Varieties and selection of sand for concrete

There is an opinion that it is not very difficult to choose sand for a cement mixture. But this is not so, because there are several types of these raw materials, and much depends on their parameters. Therefore, it is important to know what kind of sand you need to use to make mortar for various types of construction work.

Why is it needed?

Preparing the best quality concrete mix will be a difficult task, but without this, not a single construction takes place.

To begin with, we will list the main components of the cement mortar used in construction work. These are water, cement, sand and gravel. All of these ingredients are designed to perform specific tasks. If you prepare a solution from one cement diluted with water, then after drying it will begin to crack, and it will not have the necessary strength.

The main purpose of sand in a concrete solution is to provide additional volume and envelop the second filler (crushed stone, gravel), taking up space and forming a mixture.

Among other things, the presence of bulk materials in the solution significantly reduces its cost.

The strength of the monolithic filling and repair work largely depends on the properties of the solution. The sand will be useful only if it is correctly selected and there is not too much or too little of it. When there is too much of it in the solution, the concrete will turn out to be fragile, and it will easily crumble, as well as collapse under the influence of atmospheric precipitation. If there is not enough sand, then cracks or depressions will appear in the fill. Therefore, it is very important to correctly observe the proportions of the mixture.

Requirements

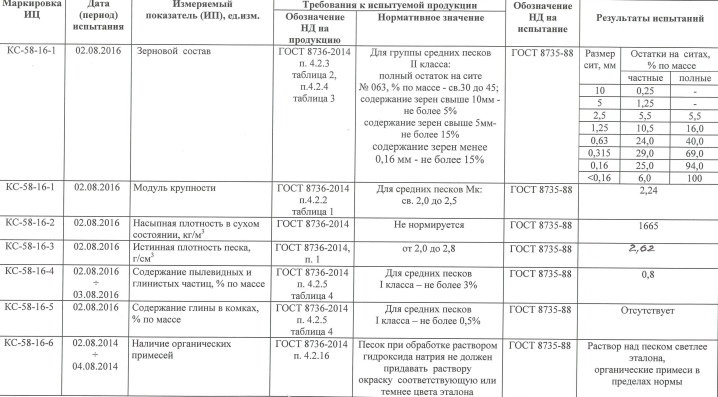

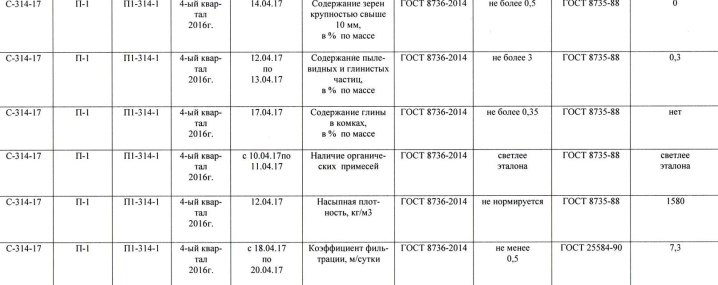

As with all components in a concrete solution, certain requirements are also imposed on sand. Characteristics of natural similar materials and obtained by crushing screenings (except for those made by grinding rocks) are listed in GOST 8736-2014. It applies to these components of concrete mortar used in the construction of various objects.

Based on the size of the fractions and the presence of impurities in it, sand, according to the standard, is divided into 2 classes. In the first, the size of the grains of sand is larger and there is no dust or clay, which negatively affects the strength of the solution and its frost resistance. The amount of impurities should not exceed 2.9% of the total mass.

This class of bulk material is considered a higher priority and is recommended for the preparation of cement mixtures.

According to the particle size, sand is divided into many groups (very fine, fine, very fine, just fine, medium, coarse and very coarse). Fraction sizes are indicated in GOST. But in reality, builders conditionally divide it into the following groups:

- small;

- average;

- large.

The second after particle size, but no less important requirement for sand is moisture. Usually this parameter is 5%. This figure can be changed if it is dried or it is additionally moistened with precipitation, respectively 1% and 10%.

It depends on the humidity how much water to add when preparing the solution. This characteristic is best measured under laboratory conditions. But if there is an urgent need, then this can be done right on the spot. To do this, just take the sand and squeeze it in the palm of your hand. The resulting lump should crumble. If this does not happen, then the humidity is more than 5 percent.

Another parameter is density. On average, it is 1.3-1.9 t / cu. m. The lower the density, the more in the sand filler of various undesirable impurities.

If it is extremely high, this indicates high humidity. Such important information should be spelled out in the documents for the sand. The best indicator of density is considered to be 1.5 t / cu. m.

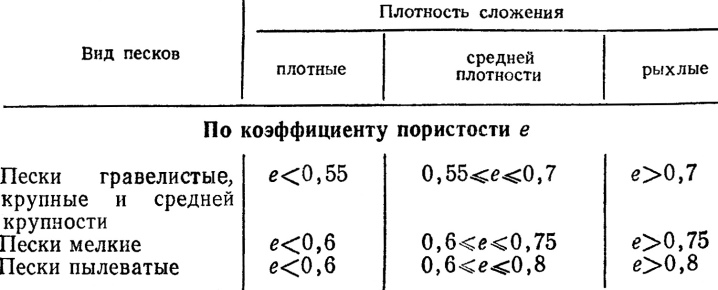

And the final characteristic to look out for is porosity. It depends on this coefficient how much moisture will pass through the concrete solution in the future. This parameter cannot be determined at the construction site - only in the laboratory.

All sizes of fractions, density, porosity coefficients and moisture content can be found in detail by studying the corresponding GOST.

Species overview

For the manufacture of mortar on construction sites, natural or artificial raw materials can be used. Both types of sand to some extent affect the strength of the concrete structure in the future.

By its origin, this bulk material is divided into marine, quartz, river and quarry.

All of them can be mined in an open way. Let's consider all types.

River

This species is mined in river beds using dredgers, which absorb the sandy mixture with water and move it to storage and drying areas. In such sand, there is practically no clay and very few stones. In terms of quality, it is one of the best. All fractions have the same oval shape and size. But there is a minus - during mining, the ecosystem of the rivers is disturbed.

Nautical

It is of the highest quality. In terms of its parameters, it is similar to a river one, but it contains stones and shells. Therefore, it requires additional cleaning before use. And since it is mined from the bottom of the sea, its price is quite high compared to other species.

Career

Extracted from the earth in special sand pits. It contains clay and stones. That's why it is not applied without cleaning measures, but its price is the lowest of all.

Quartz

Has an artificial origin... It is obtained by crushing rocks. Ground sand has practically no unnecessary impurities in its composition, since it is cleaned immediately during the production process. Although it is homogeneous in composition and purified, there is also a disadvantage - high cost.

Since sand is one of the elements of concrete, its viscosity depends on the size of the fractions: the higher it is, the less cement is needed to prepare the solution. This parameter is called the size modulus.

To calculate it, you must first dry it thoroughly and then sift the sand through two sieves, with different mesh sizes (10 and 5 mm).

In normative documents, the designation Mkr is adopted to denote this parameter. It is different for each sand. For example, for quartz and quarry, it can be from 1.8 to 2.4, and for river - 2.1–2.5.

Depending on the value of this parameter, bulk material according to GOST 8736-2014 is divided into four types:

- small (1-1.5);

- fine-grained (1.5-2.0);

- medium-grained (2.0-2.5);

- coarse-grained (2.5 and higher).

Selection Tips

To figure out which sand is most suitable, the first step is to find out what construction work will be performed. Based on this, you need to choose the type and type, while paying attention to the price of raw materials.

For laying brick products or blocks, river sand will be the best choice. It has optimal parameters for this task. To reduce the cost, it makes sense to add a sprinkle extracted from the sand cut, but here it is important not to overdo it.

If you need to fill in a monolithic base, then river sand with small and medium particles will be the most suitable for this mixture. You can add quite a bit of washed sand from the quarry, but it is worth remembering that the inclusions of clay are not completely removed from it.

If you need to build something especially durable, for example, the base of buildings or concrete blocks, then you can use marine as well as quartz bulk material.

They will give the products strength. Due to the greater porosity, water comes out of the solution faster than from other types of sandy raw materials.In turn, these types have worked well for plastering. But due to the fact that their production is difficult, then they will cost significantly more - and you need to know this.

Quarry sand is the most widespread and at the same time the most contaminated with various additives. It is not advised to look for an application for it when erecting any elements where special reliability is required. But it is perfect for laying under tiles, leveling areas for foundation blocks, creating paths in the garden. A huge plus is the low price.

Quantity calculation

If you take cement grade M300 or lower for the mortar and use fine-grained sand with grains less than 2.5 mm in size, then such a mixture is suitable only for arranging foundations for residential buildings, no more than one floor in height, or garages and outbuildings.

If there is a large load on the base, then cement of a grade of at least M350 should be used, and the size of the grains of sand should be at least 3 mm.

If you want to get the highest quality concrete, then the most important principle in its manufacture is the selection of the correct proportions between the main components.

In the instructions, you can find a very accurate recipe for the solution, but basically they use this scheme - 1x3x5. It is deciphered as follows: 1 part of cement, 3 parts of sand and 5 - crushed stone filler.

From all of the above, we can conclude that it is not so easy to pick up sand for a solution, and this matter must be approached responsibly.

About what kind of sand is suitable for construction, see below.

The comment was sent successfully.