Formwork props: an overview of the types and features of use

In order to obtain an even and seamless monolithic slab, a solid formwork must be installed. For this, support structures are assembled.

Views

Telescopic jack stand

One of the fundamental criteria for choosing a structure is the floor height. Based on this, one of two options is used.

- Telescopic steel posts. They are considered the most economical option and are recommended for use with floor heights up to 4.5 m.

- Volumetric supports. They are used for the construction of monolithic floors with a height limit of 20 m.

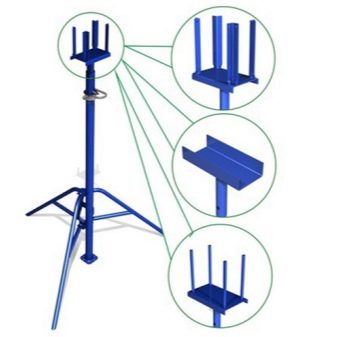

The telescopic stand is more compact in comparison with the volumetric version, so less of them are required for the installation of the formwork. It consists of three elements: a tripod, a jack stand and a support fork.

Tripod ("skirt") - a device that includes three curved tubes and a clamping device. It is used for fixing and does not allow the stand to change its initial vertical position. It takes some of the load on itself. There are various tripod options:

- Reinforced folding W - used to secure racks up to 85 mm in diameter in any hard-to-reach places (corner, wall);

- conventional and lightweight folding L - these options are convenient for fixing racks in limited conditions and belong to the "economy" class.

The jack stand consists of the elements described below.

- Guide support. This is a hollow tube with a diameter of 54-76 mm. On the one hand, a 12x12 mm platform is welded, on the other, a nozzle (tensioner) with applied threads and drilled longitudinal slots for additional adjustment of the rack height.

- Upper support. It is a hollow tube with a diameter of up to 51 mm. The entire length is perforated with a pitch of 120-175 mm. A 12x12 mm platform is welded to the upper part with drilled holes for attaching the unvil.

- Fixing bracket ("earring"). It holds the upper support in a predetermined position due to perforation.

- Support nut. Located on the tensioner. Its presence allows you to more accurately adjust the height of the rack. Provides additional support for the upper pipe.

Support fork (unilk). This is a metal platform from 5 mm thick with a welded pin, due to which the unilk is inserted into the upper pipe of the rack. Designed for fixing horizontal beams.

There are the following varieties:

- with welded or bolted square pins ("horns");

- with a groove for a timber;

- corner on which the timber is fixed with fasteners.

The types of telescopic legs are shown below.

- HUNDRED. The tensioner has a knurled (not cut) thread from the outside (open). The height varies from 1.2 to 4.9 m. The withstand load is from 1.2 to 5 tons.

- STO TOP. They are reinforced struts with open knurled threads. Height - from 1.7 to 5.5 mm. Withstand load - from 3.6 to 4.7 tons.

- STZ. A special sleeve is located on the tensioner, which closes the thread, protecting it from dirt and other mechanical influences. Height - from 1.7 to 4.5 m. Withstand load - from 1.8 to 2.5 tons.

Racks of types STO and STZ are used for overlapping with a layer of up to 300 mm and are installed at a distance of 1.5 m. The guide support has a diameter of up to 60 mm, and a wall thickness of 2 mm. Reinforced struts are used in the manufacture of slabs up to 400 mm thick. The guide support has a diameter of 76 mm and walls with a thickness of 2.8-3 mm. The recommended distance is 1 m.

For the installation of formwork, the following are used:

- telescopic racks;

- tripods;

- univilki;

- beams;

- laminated plywood, corrugated board, OSB sheets or polystyrene panels;

- corners to create edges;

- laser level.

Stages of the assembly of the structure:

- if necessary, the base is prepared: rammed and laid with wooden boards under the tripod tubes (at least two);

- markings are applied along which the tripod is installed;

- the rack is fixed, and the unilk rises to the height specified by the calculations;

- bearing beams are located on the supports, and on them - transverse with a distance of 400-500 mm from each other;

- support corners are installed;

- the formwork is laid without gaps;

- the horizontal position of the support is checked and adjusted.

Now you can proceed to laying the reinforcement mesh and pouring the floor with concrete.

It is important that the base on which the telescopic support for slab formwork is installed is strong and level, otherwise the tripods will not hold the supports vertically, and the concrete pavement will push the supports with its weight and will be uneven.

Among other quality indicators of telescopic racks is the gap between the outer and retractable pipes. The greater the distance between them, the higher the probability of the support fracture under the load of the monolith. To protect against corrosion, the posts are coated with nitro enamels, powder paints or hot-dip galvanized.

The latter last almost 1.5 times longer. True, their cost is much higher.

Volumetric support system

Such a support structure is called volumetric for the reason that they take up all the space. The significant height limit is explained by the fact that such systems are a constructor, which, due to its integrity, distributes the load to all elements at the same time. Unlike racks-jacks, their production does not require verified stages and strict adherence to the dimensions, therefore, they are cheaper for the buyer. Prefabricated elements are covered with a protective paint layer.

There are 2 types of volumetric racks.

- Frame supports (wedge scaffolding or tower-round). They are used when assembling frames (rounds) of finished sizes (without variations), the elements of which are connected to each other using special wedge assemblies and a welding machine. For assembly, slanting reinforcements are required that hold the entire structure as a whole, provide its rigidity and connect the walls from the tour to each other. Additional fasteners are not required for assembly.

As a result, the frame supports can be used as scaffolding for finishing works.

- Modular supports (cup scaffolding). The constituent parts are vertical and horizontal elements of different sizes (the length of the racks is 1-3 m). In contrast to the frame version, the height limit of the modular system increases to 40 m due to the unique connection of the elements to each other. The stress on them only strengthens the connection. It is possible to additionally strengthen the structure using special flanges when installed 1 m apart.

The structure includes the following components:

- two jacks (the lower one is needed to debug the base level, the upper one is to adjust the height of the unilk location);

- starting stand - used only for the first tier of the structure;

- crossbar;

- additional rack - used for all tiers, except for the first;

- unvilka.

The distance between the posts is 1-3 m, the pitch is 0.5 m.

Distinctive features of modular systems are as follows:

- it is possible to move individual units without disassembling, using lifting devices;

- fasteners are affordable, because these include bolts, pins, clamps and other universal means;

- it is possible to order the constituent elements according to individual sizes;

- assembly of the structure is simplified as much as possible and takes less time than other support systems.

Installation of high-rise structures and subsequent work must take place in accordance with the safety requirements:

- workers must have special clothing and helmets;

- the use of personal protective equipment is mandatory;

- employees must be familiarized with the main technical documentation under the signature in the journal intended for verification;

- each employee must have a work permit.

The assembly process includes the following steps:

- using jacks, a horizontally flat platform or base is installed;

- the structure is built up from component elements to the required height;

- univilki are fixed;

- longitudinal and transverse (with a step of 400-500 mm) beams are installed;

- the formwork is being laid.

Dismantling of all supporting structures is carried out in the reverse order, without excluding any actions. The main thing is to be careful, because safety must be first of all.

To reuse the formwork, it must be cleaned, sorted and marked.

Equipment availability

For those who are engaged in monolithic construction on an ongoing basis, it is much easier to acquire new structures - the costs for them will justify themselves. Many developers and manufacturers themselves allow you to use rental or rental services.

Some factories, if they do buy equipment, offer to buy it back after use.

An overview of the telescopic formwork rack in the video below.

The comment was sent successfully.