What are pipe dies and how to work with them?

To make the work process easier, you always need the right tool. In order to leave a thread on the pipe, different techniques are used. But most often they use a die. A tubular die is a metal structure used to thread a pipe. This is done by twisting the die on the pipe. Consider the main types of pipe dies, as well as their size range.

Description and purpose

For many, it is no secret that almost all instruments or their analogs appeared in antiquity. Most often, the origins go back to Ancient Rome, when jewelers needed to create new jewelry, and artisans - new weapons or tools. Since the nuts were invented much later, they tried to somehow connect all the parts together. Therefore, it was popular to hammer one detail into another. And only gradually, by trial and error, it became clear that twisting one element into another is much easier and more practical when parsing.

After that, work began on a tool that could chisel one of the surfaces. It is not known for certain who was the master who made the dies as they are now. But around the 17th century, the first such designs for threading began to appear. In shops and repair shops, it is very common to encounter the need to use a pipe die, mainly to combine two parts without welding. In appearance, the die looks like a very large nut.

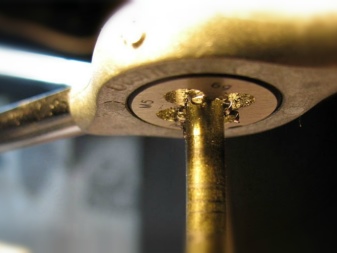

It is round in shape, and inside there are special central holes with a cutting edge, which leaves notches.

The hem includes turns. There are approximately 8 to 10 of them. The first two turns are sharper and refer to the intake part. Further, in addition to the central hole, there are also smaller holes. They are intended in order to pass the formed metal shavings during operation. Their number varies from 3 to 6, it all depends on the configuration of the tool and its purpose. Tube dies are made from high speed steel, less often from harder alloys. The purpose of the tool is to manually apply a thread to a specific section of the pipe. Used for sharpening various bolts, screws and pipes that have different diameters. For the convenience of determining the size, the size marked with the letter "G" is most often engraved on the die body.

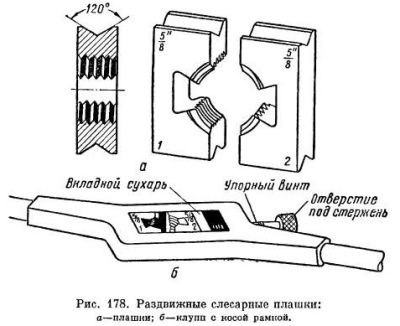

Those who have been familiar with the tools for a long time and actively use them know that a die is sometimes called a different name - a stick. But there is a slight difference between them, although, in fact, they perform the same function. If the die looks like a nut with axial holes inside that form an edge, then the die looks more like plates with holes and grooves, most often of a small diameter. And only a knowledgeable master will be able to distinguish between these two devices.

Now even sellers in stores call both items a die, and they cannot explain any difference between them.

Views

There are a large number of different types of pipe threading dies on the market today. Each of the presented models has its own characteristics and advantages, but there are also nuances in working with them. V Basically, all dies are classified according to different criteria.

By housing design

Such dies are also divided into several types.

- Solid or round. This is a cylindrical die that completely captures the part around it, tightly fitting to the product (it is important to choose the desired diameter). A very precise and high-quality thread is obtained due to the firm grip.

- Split die. Its peculiarity is that the required cut will be made transversely. Therefore, the reliability of the twist in this case drops by several percent due to the loose fit of the two parts to each other. Deviations from the norm are insignificant, in the range of 0.1-0.3 mm. Ideal for connecting two parts, which will then not be accentuated by any emphasis.

- The sliding plate consists of 2 parts. They are connected to each other, and a part is inserted into the space between them. The peculiarity of this design is that there is no limited diameter in it, which is very convenient, especially for beginners.

Most often, the round is considered the most popular. lerka... It is easier to use and the result is suitable for any job. The process itself takes place in one movement, and not in several stages, as with the same sliding dies. Such cylindrical dies are threaded with different pitches, which greatly facilitates the work. And they also make inch carving. It is customary to single out only one drawback - the working part of the round scraper does not lend itself to grinding. Split dies are used to correct the thread diameter. For example, if it is necessary to replace part of the water supply pipe, but there is already a thread there, then it is best to use this type of die.

Indeed, in fact, the resulting notches can be of various shapes: round, rectangular, triangular or even trapezoidal. And also the dies are usually subdivided according to directions. With the right direction, the thread is applied to the right, that is, clockwise. Most often used for studs, screws or bolts. It is the right direction that can be found on almost all products. The left direction applies the threads to the left.

It is used for restoration work. For example, for left-hand pins or rotating mechanisms.

By form

Dies are divided in shape into several types:

- tubular;

- round;

- hexagon;

- square.

Dimensions (edit)

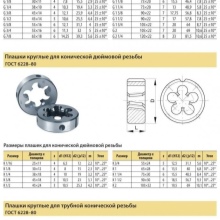

Each tool or hole has its own standard. There is also GOST for dies. All markings must comply with these parameters. As mentioned earlier, the rake is more often presented in the form of a nut, which includes an edge and a chip outlet. The thread pitch can vary from 8 to 10. The pitch is the gap between the threads. A specialized device was created for measurement - a vernier caliper. It is used if it is necessary to select a die for an already existing size. The size range of dies is measured in inches. For example, 2 inches equals 1/8 mark.

But if there is a specific pipe, how do you determine which diameter or inches are needed? For this there is GOST. After all, the pipes are performed just in these criteria. For example, if a pipe with a diameter of 20 mm, then according to the standards we are looking for approximate parameters, that is, 21.74 mm. Hence, the nominal diameter will be 5/8 inches. It will be the same for a pipe of 25 mm (corresponds to 3/4) or 32 mm (corresponds to 1). The data will need to be looked for in a special table, which can be asked even in the store. You can simply tell the seller the desired pipe diameter or thickness.

But what if there is only the size of the die, and how to find out correctly for which pipe it is suitable? The principle works the same here. For example, if there is a 1/2 inch stick, then a 19.79 mm pipe corresponds to it. Memorizing all these subtleties is useless. Thanks to the standards, you can easily find the required dimensions. And also on the plate there is a special marking with letters. This is necessary in order to know exactly for which type a given thread is needed. For example, M10 marking. The letter "M" here is an abbreviation for "metric yardstick". Cutting type - triangular profile, diameter range from 1 to 76 mm.“M10” is the designation for 10 mm metric threads.

Tube dies are designated by the English letter "G". The letter "K" belongs to the pipe tapered, and is used for taper threads. Most often it can be seen in fuel lines.

The peculiarity lies in the fact that the thread is one-sided, and the cone is located at an angle of 30 to 55 degrees.

Features of use

In order to use the plate correctly, you need to study it. Find the size, markings and type of thread. This will help in the future not to make mistakes and to organize the work correctly. It is also necessary to remember what type of thread is needed - right or left. It is best to prepare both the lerk and the pipe before use. You must first remove the chamfer or paint from the pipe. Then a lubricant (any oil) is applied to the surface. Next, the die is fixed with a die holder, or a special wrench is selected.

The lerka is brought to the beginning of the pipe and carefully fixed. In the process of work, the structures must be attracted to each other so that resistance appears, and the die, indeed, left notches behind. It is recommended to twist not only in one direction, but to do several turns forward and half a turn back... This will be enough to secure the thread. To check the result of work, a nut of the same diameter is simply tightened on the pipe. If the nut tightens without difficulty, while not missing anything (this is especially important for water or gas pipes), then the work can be considered complete.

The comment was sent successfully.