Features of sweepers

One of the main tasks of public utilities and road services is the cleaning of roads and sidewalks. And if in the old days a large army of janitors was engaged in bringing cleanliness and order to the streets, then over time the cleaning process was mechanized. Sweepers replaced people.

Purpose

With the advent of highways, the issue of cleaning them has become quite acute. This is due to the fact that movement on an uncleaned track during rain or snowfall is a significant hazard. In this regard, every night special equipment comes out onto the streets, designed for cleaning sand, mud, solid debris and snow. The passage of sweepers contributes to an increase in the coefficient of adhesion of the wheels to the road by 15%, which, in turn, significantly reduces the energy loss of the engine spent on wheel slip.

In addition to highways, road sweepers are widely used for cleaning runways, cleaning squares, squares, sidewalks, courtyards, railway stations, bus stations, sports grounds and museum complexes. In addition, this technique is indispensable when cleaning large factory areas and industrial areas.

The second important function of the PIP is to improve air quality. The fact is that up to 40% of roadway pollution is made up of fine particles that rise into the air and hang in it at a height of one and a half to two meters. Due to the low rate of their settling and the high intensity of traffic flow, a persistent blanket of dust and exhaust gases forms over the uncleared road. In case of untimely cleaning of roads, a dirty cloud will be constantly above the road.

As a result, the sanitary and hygienic norms regulating the presence of harmful impurities in the air will be seriously violated. Timely street cleaning with the help of PUM does not allow the concentration of dust particles to be exceeded, which leads to a general improvement in the ecological situation.

Device and principle of operation

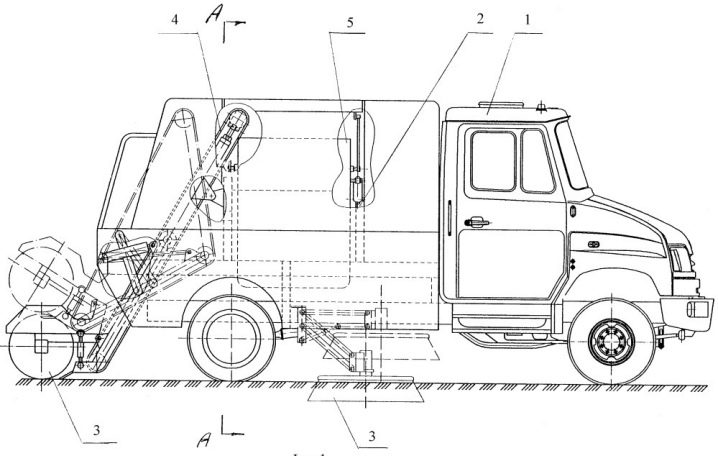

Sweepers are independent mechanisms equipped with rotating brushes with a cylindrical or conical design. Each device is equipped with a hydraulic or pneumatic dust collector and a device for feeding the collected waste into a special tank. Some models of the PUM are equipped with a wide socket for placing there manually collected garbage. This allows the operator to perform high-quality cleaning in places inaccessible to machines.

On foreign models, a front washer is often installed, which is located on the front bumper. It consists of washing combs and brushes mounted on a swivel console. Domestic units based on ZIL and MAZ are often equipped with additional washing guns and hoses. Also, all modern models are equipped with a built-in system for cleaning waste air masses, and some are even equipped with a liquid regeneration function.

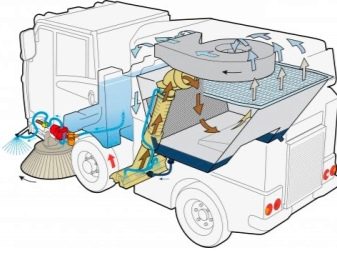

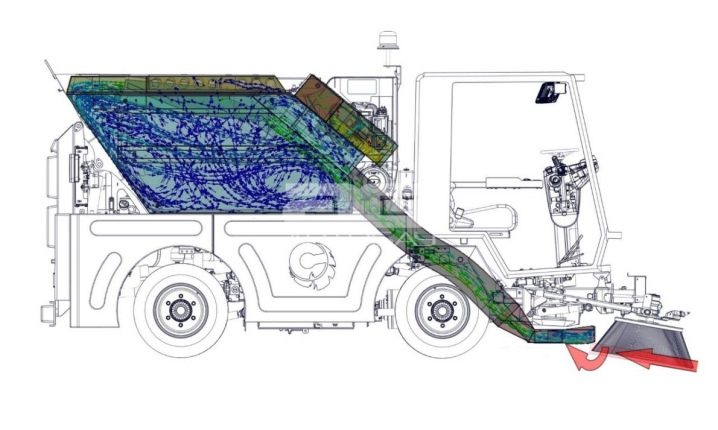

Despite the fact that the device and equipment of different models are noticeably different, their principle of operation is very similar. So, when the unit is moving, tray brushes sweep sand and debris to the central brush, called a pick-up. It feeds debris to the suction pipe, through which it moves through the pipeline system and enters a special container - a sealed trash can, located in the back of the case on most models. Debris is sucked into the pipe not only mechanically, but also by vacuum, in which a pump and a fan are used to form rarefied air.

In more outdated domestic samples, the suction process does not occur. In them, the garbage is fed by two trough brushes to the central one, which sweeps it onto a conveyor, which has a mechanical or pneumatic design. Further along the conveyor belt, the garbage moves to the receiving container and is poured into it.

Varieties

Sweepers are classified according to the functionality of the units. According to this criterion, there are three types of equipment.

Sweeping

Such models are intended only for moving the swept away debris closer to the side of the road or the edge of the roadway. These units are equipped with a cylindrical brush installed at a certain angle relative to the central longitudinal axis of the unit. The brush can be located in front, in the middle or behind the car, and there is no fundamental difference in its location that affects the quality of cleaning. Such machines are used mostly on suburban highways, in-yard areas and as snow blowers.

Harvesting

These machines are equipped with a ploughshare blade mounted on the chassis, raking large and medium-sized mechanical debris to the roadside. The unit does not have brushes, therefore it cannot be used as a sand and dust cleaner. Such machines are often used as snow removal equipment or when raking fallen and wet foliage to the sides.

Sweepers

These mechanisms are multifunctional devices that are capable of sweeping and removing debris, as well as removing it from the roadway. These units are classified according to two criteria: by the method of garbage disposal and by the method of unloading. According to the first criterion, devices are divided into two categories.

Vacuum cleaning

Such models are equipped with vacuum pick-ups and a pneumatic system for transporting swept debris into the tank. The units are capable of operating at high speeds and are characterized by high productivity. This is due to the fact that they do not depend on the speed of interaction of the brushes with the road, but act like a vacuum cleaner. The only drawback of vacuum cleaning models is the high power consumption of the process, which, however, is a drawback of all vacuum devices.

Vacuum sweeping units, in which sweeping brushes are used in conjunction with a vacuum pick-up, can also be classified in this category. Such machines have a very high cleaning quality, due to the effective supply of debris to the suction device, carried out by means of brushes. In addition, models with vacuum debris collection are often equipped with an additional nozzle designed to suck up debris from trays, gutters and from under curbs.

PUM with mechanical waste collection

They load the dregs into a container using a belt or chain-scraper conveyor. Some models are equipped with a one-stage transport system, in which the garbage is fed into the tank using the reverse sampling method directly from the bristles of the brushes. Such units usually have a not very capacious hopper (with a capacity of up to one cubic meter) and are subject to rapid wear of the brush bristles. Also, mechanical collection of debris can be carried out using a paddle thrower and a belt brush. However, the latter method is not very reliable and is not used very often.The advantage of units with a mechanical garbage supply is the high quality of cleaning and a simpler device in comparison with vacuum models.

The second feature by which PUMs are classified is the way they are unloaded. According to this criterion, there are three categories of devices.

- The first includes machines in which unloading occurs by gravity, that is, when garbage is poured out of the container under the influence of its own weight and gravity. To do this, it is enough to open a special hatch or latches.

- The second category of devices is represented by machines with a tipper type of unloading, in which the tank tilts to one side and dumps its contents out.

- The third category includes models with a forced unloading system, in which the debris is squeezed out of the tank by a special damper powered by a mechanical or hydraulic drive.

Popular models

The modern market of harvesting equipment is represented by a large number of both Russian models and foreign samples. Domestic enterprises specialize in the production of units mounted on the chassis of trucks, tractors and cars. All PUMs made in Russia are produced strictly in accordance with GOST, they are distinguished by their reliability and long service life. The disadvantage of domestic models is considered to be low energy efficiency, which cannot be said about foreign models.

In this regard, recently, joint units assembled on the basis of Russian chassis, but using foreign cleaning equipment, have become popular. Such models have incorporated the best operational properties of Russian and imported equipment.

Below are a number of machines that are mentioned on professional forums more often than others, and therefore are in high demand.

Mini model Profi CS-M5

The compact mini model is a combination sweeper. It is designed to clean the area from snowdrifts, fallen leaves, debris and dirt. The unit is equipped with sweeping brushes up to 80 cm wide and a snow blade of the same dimensions. Replacement of attachments is carried out according to the instructions and does not cause any difficulties. In addition to tidying up, the machine can perform a variety of agrotechnical functions, such as tillage and loosening of the soil, removing weeds and mowing grass. The weight of the combi machine is only 53 kg.

Agata

This PUM is designed to remove and collect contaminants. It is equipped with a dampening system and a side brush for sweeping debris from under the curbs. The unit can be used as snow removal equipment, it is attached to the tractor with a three-point linkage system. Thanks to the adjustable drawbar, the device can be hinged on both the front and the rear. The machine is equipped with a disc brush, hydraulic drive, and has a trash can. Unloading takes place by tipping the tank using hydraulics. The weight of the model is 400 kg, the recommended speed is 6 km / h.

"Chistodor"

The "Chistodor" sweeping unit is presented in the form of an elevator machine with mechanical collection of garbage and its subsequent shipment to the back of a truck. The unit is used for cleaning large public spaces, highways and airstrips. He is capable of continuous work for many hours. The optimum speed of the device is 25 km / h, the productivity per shift is 180,000 cubic meters of waste. The weight of the unit is 3850 kg, the working width is more than three meters.

Broddway

Broddway's Swedish models are among the finest examples of sweeping equipment. The units are compatible with almost all Russian trucks and tractors, they can remove up to 1.2 tons of garbage per minute. The working width is 1.7-3 m, the optimal speed is 20 km / h.

"Puma"

The Puma trailed model is designed to work with the MTZ 80 (82) tractor.It is capable of collecting 38,700 cubic meters of garbage per hour. The sweep width of the brushes is 2.5 m, the capacity of the dustbin is 1.8 m3. The unit is in high demand, often purchased by road and public utilities. The model is produced at the Kemerovo Experimental Repair and Mechanical Plant.

See the next video for more details.

The comment was sent successfully.