All about cellophane

For many centuries, man has striven to create something durable, lightweight and convenient for packaging food and other things. The advent of polyethylene, and with it cellophane, became a real breakthrough, which significantly improved everyone's life, making it many times more convenient. In addition to the benefits, there are certain negative sides to the use of cellophane, but with correct and moderate use, this material is necessary and useful for humanity.

What it is?

Cellophane is a material used as packaging for food and other products. Thanks to the transparent structure, it is possible to see the contents without revealing the package. Cellophane looks quite dense, and if the integrity of the package is preserved, then it is extremely difficult to break it, however, with any hole or cut, the package or bag will not withstand.

The production of cellophane began in 1912, it was actively used until the creation of polyethylene. The new material was more promising and convenient in everyday life, so they began to refuse cellophane.

Now almost no bags are produced from this material, but they are actively using it for wrapping candy boxes, cheeses, sausages and other goods that need dense but transparent packaging.

Due to the popularity of polyethylene, a problem has arisen with the pollution of the planet, since bags and other polyethylene products take an extremely long time to decompose, creating huge garbage dumps around the planet. The issue of environmental protection has become very acute, so many countries have limited the use of these products, and many began to restore the production of cellophane bags. Due to its composition, the decomposition period of cellophane is several times less than that of any polyethylene product, which makes it possible to significantly reduce environmental pollution.

The characteristics of cellophane make it possible to understand what exactly makes it more versatile and convenient in everyday life. One of the problems encountered in the process of disposing of packages is their flammability. Plastic bags burn quickly, which causes a fire hazard, while the melting point of cellophane is much higher, and the material only deforms from fire.

Cellophane allows moisture and air to pass through, and polyethylene products have a high density and hermetically seals the contents. The cellophane is thicker, and if you compress it, you can hear the characteristic noise and rustling, while the plastic bag does not rustle.

Since the scope of use of cellophane may differ, there are markings by which you can choose the right product with certain indicators. Technical cellophane is usually hard, food-grade cellophane is softer; on sale you can find transparent and black products.

The material is not hazardous and will take significantly less years to decompose than its polyethylene counterpart.

History of origin

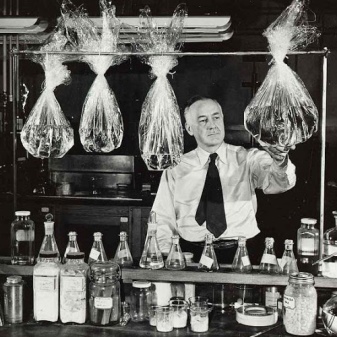

The creation of cellophane was the result of a situation that happened back in 1900 to a Swiss scientist and textile technologist. Jacques Brandenberger, visiting the restaurant, saw wine spilled on the tablecloth, and the waiter had to replace the linen from the table. As a textile specialist, Brandenberger decided to create a material that would keep moisture out and repel it.All his attempts were in vain, but he managed to create a transparent film that could be placed on top of the fabric.

Success allowed Brandenberger by 1912 to create an apparatus that produced transparent film in large quantities. The scientist named the new product "cellophane", using the words "cellulose" and "transparent" as a basis. Production went well, and a year later Brandenberger opened another factory in Paris, and by 1923 the scientist had signed an agreement with the Americans, and his products spread to the United States.

Despite great success, Brandenberger cellophane had a significant drawback: it was moisture permeable. In 1927, the American William Church figured out how to fix this problem. He added nitrocellulose processing to the film production process.

With the advent of moisture-proof cellophane, it became possible to use it for food packaging, which extended the shelf life of products many times over. The popularity of cellophane products grew very quickly and conquered new continents and countries. In Russia, the active use of cellophane began in the 70s, when the new material began to be actively used in various fields.

The emergence of new materials gave impetus to the development of this direction, and soon polyethylene appeared, which became many times more popular and is still used today.

Views

Cellophane film is a product necessary in various fields, so its popularity remains consistently high. Quality control at enterprises is carried out in accordance with GOST 7730-89 for cellophane. In connection with the different scope of application, the types of material used for packaging can be distinguished:

- food products;

- sausage and cheese products;

- candy boxes;

- perfumery products;

- Christmas tree toys.

Depending on the purpose of use, cellophane can have a different density: from 30 to 45 g / m2. There are 2 main varieties of this material: titer 1 with a density of 33 g / m2 and titer 2, whose density is 45 g / m2. To purchase a product for packaging food, you need to look for cellophane in rolls marked "P". For medical and technical purposes, the packaging will be labeled with the letter "T".

In addition to density, it is possible to choose cellophane by width. The smallest rolls are 15 cm wide, and the largest rolls reach 1m 20 cm. In factories, they can wind up rolls to order or produce standard packages.

If we consider other packaging options, then cellophane surpasses analogues in terms of decomposition rate: any cellophane products completely disintegrate in a few years, while polyethylene analogs go the same way in 300 years. This fact is confirmed by multiple studies, cellophane complies with the European standard for biodegradation of packaging materials EN 13432.

In addition to rolls, cellophane can be found in sheets.

How is it different from polyethylene?

Faced daily with cellophane and plastic bags and other products made from these materials, it is difficult to believe that such similar products are radically different. The difference between them starts with the fact that cellophane is made from natural components, and polyethylene is made from artificial ones. To more accurately understand the differences between these materials, it is worth understanding them more in detail.

Cellophane | Polyethylene |

The raw material for production is cellulose, which makes the product biodegradable and harmless to nature. | Created by chemical synthesis of gaseous ethylene hydrocarbon. |

Due to its composition, this material has a sweetish flavor. | There is no taste whatsoever. |

The ability to apply paint and drawings that last for a very long time and do not wear off. | Short-term preservation of any drawing. |

Cellophane bags are hard, rustle when touched, have a smooth surface. | Plastic bags are soft, easily wrinkled, may have an irregular surface, slightly greasy to the touch. |

With any damage, the material tears very easily, it is not resistant to damage. | Withstands heavy weight well, is difficult to deform; |

Cellophane products can be glued, but they do not lend themselves to heat treatment. | Polyethylene products cannot be glued, but damage can be repaired by heat welding. |

Two materials so similar in appearance, but so different in characteristics, perform different tasks, therefore, for each of them there is a place in the market for goods and services. The popularity of polyethylene is higher, since the costs of its production are much lower, and the cost of one bag will be much cheaper than cellophane.

In addition to these differences, it is worth mentioning that the cellophane surface is moisture and air permeable, while polyethylene products are completely sealed. Another important point is resistance to open fire.

If the polyethylene instantly ignites, which can cause a fire, then the cellophane begins to melt and shrink, which is much safer.

Application methods

Due to its air and moisture permeability, cellophane has found application in the production of wrappers for cheese and sausages. It is this kind of packaging that allows the product to "breathe", which does not allow it to disappear, and at the same time significantly extends the shelf life of the product. The use of cellophane for packaging bread makes it possible to keep it fresh for up to 5 days, which was previously impossible.

This material has shown excellent properties in the confectionery industry. Packaging of sweets, bars, packaged sweet products - all this looks neat and has a pleasant appearance due to bright patterns on the surface. Cellophane keeps the contents securely.

The material is also used for protective and decorative purposes, covering any size box. It keeps the contents inside, prevents cardboard or other surfaces from rubbing, while maintaining an attractive appearance of the product. Transparent film makes it possible to view the object of interest from all sides without printing it. Colored film will transform any gift, hiding the contents and making a real surprise out of any thing.

Comparison of polyethylene and cellophane in the video below.

The comment was sent successfully.