PC plates: features, loads and dimensions

Floor slabs (PC) are inexpensive, convenient and irreplaceable building material in certain cases. Through them, you can complete the construction of a car garage, fence off the basement from the main building of the structure, add floors or use it as an element of a single roof structure. Like any similar building material made of reinforced concrete, practiced in various areas of construction and installation of underground gas pipelines, PCs have several varieties of their own. They differ in a number of characteristics that have their own parameters.

Types of plates and areas of application

Floor slabs vary in purpose. They are attic, basement, interfloor. In addition, they differ in design parameters:

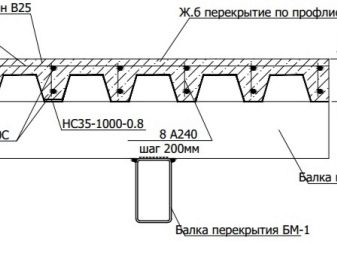

- prefabricated: a) girder from steel beams; b) beams made of wood; c) panel;

- often ribbed;

- monolithic and reinforced concrete;

- prefabricated monolithic;

- tent type;

- arched, brick, vaulted.

Vaults are usually practiced in the construction of stone houses in the old way.

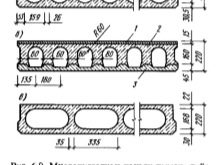

Hollow core slabs

Hollow (hollow-core) PCs have found application in the construction of ceilings at the joints between floors, in the construction of objects made of concrete, wall blocks and bricks. Plates are in demand in the construction of high-rise buildings and individual houses, in prefabricated monolithic buildings and in prefabricated buildings. Hollow reinforced concrete products are often used as load-bearing structures. When constructing industrial complexes, hollow-core reinforced samples of heavy concrete slabs are in demand.

To make them more reliable, they are reinforced with reinforcement or a specialized frame. These panels perform not only load-bearing functions, but also the role of sound insulation. Hollow slabs have voids inside, which also provide additional sound and heat insulation, in addition, electrical wiring can be laid through the voids. Such panels belong to the 3rd group of crack resistance. They are able to withstand heavy loads - from 400 to 1200 kgf / m2). Their fire resistance is usually one hour.

PKZh panels

PKZH are panels that are mainly used in the construction of the first floors. Their abbreviation is deciphered as a large-panel reinforced concrete slab. They are made of heavy concrete. It is necessary to use PKZH only after all calculations - if you install them just like that, then they can simply break through.

It is unprofitable to use them for high-rise monolithic structures.

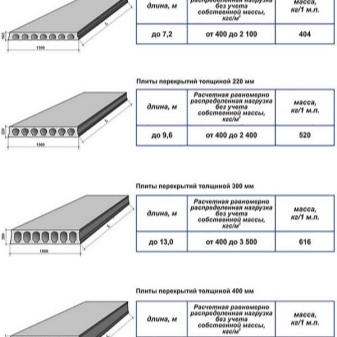

Characteristics of hollow (hollow-core) slabs

The size

The final price depends on the dimensions of the hollow PC. In addition to such characteristics as length and width, weight is of fundamental importance.

PC dimensions vary within the following limits:

- the length of the plate can be from 1180 to 9700 millimeters;

- in width - from 990 to 3500 millimeters.

The most popular and widespread are hollow-core PCs, which are 6 meters long and 1.5 meters wide. The thickness (height) of the PC is also essential (it would be more correct to call this parameter "height", but builders usually call it "thickness").

So, the height that hollow-core PCs can have is consistently 220 millimeters in size. Of course, the weight of the PC is of no small importance.Floor slabs made of concrete must be lifted by a crane, the lifting capacity of which must be at least 4-5 tons.

Weight

Plates produced in the Russian Federation have a weight ranging from 960 to 4820 kilograms. Mass is considered to be the main aspect by which the method by which the slabs will be assembled is determined.

The weight of slabs with similar markings may vary, but only slightly: since if we evaluate the mass with an accuracy of a gram, then this is very difficult to do, since many factors (humidity, composition, temperature, etc.) can affect the mass. If, for example, a slab has been exposed to rain, then it will naturally become a little heavier than a panel that was not in the rain.

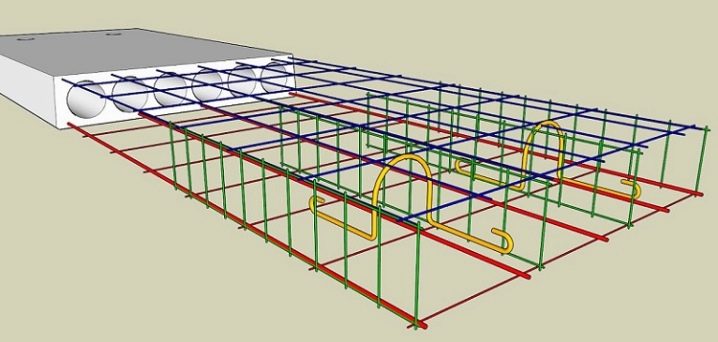

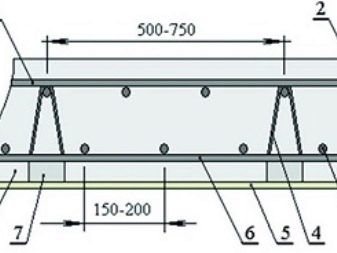

Specificity of reinforcement of PC panels

Production of PC boards is cost-effective, and progressive technological processes provide the possibility of manufacturing structures in different standard sizes. The use of iron reinforcement in the course of production significantly improves the quality properties of reinforced concrete products - it gives the products additional reliability and resistance to all kinds of external influences, and also prolongs the period of its use. Panels of the PK brand are produced according to the 1.141-1 series. At the same time, up to a length of 4.2 meters, ordinary meshes are used for their reinforcement.

Based on the length of the finished panel, two types of reinforcement are used:

- mesh for structures up to 4.2 meters;

- prestressed reinforcement for slabs larger than 4.5 meters.

The mesh reinforcement method involves the use of several types of mesh - the upper one is made of steel wire with a cross section of approximately 3-4 millimeters, the lower one is reinforced with a wire cross section within 8-12 millimeters and additional vertical mesh pieces designed to strengthen and strengthen the end sections of the slab.

The responsibility of the vertical meshes is to create a directional length of stiffness necessary to reinforce the extreme edges on which the above walls and structures exert pressure. The advantages of this order of reinforcement are usually considered to be an improvement in resistance characteristics under deflection load and decent resistance to increased lateral loads.

In the conventional reinforcement method, two meshes are practiced. In this case, the upper one is made on the basis of the wire of the VR-1 brand, and the lower mesh is reinforced. For this, fittings of class A3 (AIII) are usually used.

The use of prestressed reinforcement involves a combination of a conventional top mesh with individual rods with a diameter of 10-14 millimeters, which are located in the body of the panel to some extent in a stretched state. In accordance with the standards, the class of reinforcing rods must be at least AT-V. After the concrete gains its final strength, the rods are released - in this form, they guarantee a decent stability of the structure to seismic and mechanical stress, and increase the maximum load.

For additional counteraction to the emerging lateral overloads, mesh frames are similarly used, reinforcing the ends of the slab and its center.

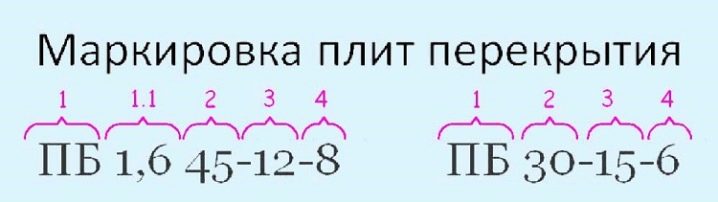

Marking and decoding of plates

In accordance with GOST, all types of plates have their own standards. Their observance is required for installation calculations and when creating projects of objects. Any slab has a marking - a specialized coded inscription that displays not only the overall parameters of the slab, but also its basic structural and strength properties. Being guided by the values of one brand of panels, you can freely decipher others, and regardless of whether the dimensions of the slab are standard or made according to an individual request.

The first letters in the specification indicate the type of product (PC, PKZH). Then a list of widths and lengths (in decimetres rounded to the nearest whole number) follows through a dash.Further, again through the dash - the maximum permissible weight load on the slab, in centners per square meter. meter, not taking into account its own weight (only the weight of partitions, cement screed, interior cladding, furnishings, equipment, people). At the end, a letter addition is allowed, meaning additional reinforcement and the type of concrete (l - light, i - cellular, t - heavy).

Let's analyze an example and decipher the marking. Panel specification PK-60-15-8 AtVt means:

- PC - plate with round voids;

- 60 - length 6 meters (60 decimeters);

- 15 - width 1.5 meters (15 decimeters);

- 8 - the mechanical load on the slab is allowed up to 800 kilograms per sq. meter;

- AtV - the presence of additional reinforcement (class AtV)

- t - made of heavy concrete.

The thickness of the slab is not indicated, since it is the standard value of this structure (220 millimeters).

In addition, the letters in the markings provide the following information:

- PC - standard slab with round voids, or PKZh - large-panel reinforced concrete slab;

- HB - single-row reinforcement;

- NKV - 2-row reinforcement;

- 4НВК - 4-row reinforcement.

Hollow core slabs are widely practiced in construction due to their high performance characteristics. The perfection of hollow core slabs has been verified by both construction specialists and individual developers. The main thing is to correctly choose a slab designed to create an overlap in a high-rise building or an individual building. The recommendations of professional builders will save you from potential mistakes.

In the next video, you are waiting for the laying of PC floor slabs.

The comment was sent successfully.