Comparison of foam and foam

Polyfoam and polystyrene foam are the most popular insulation materials for cladding houses. From the material in this article, you will learn how they differ from each other, what is better to take for solving specific problems.

Appearance and description

Both insulating materials are sheet-shaped. These building materials are produced from the same primary raw materials. However, few people know that penoplex is a type of foam. It is produced using a special technology that changes the properties of the finished insulation.

Externally, both types of panels appear to be the same. On closer inspection, you can see the difference in structure and tactile sensations. The color also differs: the polystyrene plates are white, in contrast to the foam insulation.

Materials have different geometry precision. In this regard, the extrusive heat insulator wins. It is easier to join it when carrying out thermal insulation works; due to the special processing of the edge, it does not create voids between the plates.

Foam sheets differ in surface in the form of obvious balls filled with air inside. These slabs are slightly rough to the touch.

Analogs of the second type have a greater surface smoothness and density. They have fused polystyrene beads.

The thickness of the blocks can be from 2 to 10 cm. Individual slabs are made according to the customer's specifications. The weight of the foam heat insulator is 15 kg / m3, of the foam one - from 28 to 35 kg / m3.

Difference in production technology

Polyfoam is produced by foaming polystyrene. The technology does not involve pressure. The granules are processed with steam and increase in size by more than 10-40 times. Then they are glued together.

In view of this, there are voids between the balls. The volume of polymer used in the board does not exceed 2%. The remaining 98% are airborne. The material is gas-filled and has excellent thermal insulation qualities.

Penoplex is produced from polystyrene by the extrusion method. The pellets are exposed to high temperature and pressure. They are subjected to uniform pressing, which increases the density of the boards.

Due to this, the weight is also different: it is larger for expanded polystyrene sheets. Penoplex has a more uniform structure, it has smaller closed pores. During production, molten foam is extruded from the extruder under pressure.

Outwardly, it looks like polyurethane foam with practically indistinguishable cells. The production technology affects the cost of the finished material.

Which is warmer?

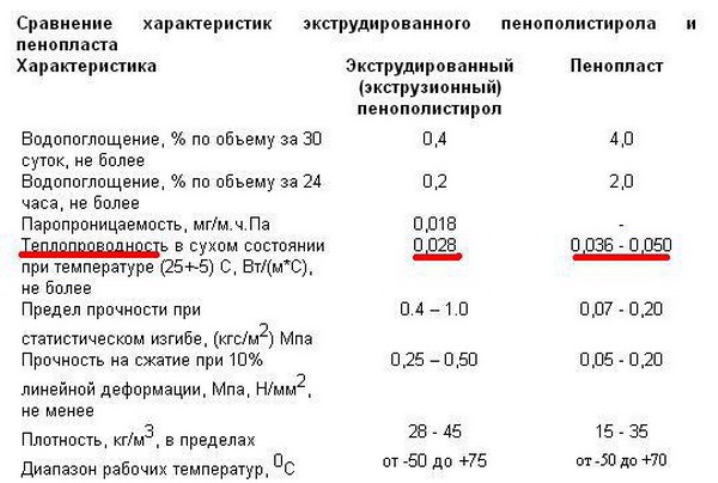

Penoplex has the best heat-saving properties. It retains heat better because it has no voids between tiny fused granules. If we compare the thermal conductivity of both types of insulation, then foam boards are 25% more efficient.

The maximum possible heat-conducting properties of the foam are 0.04 W / m. For a foam heat insulator, the value is 0.029-0.03 W / m. The working temperature range for the first is from -40 to +70 degrees, for the second - from -50 to +75 degrees.

For equally high-quality insulation, less compressed foam is used. It not only performs its functions better, but can also have a smaller sheet thickness. Its density is much higher.

Comparison of other characteristics

The differences between the two types of heat insulators lie in other technical characteristics.

Strength

Strength characteristics are related to production technology. Due to its structure, the foam is noticeably inferior to the analog product. It crumbles and breaks even with a slight mechanical stress at the joints of the granules with glue.

Melted and glued pellets, reduced in size during production, have better adhesion. The tensile and compressive strength of penoplex is about 6 times higher.

On the practical side, when insulating the floor, PPP does not require protection with dense sheets. Foam blocks are suitable for wall and ceiling cladding. In this case, the thickness of the block often does not matter.

The foam has no flexibility, it is quite fragile and can break with intensive deepening of fasteners. With penoplex, this will not work. It is more difficult to break, it is elastic and is not afraid of bending.

Foam blocks can only be laid on a flat surface. Ignoring this condition leads to cracking of the building material. Both are susceptible to rodent damage.

The difference between them lies in the ability to withstand loads. In this regard, the foam is significantly inferior to the improved analogue. It has a fairly dense and strong structure, thanks to which it is resistant to deformation.

It can be used for floors, eg under screeds. It will not change its characteristics under the weight of people and installed furniture. At the same time, the density of the heat insulator varies.

Flammability

Building materials have different flammability properties. Heaters support smoldering, because of which the fire goes to other combustible objects, a fire flares up. Polyfoam refers to products with a category of normal flammability (G3).

Penoplex is highly flammable (G4), it is more harmful than its foam counterpart. To eliminate this problem during production, it is treated with special substances - fire retardants.

But this treatment does not make it less hazardous in the event of a fire. In this case, poisonous gases will be released into the air.

Formally, self-extinguishing varieties are considered the best, but they smoke a lot when smoldering. Polyfoam has to be protected from fire by plastering.

Moisture permeability and vapor permeability

The level of water absorption of heat insulators varies. For a conventional insulation, it is 2%, for an extrusive analogue - 0.35%. The difference in density determines the characteristics of the water absorption of materials.

Penoplex blocks have practically no air and moisture permeability. The water absorption of the foam is higher. Expanded polystyrene analog is practically inert to water, it endures 50 cycles of defrosting and freezing.

The vapor permeability coefficient of foam blocks is slightly higher. Therefore, the walls inside the premises are often trimmed with a polystyrene heat insulator. There are no pores and air pockets in the structure of the penoplex, it does not allow steam to pass through.

Terms of service

Manufacturers of both types of thermal insulation claim an unlimited service life. Estimated estimated time is 50 years. However, this value can be significantly reduced due to the effect of ultraviolet radiation on the surface of the blocks.

Besides, an important factor is accuracy during delivery and insulation. The foam crumbles at the edges, it squeezes when the dowels are driven into it. Broken edges reduce the quality of the seams; in this regard, penoplex is more durable.

Under conditions of identical mechanical stress, the foam breaks into separate pieces. Cracks may form on it. Its average service life is conditional, due to its deterioration, technical characteristics are reduced.

Price

Material price depends on different technical characteristics and material properties. For example, the key ones are density, thickness, the presence of anti-flammable impregnations, resistance to stress, and the brand of the manufacturer.

Regular foam is cheaper than foam. Premium Penoplex is much more expensive because it is more effective.1 m3 of this heat insulator exceeds the price of foam blocks by 1.5 times.

Polyfoam is cheaper, the price of a sheet with parameters 100x100x5 cm and a minimum density ranges from 51-85 to 200 rubles. The average cost of extrusive thermal insulation is 1,500 rubles for a package of 7 blocks measuring 118x58x5 cm and 1,780 rubles for 4 slabs 10 cm thick.

Penoplex packages with a small thickness (2-3 cm) cost up to 2,000 rubles. In this case, the number of blocks may vary.

What is the best choice?

The choice of a specific heat insulator for house insulation depends on the tasks set.

- Both types of building materials can have different thicknesses. This criterion is selected taking into account the climatic characteristics of the region.

- Expanded polystyrene is considered a more practical material for insulation. Builders consider it a versatile raw material for thermal insulation of external and internal surfaces.

- Important indicators are the conditions of insulation, the type of surface. When choosing a specific type of heat insulator, the brand and series for the planned work are taken into account.

- In addition, the most convenient block sizes are selected, reducing the number of insulation scraps. They are determined with the optimal density, which directly affects the strength and quality of insulation. The brand of the manufacturer is important.

- Pay attention to the packaging of the unit. Its integrity is considered to be a guarantee of purchasing whole slabs with a perfect edge required for better joining of the slabs.

- Due to the smaller thickness of the foam blocks, useful space is saved, which is especially important for small-sized premises. The scope of application of penoplex depends on the density.

- Sheets with a density of 28-33 kg / m3 are suitable for thermal insulation of roofs (pitched and flat, with and without load). Analogues with indicators of 25-30 kg / m3 are suitable for cladding internal partitions, wall ceilings (outside and inside).

- Blocks with a higher density are used for thermal insulation of facades of buildings and foundations, as well as for a screed, for a garage. Plates 35-45 kg / m3 are used to insulate heavily loaded structures (runways, highways, foundations).

- The purchase of foam sheets is justified if a minimum budget is provided for the insulation of the structure. In addition, they are suitable for insulating a facade, loggia, balcony without using a vapor barrier.

- Foam blocks are also bought when it is necessary to ensure the minimum possible weight of the structure.

- In European countries, this insulation is not used for facade decoration due to toxicity. In our country, it is purchased most often in order to save money during construction work.

- In addition, as a noise isolator, it is ineffective. However, it is a prevention of the formation of condensation inside the walls. Penoplex is strong, but does not have this ability.

- As for durability, both materials must be covered with finishing raw materials after covering the floor. The sun's rays destroy both heat insulators equally well.

The comment was sent successfully.