Formwork lubricant: varieties and tips for selection

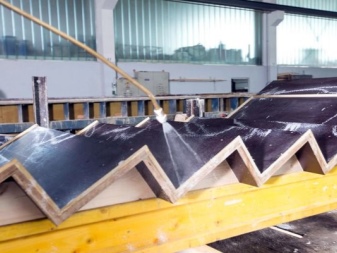

Formwork is a form for curing concrete. It is needed so that the solution does not spread and harden in the required position, forming a foundation or a wall. Today it is made from various materials and almost any configuration.

Features and purpose

The most popular among developers are boards made of boards and plywood, since they can be made from scrap materials without spending a lot of money.

The disadvantage of wooden shields is a large number of gaps and irregularities, which increases adhesion (adhesion of materials) when the mixture solidifies.

For the subsequent dismantling of the formwork, it is necessary to lubricate the formwork panels with special compounds that reduce their adhesion to concrete, which eliminates the appearance of chips and cracks in the structure. Plus, they extend the life of the shields.

This composition is called a lubricant. By composition, they are classified into the following types:

- suspension;

- hydrophobic;

- setting retarding;

- combined.

Lubrication requirements

The lubrication must be suitable the following requirements.

- Should be comfortable to use. Combined formulations have lower consumption.

- Contain anti-corrosion agents (inhibitors).

- Do not leave greasy marks on the product, which in the future may result in peeling of the finish and deterioration in appearance.

- At a temperature of 30 ° C, it must be kept on a vertical and inclined surface for at least 24 hours.

- The composition must comply with fire safety requirements, excluding the content of volatile materials.

- Absence in the composition of substances that threaten the life and health of people.

Types of lubricants

As noted above, the composition of the grease is classified into the following types.

- Suspension. The most inexpensive and economical option (water-based), since this lubricant can be made by hand by mixing semi-aqueous gypsum, lime dough, sulfite-alcohol stillage and water. This type works on the principle of evaporation of water from a suspension, after which a film remains on the concrete. It is worth noting that such a composition cannot be used categorically when vibrating the solution, since the concrete will rip it off the walls. The result is a weakened structure with a dirty surface.

- Water repellent. They consist of mineral oils and surfactants (surfactants) and create a moisture-repelling film. The compositions are firmly adhered to both horizontal and inclined surfaces, without spreading. They are used when working with materials with high adhesion rates, in which they are inferior to other compositions. They are the most popular among developers, although they have some drawbacks: they leave greasy marks on the product, material consumption is high, and such a lubricant is more expensive.

- Set retardants. Organic carbohydrates are added to them, which reduce the setting time of the solution. When using such lubricants, chips appear, so they are rarely used.

- Combined. The most effective lubricants, which are inverse emulsion containing water repellents and set retarders. They include all the advantages of the above compositions, while eliminating their disadvantages due to the introduction of plasticizing additives.

Manufacturers

The most popular products can be identified.

Angrol

Density 800-950 kg / m3, temperature from -15 to + 70 ° C, consumption 15-20 m2 / l. Water based emulsion containing organic substances, emulsifiers and sodium sulfate. It is even used in the construction of bridges. The advantages include the absence of unpleasant odors and the compliance of the composition with fire safety standards.

It can be in the warehouse for a long time due to the introduction of inhibitors, which do not allow rusting of metal forms.

Emulsol

The density is about 870-950 kg / m3, the temperature range is from -15 to + 65оС. It is the most common lubricant with a water-repellent composition. It is a formwork release agent. Consists, as noted above, of mineral oils and surfactants. Alcohol, polyethylene glycol and other additives are also added to it. It can be divided into the following subspecies:

- EKS - the cheapest option, it is used only with non-reinforced formwork;

- EKS-2 is used for metal products;

- EKS-A is suitable for lubricating formwork from any materials, includes anti-corrosion additives, does not leave greasy marks and is economically consumed;

- EKS-IM - winter grease (temperature range up to -35 ° C), improved version.

Tiralux (Tira-Lux-1721)

Density is 880 kg / m3, temperature range is from -18 to + 70оС. Grease manufactured in Germany. It is made on the basis of mineral oils and antifreeze additives.

Almost three times more expensive than domestic products, which is justified by high technical indicators.

Agate

Density is within 875-890 kg / m3, operating temperature is from -25 to +80 ° C. Concentrated emulsion. The composition, based on oil, without water content, allows you to work with absolutely any formwork materials, while leaving no traces and greasy stains. This significant advantage allows the use of such a lubricant even for white coatings.

Table 1. Popular formwork lubricants

Options | Emulsol | Angrol | Tiralux | Agate |

Density, kg / m3 | 875-950 | 810-950 | 880 | 875 |

Temperature condition, С | from -15 to +65 | from -15 to +70 | from -18 to +70 | from -25 to +80 |

Consumption, m2 / l | 15-20 | 15-20 | 10-20 | 10-15 |

Volume, l | 195-200 | 215 | 225 | 200 |

How to choose?

Based on the above, it is possible to summarize the field of application of this or that formwork lubricant.

Table 2. Application area

Lubrication type | Components, composition | Application area | Advantages and disadvantages |

Suspension | Mixtures of gypsum or alabaster, slaked lime, sulphite lye or a mixture of clay and other oils; from scrap materials: kerosene + liquid soap | Application to formwork from any material only when laying, without the use of a vibration device | "+": Low cost and ease of manufacture; "-": mixes with concrete solution, as a result of which the appearance and structure of the product deteriorates |

Water repellents (EKS, EKS-2, EKS-ZhBI, EKS-M and others) | Made on the basis of mineral oils and surfactants | They are used when working with materials with high adhesion rates; this composition is also used in the production of concrete products in the winter | "+": Work with materials with an increased adhesion rate, reliably adheres to vertical and horizontal surfaces; "-": leaves a greasy residue, increased consumption and cost |

Retarding setting | Organic carbohydrates in the base + molasses and tannin | Used for concrete work, both horizontal and vertical structures | "+": In the place where the concrete is in contact with the formwork, it remains plastic, which makes it easy to disconnect from the shields; "-": it is impossible to control the hardening process, as a result of which chips and cracks appear in the concrete |

Combined | Emulsions containing water repellent and set retarders + plasticizing additives | The main goal is to ensure smoothness of the surface and its subsequent easy peeling from the formwork (separation) | "+": All the advantages of the above lubricants; "-": expensive |

Subtleties of use

There are a number of factors on which consumption rates depend.

- Ambient temperature. The lower the temperature, the greater the demand for materials and vice versa.

- Density. It should be borne in mind that a dense mixture is distributed more difficult, which increases the cost of the material.

- The choice of the means of distribution. Roller spraying more than automatic sprayer.

Table 3. Average lubricant consumption

Formwork material | Vertical surface treatment | Horizontal surface treatment | ||

Method | spray | brush | spray | brush |

Steel, plastic | 300 | 375 | 375 | 415 |

Wood | 310 | 375 | 325 | 385 |

To determine the adhesion force, there is the following formula:

C = kzh * N * P, where:

- C is the adhesion force;

- kzh - coefficient of stiffness of the formwork material, which varies from 0.15 to 0.55;

- P is the surface area of contact with concrete.

The mixture can be prepared at home using the concentrate and following the steps below.

- Prepare concentrate and warm water with dissolved soda ash (concentrate to water ratio 1: 2).

- Take a plastic container and pour first "Emulsol", then part of the water. Mix thoroughly and add some more water.

- The resulting mixture should be similar in consistency to liquid sour cream. Then it must be poured into a spray bottle.

- Lubricate the formwork surface.

There are rules that will allow you to use the lubricant correctly and safely:

- it should be applied immediately after the installation of the formwork, which will reduce consumption;

- it is better to use a spray gun rather than hand tools as described above;

- the laid concrete must be covered, protecting it from oils entering it;

- the sprayer must be kept from the boards at a distance of 1 meter;

- you need to work in protective clothing;

- the last, no less important rule implies compliance with the manufacturer's recommendations for use.

An overview of the Gloria spray gun, which is convenient to use for applying lubricant to formwork.

The comment was sent successfully.