possible defects in the material. At the same time, the base becomes much denser, the cells are smaller.

- Sewn by physical or radiation means. This type of polyethylene foam is the most expensive. In this case, the crosslinking of the molecules of the polymer mass occurs due to the flow of electrons, which are emitted by radiation. Irradiation allows the formation of cross-links, which significantly strengthen the molecular lattice of the material. At the final stages of production, the most elastic and soft base with an even surface is obtained, while it can withstand significant pressure. Polyethylene foam, sewn in this way, recovers its original shape much faster after deformation, and it also adheres much better than previous types to other materials.

Such polyethylene foam sheet can vary depending on the size.First of all, when choosing a material, you should pay attention to the thickness of the sheet. As a rule, it can vary from 20 to 50 mm.

The width of each individual sheet can also be different. For standard models, it can be 600-1200 millimeters, but there are samples with other values. The length of the product can reach approximately 1500-3000 millimeters.

Applications

Foamed polyethylene can be used in various areas of construction, but most often it is taken to create a reliable layer of sound insulation, as insulation, moisture protection... The material can be attached to floors, ceilings, wall coverings. If you want to enhance the insulating properties of such a base, you can supplement it with thin aluminum foil, which is glued to only one side of the sheet. Such foundations are most often laid on concrete structures - in this case, they act as special heat shields, reflecting infrared radiation into the interior space. In this way, heat will be conserved much more efficiently.

This type of polyethylene in sheets is sometimes used to create packaging. An unstitched variety is better suited for them, while this type is not recommended for installation work. Foamed polyethylene sheets will be the best option for creating an additional sealing layer for doors and glass units. They are also used in cases where it is required to carry out the most accurate transportation of other materials.

Sheets are widely used in mechanical engineering. Most often, such material is used as a reliable insulator for various refrigeration equipment and air conditioning systems. Sometimes such polyethylene is used in the production of double-sided tape, various mounting tapes, and individual elements designed to absorb vibrations. In heavy-duty trucks, with the help of such material, insulation is often created in the luggage compartments.

Foamed sheets are also used in the medical field. There they have found wide application due to their elasticity and flexibility: products easily regain their shape even after severe deformations. Basics with such characteristics will be an excellent option for the production of various corsets, shoe insoles.

Today in stores, consumers will be able to find various small rugs made from this material. They allow you to sleep on the ground, while reliably protecting the human body from hypothermia.

In the next video, you will find a detailed overview of expanded polyethylene sheet.

The comment was sent successfully.