How to use the tile cutter?

A tile cutter is a tool without which a tile would have to be cut with improvised means, risking spoiling many of its fragments. In the simplest case, a tile cutter would be replaced by a grinder, but not every master can cut perfectly even tiles and tiles.

How to work with a manual tile cutter?

Before using the manual tile cutter, test it for proper functionality. All its components, ideally, have no visible defects acquired in work, as well as factory defects. The home roll cutter works without roll jams. The surface of the roller normally does not have notches, dents and chips, its shape looks correct - it is always round, without distortion. The carriage moves without slipping or jamming.

To exclude wobbling, rolling of the roller, a ball bearing set is fixed on the rotating shaft - on both sides of the tool. The frame of the tile cutter should not be deformed, corroded by rust to noticeably thinning of the steel walls, and so on. Finally, both the roller and the bed must not be dirty before starting to cut tiles and tiles.

The step-by-step process for cutting a tile or tile is as follows.

- Mark the surface of the tile with a construction marker or pencil - according to pre-selected dimensions.

- Position the tile fragment on the tool frame so that the cut line overlaps with the cut line of the carriage assembly with the cutter wheel. Make sure that the distance from the cutting line to the extreme edge of the tile or tile fragment is 1 cm or more. Otherwise, the cut will turn out with chips - at least it may turn out to be with undercut sections, but it also happens the other way around: chips capture excess sections, and the fragment may be damaged.

- Drag the carriage part along the cut line with some effort. The main thing is not to overdo it: the glazed surface of the fragment must be cut to the full thickness. You cannot repeat cutting twice or more times - the cut will not be ideal.

- Turn the handle of the tile cutter so that the tool is ready for use again. Apply strong pressure - the unnecessary part of the fragment will break off evenly.

The ceramics are kept in water before cutting. Using a few drops of industrial or motor oil, apply along the cut line. This will prevent the scattering of small fragments, ceramic dust in different directions.

The manual tile cutter has a significant drawback: it is not recommended to work with thick and especially hard tiles - use a motorized tile cutter.

How to cut tiles with an electric machine?

Using a motorized tile cutter to cut floor tiles is a must. The instruction manual for this method allows you to get even edges even with a significant thickness of tile fragments - 2-3 cm. A clear difference is the absence of too sharp edges after cutting hard and thick tiles. The distance from the edge of the tile fragment to the cutting line reaches 4 mm - you do not have to worry about the possible unevenness and mess of the new edge.

The step-by-step guide is as follows.

- Mark the pieces to cut, place one on the cutting stage along the calibrated guide.

- Before switching on the diamond cutter, water cooling is activated at the cutting point. Then slide the piece towards the spinning disc.

- Do not overdo it - the pressure on the diamond disc from the side of the fragment should be small. Excessive force at the beginning of cutting can lead to cracks and chipping of the fragment. At the end of the cut, reduce the effort to the same low level - haste will lead to the appearance of chips on the fragment.

- When finished cutting, stop the disc and water cooling.

The fragment is cut. Move on to slicing the next one.

Useful Tips

Wavy, embossed tiles have variable thickness. In contrast to the simpler one - smooth, textured - this tile has a significant variation in thickness. You can cut it from the back side, by sawing as much as possible - through most of the thickness of the material - the processed fragment. Then, using a jigsaw with diamond-coated files, carefully, so as to prevent unnecessary chips of the glossy coating, which has increased strength, is cut through the same fragment.

It is strictly forbidden to break in the opposite direction such a fragment filed from the seamy side - the scrapping will turn out to be uneven, and the drawing will be damaged.

Embossed and corrugated tiles can be cut from the front using a grinder. Try to make cuts of the same (at the same level, in a specific layer of the entire thickness of the tile) depth. Tiles of variable thickness, having sharp, rather than smooth, drops, can also be cut with a tile cutter, but here you have to crush the decorative layer (relief) into dust along the notch line until the difference in the depth of the cut linear recess disappears, visually it is easy check. Then the tile breaks at an acute angle - along the furrow that the master drew.

If the furrow depth is the same on the waves of the cut made and the actual residual thickness of the uncut material - relative to the reverse side - repeats these waves, relief features, then it may not work to break evenly and smoothly cut tiles. The main principle is that the thickness of the residual layer for any surface relief of the tile must be the same, otherwise chips will form on the fracture.

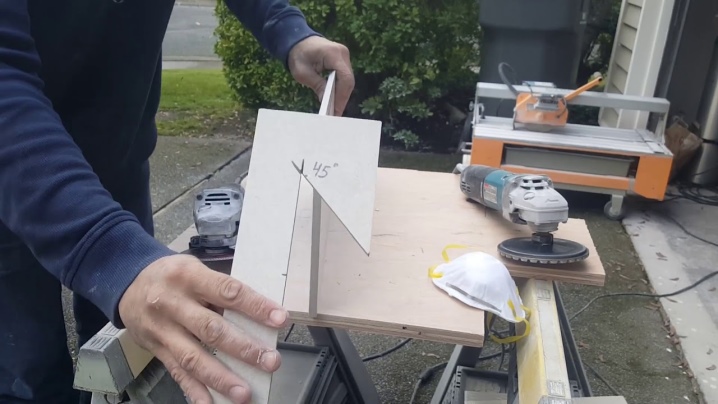

Sawing the tiles at an angle of 45 degrees requires a special tile cutter that allows an adjustable tilt relative to the platform on which the tile fragment is placed. The goal is to obtain a seamless (and without the use of overhead metal corners) convergence both along the outer and inner corners at the place where the two walls converged. Not all manufacturers make such a cut of the side edge (side) of the fragments, so it is better to take care of it yourself.

If we are talking about sawing at an angle of 45 degrees along the surface, then it is advisable not to break off the sawn fragment along the cutting line, but to saw it using a saw machine, which can be made on the basis of a grinder fixed on a small platform. Tiles made of any material, including ceramics, are cut using diamond-coated discs.

It is not recommended to break a beautiful tile with the help of improvised tools - pliers, gable cutter, and also cut it with a grinder using standard abrasive discs designed for cutting steel. In the first case, you will get uneven scrap, which would still have to be leveled with a saw machine. In the second case, the consumption of discs for metal would be very high, since corundum and fiberglass, from which they are made, are not intended for sawing ceramics and porcelain stoneware.

You can try to cut the tile with a pliers tile cutter, as well as saw it with a grinder, but pliers, nippers and simple tongs are not suitable here.

Cutting tiles with a power tool is a dusty job. To prevent the formation of excess dust that cannot be breathed, dampen the cut area with water. Motorized tile cutters are equipped with a water spraying system, in the case of using a grinder, the master applies water independently - from a hand sprayer, periodically stopping the sawing process.

In any case, it is not recommended to use a motorized tile cutter without a respirator. - drying out from heating when the disc friction against the material, the tile immediately begins to give a certain amount of dust. The manual cutter may require wetting the glossy surface with oil (instead of water) - along the cut line. This prevents the scattering of high-speed debris, striving to get into the eyes, when the master used not fully closed glasses with a panoramic visor.

For information on how to use the tile cutter, see the next video.

The comment was sent successfully.