Monolithic overlap: device and types

Monolithic flooring is one of the most popular options for arranging horizontal elements. It is used in buildings and structures used in low-rise construction, in the event that the layout of the facility differs from the standard one. For example, when there are no internal load-bearing walls and partitions, or the spans exceed the dimensions of standard ready-made slabs produced by an industrial method. There are various ways of arranging monolithic floors - using beams or beams, on corrugated board or removable formwork.

What?

How to determine which monolith is best for a private house? When choosing the optimal design, it is worth paying attention not only to the features of the material used and the layout of the walls of the building. It is also necessary to take into account the loads that the plate has to withstand. This will allow you to accurately determine the number and characteristics of the reinforcement, providing it with strength.

A monolithic floor is a type of supporting structures that have a horizontal position in space, created by pouring metal reinforcement with concrete. Its arrangement provides opportunities for the formation of a solid foundation that can serve as a support for the further operation of the building. When self-concreting a monolith, formwork with reinforcing rods inside is used. The use of solid ceilings will be absolutely justified in the following cases.

- When erecting buildings with complex configuration parameters or original architecture. When it is impossible to make the entire structure of the prefab, you have to supplement it with monolithic sections. But it would be much more rational in this case to immediately complete the arrangement of a single slab over the entire building.

- In case of difficulties with the delivery and transportation of plates, the impossibility of using heavy crane equipment.

- In the presence of non-standard spans, which cannot be covered with serial reinforced concrete products. In this case, solid ribs for reinforcement or beam supports for intermediate posts can also be used.

- Under severe operating conditions of the facility. The higher the floor load, the more likely it becomes to replace standard composite slabs with a monolith. With high humidity and noise level, only solutions should be used that have sufficient resistance to adverse environmental conditions.

- When erecting monolithic and prefabricated monolithic structures, in which the well-proven technology of formwork installation and knitting of reinforcement is used.

With the right approach, the choice of a monolithic floor is guaranteed to give a lot of advantages in the further operation of the building.

Advantages and disadvantages

How much cheaper is a monolith than slabs? It all depends on the area on which the work is to be carried out, the complexity of the process. But such a decision also has obvious drawbacks that should be taken into account before the final decision is made. In particular, a monolithic concrete floor requires a gradual build-up of strength. Accordingly, labor costs and completion times of the process will be significantly higher than when using conventional stoves. But these inconveniences are completely covered by the advantages that this solution has:

- high bearing capacity - withstands even the shock of a blast wave and significant vibration loads;

- no restrictions on the size of spans, in some cases, supports in the form of columns are used;

- the locality of the installation process - everything is created on site, directly at the facility;

- the ability to independently carry out work, without involving the labor of third-party specialists;

- the longest possible service life - due to the varying thickness of the concrete, it is possible to prevent exposure of the reinforcement for many decades to come;

- high level of fire safety, the ceiling is made of non-combustible material and does not support combustion processes;

- no operational difficulties - no need for maintenance, replacement of load-bearing elements;

- reducing the thickness of the structure without losing its strength.

Another important point: the need to maintain a certain temperature and humidity conditions during concreting. This method will not work if the construction requires meeting a tight deadline, because the maturation of the mixture takes time. In addition, in living spaces, the ceiling created with the help of a concrete monolith needs additional finishing. And its arrangement requires a certain strength from the foundation and walls. For example, the bearing capacity of wooden beams or logs will not be enough.

Device

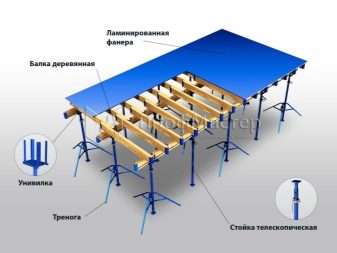

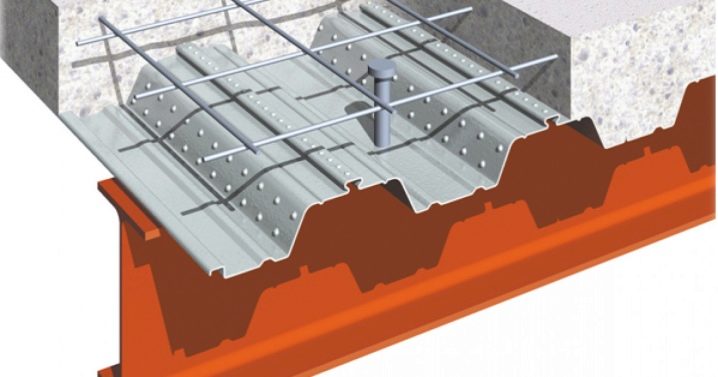

All types of reinforced concrete floors are divided into monolithic, often ribbed and prefabricated. If we consider a solid slab as a base, then for its pouring it will be necessary to use formwork, which allows to ensure the correct formation of a concrete layer with reinforcing components inside. This can only be achieved by using an external removable or non-removable frame. Most often, the device of reinforced concrete beam and bezelless slabs on corrugated board is used, which is relevant for industrial and commercial buildings.

In residential buildings, removable inventory formwork is used, which makes it possible to dismantle the frame after the concrete has gained the specified strength and hardness.

Thickness

Among the parameters that are important in the construction of a monolithic floor, first of all, the thickness is distinguished. According to the calculated standards, this figure should be 1/30. That is, the average values will correspond to 30 mm per 1 m span. The longer the distance from wall to wall, the thicker the monolith layer should be. If the operational loads of the future structure are not too high, it can be made thinner by 10-15%.

Stress-strain state and reinforcement

When calculating the reinforcement of monolithic foundations, the SSS indicator is always taken into account, taking into account the further "behavior" of the material, its resistance to deformation loads. Depending on the installation method, the slabs do not bend in the same way. That is why, when determining the optimal nature of the installation of reinforcement, it is necessary to calculate in advance the method of fixing it and the distribution of loads. The nature of the support is determined by highlighting the nodes / points on which the maximum load falls.

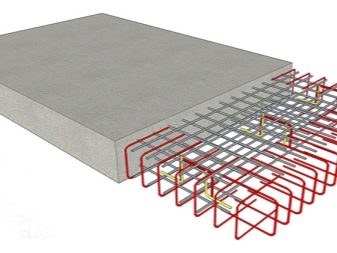

The properties of concrete allow it to exhibit high compressive strength. But the material is not resistant to tensile loads. Reinforcement is intended to solve this problem. The finished composite material (reinforced concrete) requires the use of rods corresponding to their characteristics.

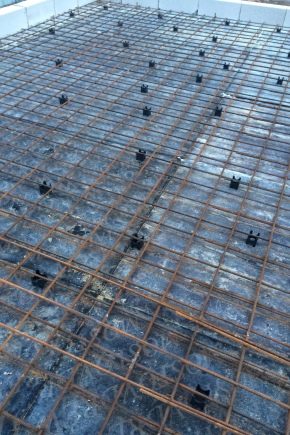

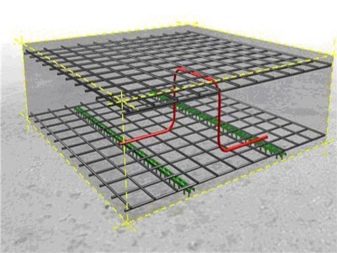

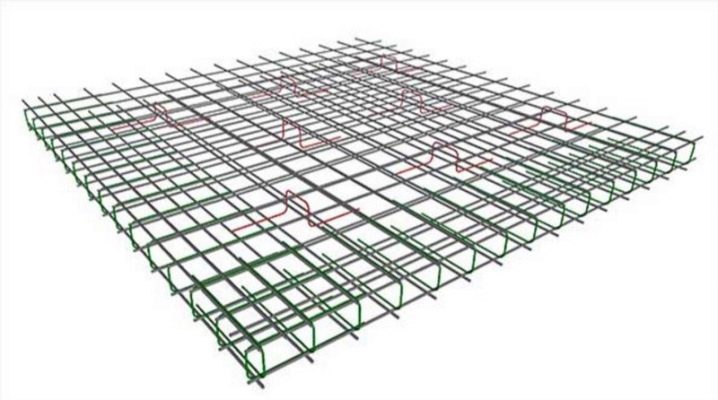

Installation of reinforcement is carried out in areas subject to the greatest tension. It is called longitudinal or working and requires the use of rods with a periodic profile, designated as A400. The choice of pitch (distance between individual elements) is important. The standard range is 150-200 mm, with the center and edge of the board being the most important areas. In the presence of supporting elements (columns, intermediate walls), these zones are also subjected to the greatest stress.

Reinforcement at the top and bottom of the concrete layer requires the formation of vertical joints by transverse reinforcement. In difficult operating conditions, with significant loads, the presence of this component prevents delamination of the concrete monolith. In the absence of such influencing factors, the role of transverse reinforcement is rather constructive; here, rods with a smooth profile are used.

Views

A monolithic floor in a house or non-residential facility can have a girder or a non-girder structure. In the case of the presence of supports, beams and girders used in the construction of the slab become one with it. Beamless solutions are created without protruding ribs, but they have sections extending 0.3 m from the edge of the span. In girder versions, there are cross-shaped or transverse cross-beam supports.

The simplest formwork for erection is the non-girder version of floor slabs. It can be used to set a complex architectural shape and volume to monolithic capitals. The support columns are arranged in a square-mesh method, with an even distribution of loads. With their help, it is easy to get a smooth reinforced concrete ceiling.

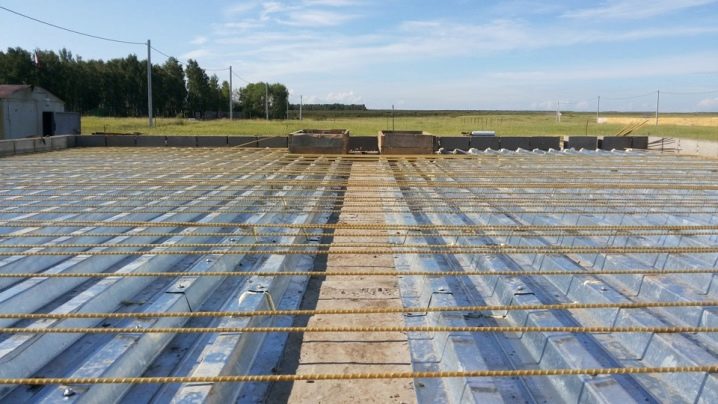

Installation of reinforced concrete on corrugated board is regulated by SNiP II-23-81 and is carried out in cases where it is necessary to erect buildings and structures with a wide range of available loads. When forming a monolith on a profiled sheet, it is necessary to ensure its protection with a galvanized coating or polymer spraying so that corrosion does not damage the material in the future.

When creating monolithic structures, aggregates from expanded clay concrete, foam concrete and other crushed fractions can be used, which increase the noise insulation characteristics. The sectional drawing helps determine the thickness of the infill layer and the distribution of all components within the slab. The expansion joint in a monolithic slab is created with a support type of installation in order to avoid cracking of the material. In open areas, shrink and insulating strips are placed at a distance of about 3 m.

How to choose?

When choosing a monolithic floor that will be equipped in a house, it is better to take into account all factors. For a building with several floors, it is better to use removable inventory formwork, which can be easily and quickly assembled on site. In the private sector, you can use girderless structures. But if the load is significant, the forces of the columns and supports may not be enough.

An interfloor space filled with a reinforcing cage may require additional insulation for insulation and noise reduction. In this case, the space between the floors is filled with concrete with the addition of expanded clay. The column version is more suitable for non-residential properties, commercial, retail buildings or open plan spaces. On walls made of foam blocks, it is better to use not a monolithic concrete slab, but lighter floors. If a solid version is chosen, the load calculations should be as accurate as possible.

Payment

To perform the calculation of a monolithic floor, it is recommended to use special programs that allow you to quickly solve the problem. The SNiP manual, which sets out the main technical parameters, is taken as the basis for calculating the frame and the support unit. The scheme will include the following parameters:

- reinforced concrete mass - standard is equal to 2500 kg / m3;

- the weight of the floor structure built on top of it, partitions - 150 kg / m2 (average values);

- payload - it will be at least 300 kg / m2.

The selection of reinforcement is performed by the program along the X and Y axes, taking into account the expected and simulated deformation loads. The length of the project, the class of concrete and reinforcement, and the thickness of the cover are also taken into account. When calculating, the own weight of the floor is summed up with a similar indicator, but taking into account the reliability of the load, the weight of the partitions, and the calculation of the temporary load.By adding these parameters, you can get information that is applicable when developing sketch solutions.

Another component of the calculations is the determination of the moment forces in the sections of a monolithic slab. It is calculated based on the design parameters and is determined individually. Determination of the number of reinforcement is carried out according to the average weight coefficient - it is equal to 80 kg / m3. The area of the slab is multiplied by its thickness and multiplied by a value of 80. The result is equal to the total mass of the reinforcing bars.

For information on what a monolithic overlap is, see the next video.

The comment was sent successfully.