Laying floor slabs: technical requirements

During the construction of any structure, floors are used to ensure the strength of the structure, to give rigidity to multi-level buildings. Builders generally use three main methods of installing them. Installation must be carried out by experienced professionals with the necessary knowledge in the field of construction.

Peculiarities

As already mentioned above, the most reliable are three options for the construction of floors:

- installation of monolithic reinforced concrete slabs;

- installation of conventional plates;

- laying wood beams.

It should be noted that all floors differ in shape, structure and technical characteristics. The shape of concrete slabs is flat or ribbed. The former, in turn, are subdivided into monolithic and hollow.

In the construction of residential buildings, hollow concrete ceilings are more often used, since they are cheaper, lighter and are characterized by a higher rate of sound insulation than monolithic ones. In addition, the inner holes are used for routing various communication networks.

During construction, it is extremely important, already at the design stage, to determine the choice of the type of floors, taking into account all technical factors.

Each manufacturer produces plates of a certain nomenclature, their quantity is limited. Therefore, changing the material during the installation process is extremely imprudent and costly.

When using the slabs, certain rules must be observed on the construction site.

- It is better to store the purchased floors on a site specially designated for these purposes. Its surface should be flat. The first slab should be laid on wooden supports - bars with a thickness of 5 to 10 cm so that it does not come into contact with the ground. Between the subsequent products, there are enough blocks with a height of 2.5 cm. They are placed only along the edges; this does not need to be done in the middle. The stack should not exceed 2.5 meters for safety reasons.

- If it is planned to use long and heavy beams during construction, then you should take care of auxiliary construction equipment in advance.

- All work is necessarily carried out in accordance with the project, which must be drawn up taking into account the requirements of SNiP.

- Installation is allowed only by adult workers who have permission and the relevant documents confirming their qualifications.

- When installing floors of multi-level structures, climatic conditions should be taken into account. SNiP norms regulate wind speed and visibility limitation.

Preparation

Any construction has its own project, which is based on several regulatory documents. The main sections of the project.

- Budget plandescribing all costs and terms.

- Routing with an indication of all the processes at the facility, a description of the complexity of each stage and the requirements for the resources used. It should provide instructions for performing specific tasks, indicating effective methods of work, as well as compliance with safety measures. The map is the main normative act of any project.

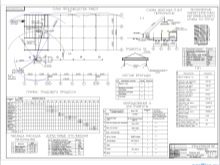

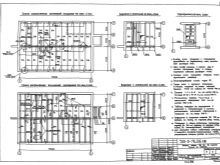

- Executive scheme. Its sample is regulated by GOST. It contains information about the actual execution of design work. It includes all changes made to the project during construction, as well as agreements with contractors for installation.The diagram reflects how correctly the structure was erected, whether it meets the accepted standards (GESN, GOST, SNiP), whether safety measures were followed, etc.

Before laying the floors, leveling should be carried out, that is, make sure that the bearing horizontal plane is ideal. To do this, use a level or hydrolevel. Professionals sometimes use the laser level option.

The difference according to SNiP is no more than 5-10 mm. To perform the leveling, it is enough to lay a long block on the opposite walls, on which the measuring device is installed. This sets the horizontal accuracy. Similarly, you should measure the height in the corners. The values obtained are written directly on the walls with chalk or a marker. After identifying the most extreme points above and below, leveling is carried out using cement.

Before the installation of the slabs, formwork is performed. You can do it yourself or use the factory version. The ready-made purchased formwork has detailed instructions that describe the entire installation process, up to height adjustment.

When erecting wooden floors, formwork is not needed, there are enough available supports.

If the walls are erected from gas silicate materials or foam concrete, then they must be additionally strengthened before installing the ceilings. For this purpose, a reinforced belt or formwork is used. If the structure is brick, then the last row before the overlap must be made with a butt.

In preparation for construction and installation work components for the mortar should be prepared in advance - cement with sand and water. You will also need expanded clay or crushed stone, which fill the holes before roughing.

In hollow ceilings, according to SNiP, it is imperative to seal the holes on the side of the outer wall. This is done to exclude its freezing. It is also prescribed to close openings from the inside, starting from the third floor and below, thereby ensuring the strength of the structure. Recently, manufacturers have been producing products with already filled voids.

If lifting equipment is required for construction, then at the preparatory stage it is necessary to provide for a special site for it. The soil must be compacted to avoid shedding. Sometimes builders put road slabs under the crane.

Before starting the installation, the floors must be cleaned of dirt, especially if traces of old concrete remain on them. If this is not done, the quality of the installation will suffer.

At the preparatory stage, the waterproofing of the foundation is checked for breaks and defects.

Mounting

It will take three people to install the plates: the first is engaged in hanging the part from the crane, the other two install it in place. Sometimes, in large construction, a fourth person is used to correct the work of the crane operator from the side.

Installation work of floor slabs is carried out according to the technology regulated by SNiP norms, as well as in accordance with the drawing and layout agreed in the project.

The thickness of the partition is calculated depending on the projected load. If reinforced concrete slabs are used, then they must be at least 10 centimeters wide, for ribbed options - from 29 cm.

The concrete mix is prepared immediately before installation. It is better to order it from specialized firms so that it has brand strength. The consumption rate of the solution is determined at the rate of 2-6 buckets for laying one plate.

Installation is started from the wall, where a sand-cement mixture with a thickness of 2 cm is laid on a brick or block support. Its consistency should be such that, after installing the floor, it is not squeezed out completely.

In order to correctly and accurately lay the slab, it does not need to be immediately disconnected from the crane slings. To begin with, with tensioned suspensions, the overlap is leveled, after which it is completely lowered.Next, the builders check the height difference using a level. If it was not possible to achieve a certain evenness, then you will have to raise the slab again and adjust the height of the concrete solution.

Experts warn that It is better to install hollow core slabs on two short sides. In addition, you should not overlap several spans with one overlap, as it may burst in an unexpected place. If, nevertheless, one plate for 2 spans is provided in the scheme, then several runs with a grinder should be made in the places of the jumpers. That is, an incision is made on the upper surface above the central partition. This ensures the direction of the crack in the event of a future split.

Precast monolithic or hollow ceilings have a standard length. Sometimes other dimensions are needed for construction, so they are divided by a saw with a diamond disc. It is important to remember that it is impossible to cut round-hollow and flat slabs lengthwise, which is due to the location of the reinforcement in the support zones. But the monoliths can be divided in any direction. Cutting through a monolithic concrete block may require the use of metal rebar cutters and a sledgehammer.

First, you need to make a cut on the upper surface along the marked line. Then the sledgehammer breaks the concrete in the area of the voids and breaks the lower part of the slab. During work, a special lining is placed under the cut line, then at a certain depth of the hole made, a break will occur under its own weight. If the part is cut lengthwise, then it is better to do it along the hole. Internal reinforcing bars are cut with a gas tool or safety welding.

Professionals advise not to chop the rebar with a grinder until the very end, it is better to leave a few millimeters and break them with a crowbar or a sledgehammer, as otherwise the disc may get stuck and break.

No manufacturer takes responsibility for the chopped board, since this procedure violates its integrity, and therefore, technical characteristics. Therefore, during installation, it is still better to avoid felling and use whole parts.

If the width of the slab is not enough, then it is proposed to make monolithic concrete screeds. Below, under two adjacent slabs, a plywood formwork is installed. U-shaped reinforcement is laid in it, the base of which lies in a recess, and the ends go into the ceilings. The structure is filled with concrete. After it dries, a general screed is made on top.

When the installation of the ceiling is completed, the process of laying the reinforcement begins. Anchoring is provided to fix the slabs and give the entire structure a rigidity.

Anchoring

The anchoring procedure is carried out after the slab has been installed. Anchors fasten the slabs to the walls and to each other. This technology helps to enhance the rigidity and strength of the structure. Fasteners are made of metal alloys, usually galvanized or stainless steel.

The methods of interfloor connections depend on the presence of special hinges.

For slinging high-density elements, fastenings in the shape of the letter "G" are used. They have a bend length of 30 to 40 centimeters. Such parts are installed 3 meters apart. Adjacent slabs are fastened in a transverse way, the extreme ones - in a diagonal way.

The procedure for anchoring is as follows:

- the fasteners are bent on one side under the lug in the plate;

- adjacent anchors are pulled together to the limit, after which they are welded to the mounting loop;

- interpanel seams are closed with mortar.

With hollow products, slinging is carried out in the same way, but in addition, a reinforced concrete row is laid out along the perimeter. It is called annular. The fastener is a frame with reinforcement poured with concrete. It additionally secures the ceilings to the walls.

Anchoring can be done by two workers.

Safety engineering

When performing installation and preparatory work, certain safety rules must be observed to prevent accidents. They are spelled out in all construction regulations.

All preparatory and organizational measures in the field of construction are spelled out in SNiP. Among the main ones are the following.

- All employees must have the necessary permits and other documents allowing them to carry out such activities. Engineering and technical personnel are required to instruct, familiarize with safety precautions. Crane operators and welders are obliged to have special training, confirmed by certificates.

- The construction site must be fenced off to avoid misunderstandings and injury.

- The project must obtain all permits and approvals from government regulatory bodies and other auditing organizations. These include, in particular, surveyors, firefighters, technical supervision, cadastral services, etc.

- The erection of the upper levels of a multi-storey building is possible only after the complete installation of the lower ones; the structures must be completed and rigidly fixed.

- If it is not possible to give signals to the crane operator visually (for example, during the construction of large objects), you should install a light and sound alarm system, communication by radio or telephone.

- The floors are cleaned before they are lifted to the site.

- Installation is required according to the established layout scheme.

- In the absence of mounting loops, the part does not participate in lifting. They are either rejected or used for other work that does not require their transportation.

- Prefabricated parts must be stored separately.

- When building multi-storey structures, the rules for working at height are mandatory.

- It is strictly forbidden to stand on the stove at the time of its transportation.

- Providing employees with personal protective equipment is the employer's responsibility. You cannot be on the site without a helmet.

- Removing products from slings is only possible after firmly fixing them on the working surface.

These are just basic rules. The SNiP provides much more conditions for the safe performance of construction work when laying floors.

It is worth focusing on the fact that the construction of structures refers to an activity with a high degree of danger. Therefore, only strict observance of safety rules is the key to saving the lives of workers during the construction of a building and its owners in the future.

Possible problems

When assembling the structure, unforeseen situations of various levels of complexity are possible.

For example, one of the concrete slabs might crack. It should be remembered that when building multi-apartment buildings, you need to lay a certain margin in the estimate. In addition, it is necessary to follow the rules for storing and unloading products in order to avoid such troubles.

If the overlap has burst, then in addition to replacing it, professionals offer several solutions.

- The deformed slab must be supported by 3 load-bearing walls. It should also be put on one of the capital supports by at least 1 decimeter.

- The burst material can be used in places where an additional brick partition is planned from below. She will perform the function of a safety net.

- Such slabs are best used in places with the least stress, such as attic floors.

- You can strengthen the structure with a reinforced concrete screed.

- Cracks in hollow slabs are poured with concrete. Experts advise not to use them in places where a heavy load is planned.

In case of severe deformation, it makes sense to cut the floor and use it where short parts are needed.

In wooden beams, possible defects are various chips, rotting wood, the appearance of mold, mildew or insects.In each individual case, you should carefully inspect the part for its use as an overlap. In any case, many problems can be avoided by proper storage of the material, its preventive processing and careful inspection upon purchase.

For metal beams, deflection is the most significant problem. In this case, you need to do additional calculations, focusing on SNiP. If it is not possible to align the floor to the required level, then the beam will have to be replaced.

How to lay floor slabs, see below.

The comment was sent successfully.