All about quarry sand

Quarry sand referred to as a loose rock. From the material of this article, you will find out why it is in special demand, how it is mined, how it differs from the river and what happens. In addition, here you will find information about its varieties and areas of application.

Composition, properties and characteristics

The quarry sand contains feldspar particles, quartz, mineral fractions and mica. Depending on the type of quarry, it can differ not only in composition, but also in structure, and even color... The shade depends on the mineral composition. Most often it is yellow, although the shade can be different (up to dark amber).

The sand fraction is different. It is uneven, rough and porous. This explains the reliability of the cement bond. However, the density of kg per m³ may vary. By its origin, it differs from the sea, river and artificial. The key characteristics of quarry sand are as follows:

- specific gravity;

- bulk density;

- environmental friendliness;

- humidity;

- the volume of suspended matter in percent.

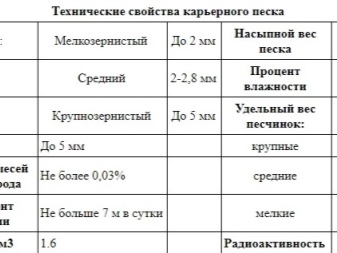

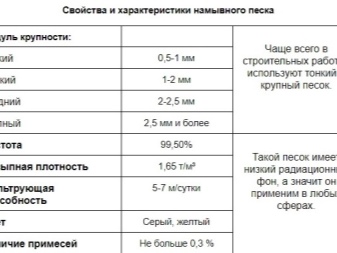

Depending on the deposit and variety quarry sand fraction varies in the range of 1.5–5 mm. According to this parameter, the varieties are divided into small-medium and large-fraction species. Particle size determines the type of use and is especially relevant for mixing with cement. Fine fraction sand with a particle size of up to 2 mm is considered. Medium-grained sand is slightly coarser: its particles reach 3 mm. If the grains of sand are larger, the variety is called coarse-grained... The size modulus is a criterion that determines the weight of 1 cube of sand.

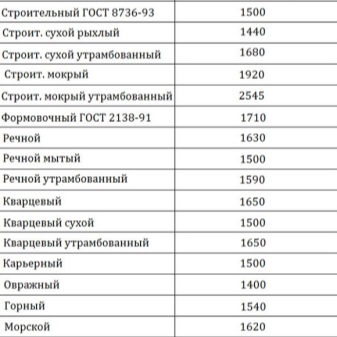

Density extracted material is true and bulk. The first is nothing but the density of the fraction itself. It is 1.5-1.9 times larger than bulk. According to the approved GOST 8736-2014, it can vary within 2–2.8 g / cm³.

Ideally, it should be equal to its specific gravity.

Bulk density - an indicator, the calculation of which implies taking into account all fractions present in the sand (including air filling the space between the grains). In production, construction and other areas, it is this indicator that is important. Based on the particle size, this parameter can be 1400-1800 kg per cubic kilogram. This parameter is determined by the weighing method, in which cylindrical metal containers of different volumes are used.

Smaller containers are used to measure the density of dry and already cleaned sand. If you need to weigh unrefined material of natural moisture degree, use a large container. Moreover, in the course of execution, not only filled, but also empty containers are weighed. True density determined in two ways: by means of a pycnometer and by means of a Le Chatelier device. Concerning volume of impurities, then this characteristic can be both a plus and a disadvantage of natural material. For example, clay components improve the properties of sand used for mortars.

Due to suspensions, shrinkage is excluded, the ready-made mortar becomes elastic and mobile.

The maximum allowable amount of organic matter can reach 3%. Sulfur and sulfides should account for no more than 1%. Concerning humidity, then this characteristic determines the weight. The more moisture in the sand, the heavier it is. According to GOST, the moisture in the sand should not be more than 7%. Purity sand is one of its key characteristics. Filtration degree - no less significant indicator. For grains of quarry sand, this coefficient varies within the range of 0.5–7 m per day. It depends on the type and amount of impurities, as well as the size of the particles themselves. The main technical properties of quarry sand can be found in the table.

Radioactivity parameter is determined by the type of deposit. More radioactive is the variety obtained from mining. It is categorically impossible to use it in the construction of residential buildings. The radioactivity class for such an application should be the first. 2 and 3 are suitable for road construction.

Specific gravity quarry sand varies. If it is a fine-grained variety, 1 cube weighs approximately 1700-1800 kg. When the fraction is medium or coarse, the amount of kg / cube decreases. On average, this figure can be 1.5–1.6 tons / cubic meter. However, humidity can also be a decisive factor. For example, if it varies from 5 to 7%, the weight of 1 cube of sand can increase to 1.8 tons.

However, the weight of one cube may depend on the level of compaction. For example, it can be the natural state of the underlying sand or artificial compaction (compaction), as well as a bulk version of the sand mixture. The larger the seal, the greater the weight. Both the specific gravity and the density increase due to the fluid. For this reason, buying sand in winter is not recommended.

The weight of the cube is of particular importance because it is used in calculations prior to planned work. Grain composition it is dolomite, limestone, feldspar, quartz, quartz-mica. When buying, the seller indicates a number of indicators in the attached quality certificate. For example, tabular data contains information about the percentage of natural moisture, bulk and true density, voidness. In addition, the table indicates the size modulus, the content of the coarser fraction, dust and clay particles. And also the presence of organic suspensions, color, filtration coefficient and specific efficiency of natural radionuclides are noted.

Depending on the form of the passport it indicates not only actual indicators, but also standards in accordance with GOST. In addition to quality indicators, the passport may have marks for grain composition. The hole diameter of the sieves is indicated here, as well as the partial and total residue in percent.

If the specific gravity is not equal to the density, this means that it is wet, of poor quality, or simply not tamped.

Extraction features

Usually, a quarry sand deposit is located under a layer of soil at a shallow depth. It is mined from the bowels of the earth through quarrying... Methods of mining are considered cost-effective; they use bulldozers, excavators, dump trucks in their work. The most popular open method, it is cheaper than the others and practically does not use explosives. Its use is justified when there are no other ways to open the upper layers of the earth.

If the quarry is flooded with water, the technology is complicated by the use of a pump. It unloads sand from the bottom, while the sand passes through the so-called slurry, which is a filter for loose rock. During the passage through the channel, moisture is returned back to the quarry. This mining method is more expensive, it is called hydromechanical. According to other mining techniques, other special-purpose mining equipment may be used. For example, sometimes the technique allows the use of a special sieve that sifts out clay and stones. The mesh cells used may vary in size. Purification of sand from extraneous fractions is not only mechanized, but also combined.

Comparison with river sand

Despite the fact that quarry sand is often confused with river sand, they have several differences. For example, they have different density and size of grains of sand.For river sand, they do not exceed 0.5 mm. This type is used in drainage systems and when creating a cement screed. The scope of application of quarry sand is more extensive, besides, the methods of extracting the river variety are more costly. The key difference is also the purity of the formulation. River sand has practically no foreign inclusions, while quarry sand has them, and in different volumes (sometimes this percentage ratio can reach 1: 9).

In small proportions, this is insignificant, but the presence of organic matter can cause the fermentation of the mortar. In other words, if the quarry type of sand is not cleaned, it will be unsuitable for use in various applications. Differs in two types and type of faction. Due to the constant influence of water, river grains of sand are smooth and roundish. This can affect adhesion to building materials. The price of river-type material also differs: sometimes it is one and a half times higher than the cost of the sand extracted from the quarry. However, if the product of the second type has undergone high-quality processing, it will exceed the river type in its characteristics.

In addition, there is less river sand in nature when compared with quarry production. The advantage of the latter is the greater availability of transportation.

Applications

Due to its characteristics, quarry sand is used in various fields. For example, it applies in construction, it is used in the arrangement of territories, the creation of asphalt concrete mixtures. Despite the low cost of mining, such material cannot be called universal, it is not suitable for all construction work. The more dust, clay and other suspended matter in it, the less its suitability in the construction industry.

As for the illiquid variety, such sand purchased for dumping roads, trenches and ditches. With his help improve soil composition... A variety with a large grain size is often combined with crushed stone. Large fraction type is applicable for filling swampy areas of land, as well as flooded lowlands.

Quarry sand has found application and at home. It is used to create pedestrian walkways. A small layer of material allows you to protect yourself from ice in winter. It is also an excellent material used in agriculture and horticulture. It is a component of nutritional mixes used by gardeners and gardeners. It is added to the soil, used for growing seedlings. It is used to preserve the harvested crop (it is in it that the harvested vegetables are stored).

Quarry sand has filtering properties. Thanks to this feature it is a means of cleaning equipment in sewage treatment plants... It is also used in cases where it is necessary to level the site before laying the foundation. Some varieties, due to their composition, are used in the glass industry.

Depending on the type of fraction and the degree of purification, sand is used for roughing and finishing work in the construction industry.... Some varieties are subjected to additional rinsing, after which they are added to the compositions of finishing putties, grouting and other finishing and decorative materials. The same type of material is used in the manufacture of flooded floors. It is durable and durable. It is used and for playgrounds with sandboxeschoosing the most environmentally friendly and harmless option. In addition, it applies when creating flower beds, as well as when decorating them... It is used for landscaping adjoining territory.

In addition, it applies for finishing facades. Moreover, depending on the size of the fraction and the type of decorative material, it can imitate the texture of different materials, be it the so-called "fur coat" or "bark beetle". It is for sale in small and large batches. The price per kilogram today varies from 170 to 400 rubles per 1 cubic meter.In addition, quarry sand is sold in 50 kg bags.

The product is accompanied by a certificate of conformity indicating the size of the fraction, the purpose of a particular variety.

Species overview

There are several types of quarry sand. According to the method of processing, each type has its own characteristics and differences. Each type has its own purpose. All types of material are mined by licensed enterprises, which, even before the start of work, submit estimates and plans for the development of quarries to government agencies. According to the type of processing, sand is washed, seeded and unpaved.

Alluvial

This type of sand is mined by means of hydromechanical devices. By using the water rinsing technique, it is possible to rid the sand of foreign suspensions. This species is distinguished by its purity, it is washed several times. It does not contain harmful components and various suspensions, they are removed immediately during extraction.

This type of sand is used in the production of concrete and bricks, reinforced concrete products. With its help, they build highways, they buy it for the construction of buildings for various purposes. This is a high quality type of material. It is mined from flooded deposits, washing out impurities and even dust.

Seeded

The method of extracting seeded sand is different. It is considered extremely simple. In this case, the technique of technical and mechanical sieving is used. In the course of cleaning, equipment with a mass of sieves and cells is used. As a result, large fractions and stones are removed from the total mass. A fine-grained product of this type is used in the manufacture of plaster mixes and mortars.

This is an excellent material for casting a foundation (for a pillow), it is indispensable when mixing masonry mortars. In its structure, it is very soft, in addition, it is practically weightless.

Sandy

Open pit sand is classified as a less pure variety. The content of foreign inclusions in it can reach 40%... Because of this, it is not suitable for finishing work, it is more often used as a trench filler and for leveling land plots. This is a low quality draft.

However, it is actively used in utilities and agriculture. It is he who is used in winter for sprinkling on ice. It is also used as a way to preserve vegetable crops. But it is not suitable for either concrete or cement mortars. Its impurities impair performance.

In the next video you will find interesting information about the extraction, delivery and application of quarry sand.

The comment was sent successfully.