All about dust-free sandblasting

Knowing everything about dust-free sandblasting is interesting for both ordinary users and workshop owners. It is imperative to figure out what dust-free devices are, and how to choose an installation with a vacuum cleaner. A separate important topic is specific recommendations for the use of such a device.

Advantages and disadvantages

First of all, you need to find out what is good or bad dust-free sandblasting in principle. This technique is characterized by excellent mobility and easy operation. Dustless sandblasting has a number of advantages:

-

will allow you to do without specialized cameras;

-

prevents clogging of surrounding objects;

-

makes it possible to get by with low-power compressors;

-

provides cleaning in the most inaccessible areas;

-

guarantees safe work without expensive and tedious protective equipment.

The disadvantages of the device include the following facts:

-

not powerful enough compared to the "dusty" models;

-

can only clean in narrow strips;

-

makes it constantly interrupt to empty the dust accumulators;

-

requires systematic replacement of nozzles (and even more frequent cleaning);

-

not suitable for working with perforated parts and surfaces with fine relief.

Principle of operation

Dustless sandblasting guns are used where dust emission is very dangerous or simply undesirable. With their help:

-

clean the metal from traces of primers and paints;

-

remove residual rust;

-

clean welded seams;

-

remove the decoration from stone elements and decor items;

-

prepare various surfaces for painting and basic grinding;

-

form patterns on glass (including mirrors), on metal.

Along with sand, crushed granite, expanded clay or cast iron shot (with a cross section of no more than 0.5 mm) can be supplied for work.

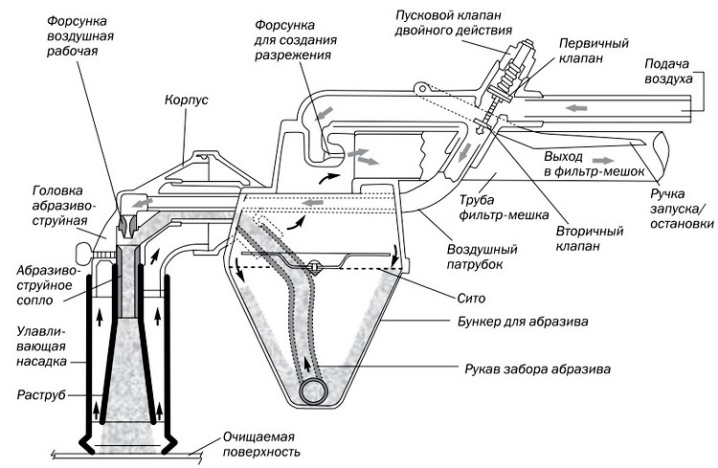

Dust-free processing is carried out due to the closed operation of the compressor. First, he pumps air into a special tube. It passes through the sand reservoir and carries the abrasive through the nozzle. When hitting a part, the sand bounces off. Then, through another pipe, passing around the nozzle, it returns to the previously abandoned tank. The cleaned abrasive can be used later, and dust and dirt are deposited in a separate container.

From there, they are usually thrown away by hand as they fill. Some models provide for removal through a special hose. The nozzle tip is equipped with a rubber nozzle. Due to its tight fit to the surface, it seals the device. Air leaks and dust emissions are absolutely excluded.

Varieties of devices

Sandblasting with a vacuum cleaner (dust collector) is quite widespread. It is an elongated bag in shape. It is attached from above inside the sand container. The dirt is carried there by the very air flow entering the inlet channel. Of the disadvantages of the scheme, it is worth mentioning the relatively limited power and the need to often stop work to empty the drive.

There is also sandblasting, in which dust-free operation is achieved through a limited consumption of abrasive. In this case, a gun with a special nozzle is connected to the compressor. A cloth bag is provided where the abrasive is collected. The delivery set always includes attachments.

This technique does the best job of cleaning out small nests of rust, but it cannot pretend to be anything more.

How to choose?

In the CIS, sandblasting machines under the Russian Master brand are very popular. Among their advantages are comparative simplicity and reliability. Almost any specialist will also pay attention to products:

-

Westers;

- Blastse;

- Clemco.

The Chinese brand AE&T has a very wide range of inexpensive sandblasting machines. But it is important to pay attention not only to the brand, but also to the practical characteristics. If you only need to deal with rust prevention in the garage and clean up local spots, you need to take a model with a limited abrasive consumption.

The same devices are recommended for use with individual cars and motorcycles. Large areas are much more efficiently processed by devices with a vacuum cleaner that can work for a long time; the power of the technique is chosen in accordance with the volume of the forthcoming manipulations.

Operating tips

Before starting the compressor, it is necessary to check whether all parts are well connected, whether the equipment is hermetically sealed. For a clear selection of the operating mode, it is useful to monitor the readings of the pressure sensors. The abrasive is taken in such a quantity and in such quantity as to precisely remove the rust, but not to destroy the material. Primary cleaning is carried out with a coarse fraction of sand.

A smooth surface is treated with a typical nozzle. Complicated preparation (covering objects) is not needed. The seals should be checked before and after each work session. Rust is removed by holding the tip at an angle of 80-90 degrees, and the paintwork - strictly at an obtuse angle.

And also we must not forget about wearing personal protective equipment.

For more information on dust-free sandblasting, see the video below.

The comment was sent successfully.