Everything you need to know about the bulk density of sand

During the construction process, a large number of different materials are used, one of which is sand... It is used as a basis for mixing cement-sand mortar, for arranging a sand cushion of the foundation and other construction processes. A wide range of applications became possible due to the physical and technical characteristics of this bulk material, one of which is the bulk density.

What it is?

The sand must be of high quality. The outcome of the entire construction depends on this. Its quality can be determined only on condition that all its characteristics are taken into account, such as the coefficient of radioactivity, filtration, fraction and, of course, bulk density. This is the name of the physical quantity, which is equal to the ratio of the mass of sand to its volume. Like all other parameters of bulk material, this one is also determined and controlled by state regulations, namely GOST 8736-93.

Standard unit of measure Is kilogram per cubic meter (kg per m3), but tons can also be used. The unit of measurement of a physical quantity is influenced by the amount of volume.

Despite the fact that there is a definite formula by which this physical quantity is determined, it is rather difficult to obtain an exact value, even after laboratory tests. The thing is that the ideal compaction of sand is possible in the natural conditions of its occurrence. That's why to obtain at least an approximate parameter, it is customary to use a special coefficient.

After a number of laboratory tests, it was found that the average coefficient of the bulk density of sand is from 1400 kg / m³ to 1800 kg / m³. This information is clearly spelled out and controlled by GOST.

Influencing factors

Many people wonder why the value of a given physical quantity of bulk material is not constant. The thing is that there are certain factors that affect its formation.

- The value of the sealing factor. Loose material, which consists of the smallest particles, is also characterized by the presence of air. Air gap, its volume depends on the level of pressure on the material.

- The place where this bulk material was located. There are several mining methods. For example, sand that is obtained by washing out of water has a higher bulk density than that extracted from a quarry. But the greatest indicator in this case is sand, which is obtained by artificial means. This is due to the fact that the process of creating an artificial material is completely mechanized, and the possibility of the formation of an air gap is minimized.

- The value of the coefficient of voidness of the sand. The smaller it is, the higher the bulk density. To obtain the desired indicator, the material is compacted using special equipment before use. During the compaction process, vibration occurs, under the influence of which the sand begins to sag, thereby removing air.

- Fraction. There are small, medium and large. With this factor, everything is very clear. The smaller the particle size of the material, the tighter they adhere to each other, as a result of the decrease in the number of air spaces and the increase in bulk density. But the sand of the largest fraction is characterized by a low coefficient.

- The origin and parameters of the rocks that are in the composition of the sand. Pure sand cannot be found anywhere else.It contains completely different minerals: quartz, mica, clay. Each of them has certain physical and technical parameters. This affects the bulk density of the material itself. But truth be told, mineral composition is the last factor to look for when determining density values.

- Moisture coefficient of bulk material. This is the determining factor. The more moisture a material contains, the higher its bulk density. Experts say that the bulk density of wet sand is 30% higher than that of dry material.

Each factor that was mentioned above must be taken into account. In the case where sand is used in the construction of facilities, its bulk density is checked immediately before use.

Density of different types of sand

Currently, due to the fact that there are many different equipment and equipment, it has become possible to extract sand from a variety of places of its occurrence. They determine its type and characteristics.

- From the river bottom. This type of material, taking into account the opinion of experienced craftsmen, is of the highest quality and is suitable for construction. It is used for mixing cement-sand mortar of a high quality level. It is characterized by minimal voidness, different mineral composition. Bulk density of dry river sand varies from 1450 to 1700 kg / m³, and wet - from 1780 kg / m³ to 1870 kg / m³.

- From the seabed... Sea sand is not very clean, as it contains organic matter, including salt. In most cases, before use, especially if the material is used to prepare a mortar, it is additionally cleaned and filtered. It is characterized by high bulk density - from 1550 kg / m³ to 1750 kg / m³.

- From quarries... Quarry material consists of clay, stones, soil and other materials. There can be absolutely any faction. It has a bulk density of 1700 kg / m³ to 1850 kg / m³.

- From rocks. This is the lowest quality species. Its parameters and properties are not very good, so it is rarely used. The bulk density of rock sand is one of the lowest and averages 1450 kg / m³.

There is another type of sand - artificially created. It is obtained in the process of crushing rocks. Therefore, it contains quartz, expanded clay. It is characterized by a high bulk density - from 1670 kg / m³ to 1750 kg / m³.

Definition and calculation

Why do you even need to determine the bulk density of sand before using it? This physical and technical parameter of bulk material makes it possible to determine:

- with the scope of use of the material;

- with the required amount of bulk material mass that will be needed to perform a certain type of work;

- with the required level of ramming.

The most important thing that will help determine the bulk density of bulk material is its quality.

Earlier in the article, we talked about the fact that to determine a more accurate value of the bulk density, the so-called sealing coefficient is used, the value of which depends on the condition of the sand embankment and the type of work:

- for dry sand mixture - 1.05-1.15;

- for wet material - 1.1–1.25;

- for backfilling of pits - 0.95;

- for filling the sinuses - 0.98;

- for the arrangement of engineering networks along railways and highways - 0.98–1.0.

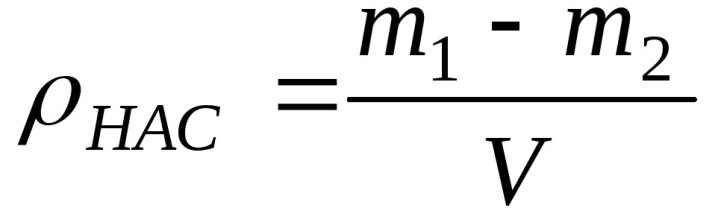

The bulk density of the material can be determined independently. To do this, you do not need to have a special set of equipment that is used in the laboratory. There is a certain formula, the application of which makes it possible to determine a given physical quantity using available means.

Bulk density of bulk material is determined by the formula:

P = (m1 - m2) / V, where:

m1 is the total weight of bulk material, which is placed in a measuring container, for example, a bucket;

m2 - tare weight;

V is the volume of the container, for example 10 liters.

Before proceeding with the calculation, all values must be converted into m³: 10 liters is 0.01 m³.If this value is converted into kilograms, then we get 0.56 kg. A full ten-liter bucket of sand weighs approximately 15 kg. Knowing all the quantities, you can use the formula:

P = (15 - 0.56) / 0.01 = 1444 kg / m³.

In order to obtain a more accurate result, the obtained value is multiplied by the compaction factor. But it must be remembered that this correction factor has an error of about 5%. Before using the material, it is advisable to calculate the value several times, each time picking up sand from different areas. This need arose because bulk material that is stored under certain conditions may have different levels of moisture.

In the next video you will see a demonstration of the virtual laboratory work "Determination of the bulk density of a material".

The comment was sent successfully.