Strengthening floor slabs: rules and methods

All supporting and enclosing structures of buildings and structures lose their quality properties during operation. Not an exception - linear support elements (beams) and floor slabs. Due to an increase in the load on the structure, as well as partial damage to the reinforcement, cracking appears on the surface of prefabricated panels and in the depths of the concrete mass of monolithic structures.

To increase the bearing capacity and increase the service life, the plates are reinforced. The choice of a suitable method of strengthening the slabs is dictated by their design features.

Identifying the vulnerability

Often, damages inadvertently can be masked by suspended and suspended ceilings, plasters, paints, which does not make it possible to notice them in time and start working on repair and restoration.

When determining the actual technical condition of load-bearing and enclosing structures, cladding and floor panels, it is required:

- determine geometric parameters (width, cross-sectional value, span);

- by removing the protective layer of concrete from approximately the third part of the panel span, install the working reinforcement;

- to find out the strength characteristics of concrete using the instrumental method of analysis;

- detect defects, damage and changes in shape (cracking, deflections and sagging, a decrease in the cross-section of the working reinforcement due to the formation of rust, a decrease in the strength properties of concrete due to saturation, the wrong location of the working reinforcement and its loss in diameter).

Based on the results of the inspection of the plates it is necessary to make design calculations of their ultimate load and crack resistance for the perception of the actions of the existing and expected loads.

When carrying out such calculations, additional information is required on the reinforcement of floor slabs of the following type: the presence and location of compressed reinforcement located along the width of the reinforcement bars, and in addition, whether the slab was prestressed.

rules

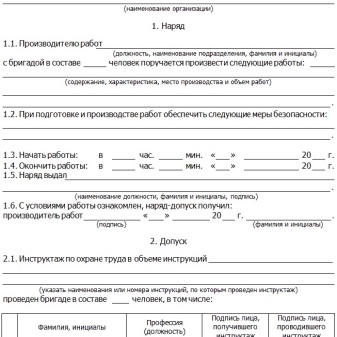

When carrying out work to strengthen floor slabs, in addition to fulfilling uniform safety rules (TB) in construction work in accordance with the chapter of SNiP III-4-80, it is necessary to comply with additional rules that are associated with the peculiarity and conditions of the work performed.

Technological processes (TP), produced on the territory of a functioning production and in working shops, are related to high-risk measures and must be carried out according to a permit. Workers of construction companies must be familiarized with the work plans and undergo an extraordinary safety training due to the high risk of work.

The ways

In the construction of structures and buildings, a variety of types of floor slabs are used: monolithic, ribbed and hollow-core. Depending on the type of panel, the conditions of use and the type of destruction, the specialist in charge of the coordination of construction work decides which type or type of reinforcement to use. The decision is approved in each specific episode, the strength calculation of the reinforcement of the structure is carried out, as well as the technical design is coordinated and approved.

At the moment, there are such methods of strengthening the damaged floor panel: strengthening the floor slabs with iron beams, carbon fiber, as well as strengthening the floor panel from the bottom or from the top by building up a concrete layer and reinforcement. Let's analyze the ways to restore the ability to withstand the load of the floor panel in more detail.

Strengthening timber flooring

As a rule, such structures are restored due to damage or violation of the integrity of the beams. In this case, the wooden floors are reinforced or replaced with beams of a larger section. When a room changes its purpose, or the load on the structure increases, therefore, it is required to strengthen the beams, change them to the largest ones, or increase the number and place them more densely.

For work you will need:

- nails;

- hammer;

- glue to paste over the beams with roofing material;

- anti-putrefactive substance.

The corresponding materials will also be required:

- boards or bars;

- roofing felt for insulating wood.

Beams are strengthened by means of beams or boards of proper thickness, which are nailed on both sides. Boards used for overlays, must be at least 38 millimeters thick, and here is the calculation of the cross-section of the bars and the thickness must be carried out by the designer.

If the aggregate of forces applied to the structure becomes larger, it will be necessary to increase the maximum load of the beams by fixing the linings to their entire length. If it is necessary to repair damaged beams, the pads are applied only in the right places. Basically, they are reinforced at the ends. The reason for the defect of the beams in this place is caused by their incorrect support against the wall. The appearance of condensate moisture favors the fact that the tree decays and loses its strength in the area of contact with the wall.

In order to eliminate such a problem, the ends of the beams must be treated with an anti-rotting agent and covered with roofing material.

Reinforcement of hollow core slabs

A variety of construction methods are practiced to reinforce a hollow-core slab structure:

- creating an auxiliary concrete layer on the surface, reinforced with steel reinforcement;

- strengthening of hollow panels from the bottom side of reinforced concrete massif by means of concreting and steel reinforcement;

- local reinforcement of defective areas and filling cavities with concrete solution;

- strengthening of reinforced concrete slabs with concrete and reinforcement in areas of contact with the wall surface.

For intermediate supports, this can be done by installing single vertical structures in pre-prepared holes in the support areas of adjacent slabs and further concreting channels with auxiliary reinforcement. In this version, the slabs function as continuous beams.

Two ways to strengthen monolithic floors

Strengthening of a monolithic reinforced concrete structure is made by several methods. First of all, the work will require tools and suitable materials:

- puncher;

- jackhammer;

- concrete floor;

- electric welding machine;

- I-beams, channels, corners;

- hairpins;

- boards for formwork;

- concrete (PVA paste, gravel, sand, cement).

Before cutting a small opening in monolithic slabs, the first step is to install the support pillars. Then it is necessary to cut the opening and cut the butt with a jackhammer so that the reinforcement protrudes 15-20 centimeters. After that, a channel is fixed to it along the contour of the opening by welding, a formwork is made from below, and the gap between the channel and the concrete is filled with a prepared concrete solution. Over time, after the concrete has completely adhered, the temporary posts and formwork must be removed.

When cutting out a large opening in monolithic panels and provided that the bearing walls of the lower level (6-12 meters) are close to each other, it is recommended to use the lower suspended retaining reinforcement fixed on the walls. This reinforcement of the reinforced concrete floor is required to be done even before the opening is cut.

Angles or channels of a suitable size are mounted from the bottom end-to-end near the reinforced concrete floor, extremely close to the area of the proposed opening and with two ends are inserted into the recesses made in advance (if the walls are brick). After this, the niches, the gap between the floor slabs and the reinforcement from metal structures are stamped.

In the second version, I-beams and channels on reinforced concrete walls are fastened by means of lock systems created for these purposes. If, when cutting out the opening of the panel, it is not possible to bind to the bearing walls below, and in addition the opening is quite large, in addition to the lower reinforcement in the corners of the opening, pillars are installed between the floor located below and the one in which the opening is cut. These pillars partly take on the impaired ability to withstand the load of the panel.

Cutting monolithic slabs must be done carefully, since factory products have a width of 60 centimeters to two meters. And if you cut a piece of such a panel across its entire width, the other half will certainly fall down. In order to prevent the fall of monolithic slabs, it is necessary to temporarily strengthen the reinforced concrete floor before cutting the opening.

When the opening is small and it is possible to work from two edges of reinforced concrete structures, it is not so difficult to carry out reinforcement. The cut-off part of the panel is fixed to the adjacent ones, in which the opening will not be cut, using the channel supplied from the bottom and tied through with pins through the strip laid on top. As a result, it turns out that The 2 untouched adjoining slabs act as load-bearing beams on which the partially cut floor slab is held.

Reinforcement of U-shaped floor slabs

Work to enhance the load-bearing capacity of U-shaped floor panels can be carried out either by building up a new array of reinforced concrete, or by strengthening the structure with a channel. In this case, the bending stresses on the slab are redistributed to the bearing walls and beams from the channel. Due to the unattractive appearance of the reinforcement, this method is practiced for repair work and the reconstruction of industrial workshops and warehouses.

A similar result is obtained when reinforcing monolithic floor slabs from above with iron beams. This technology secures the damaged slab with a special "bandage" made of 2-T beams or welded channels, preventing it from collapsing.

Reinforcement of ribbed slabs

The method of reinforcing ribbed structures is in many ways similar to reinforcing monolithic panels. From which we can conclude that in this variant it is also necessary to build up the section of the concrete slab in the horizontal plane (concrete slab). Since the reinforcement method is similar to that with monolithic slabs, the tools and materials are the same.

Another method of strengthening ribbed structures in use today is in the execution of auxiliary edges, the location of which is parallel to the existing ones.

To implement this operation, concrete is dismantled in the fixation zones of the new beams, then part of the upper plane is removed in the blocks located in the field of view, which makes it possible to open their middle. After this action, free space appears, which is cleared. After that, reinforcement is put in it, and concrete is poured.It is easy to calculate that due to the creation of auxiliary ribs, the load on any separately taken rib and on the structure as a whole is reduced, which was the main task of carrying out this action.

Application of carbon fiber (carbon fiber)

Reinforcing ceilings with carbon fiber is a relatively new method for the Russian Federation, which was first used in 1998. in gluing the surface with a high-strength material, which takes up some of the stresses, increasing the maximum load of the component. Adhesives are structural adhesives based on a mineral binder or epoxy resins.

Reinforcement of floor panels with carbon fiber makes it possible to increase the maximum load of the structure without reducing the usable volume of the object. The own weight of the building will also not be increased, since the thickness of the components used ranges from 1 to 5 millimeters.

Carbon fiber is a material, not an end product. It creates materials in the form of meshes, carbon strips and plates. The slabs are reinforced by gluing carbon fiber in areas where they are particularly stressed. Most often this is the middle of the span in the lower area of the structure. This makes it possible to increase the maximum bending load.

Tapes and plates are sometimes used in pairs because the mounting methods are identical. But if you want to use nets, then this will eliminate the use of tapes and plates, since you will need to perform "wet" work.

Overlappings are strengthened according to a technique that involves the layout of the panel at the initial stage. It is necessary to outline the places where the amplification components will be located. These areas are cleaned of facing materials, water-cement mixture and dirt.

The compatibility of the work of the plate with the reinforcement components depends on the degree to which the base will be prepared with high quality. Therefore, at the stage of preparation, you should make sure that the plane is even, its reliability and the integrity of the materials in the base, as well as the absence of dirt and dust. The surface must be dry and the temperature must be within acceptable limits. The carbon fiber is being prepared. It is sold sealed in cellophane.

It is necessary not to allow the components to come into contact with dust, which is quite a lot after grinding the concrete. Otherwise the components cannot be impregnated with structural adhesives.

The working area must be covered with polyethylene, along which it is handy to unwind carbon fiber to the required length. For cutting, you can use a clerical knife, an angle grinder or iron scissors.

Helpful hints

There are only two, but very important tips. When carrying out restoration procedures and erection of structures, it is necessary to follow the requirements of technology and practice high-quality raw materials. The calculation of the ability to withstand the load of floor slabs, the possibility of strengthening it must be entrusted to qualified, experienced organizations in this matter. The implementation of these recommendations will make it possible to exclude problem situations in the process of using the building.

For a detailed story about the features of floor slabs, see the video below.

The comment was sent successfully.