Calculation of the weight of the foam block

Foam concrete is a reliable modern material that has been used in housing construction for quite some time. It is lightweight and durable and can be installed very quickly. But it is important to assess the severity of the structures so as not to buy the wrong blocks.

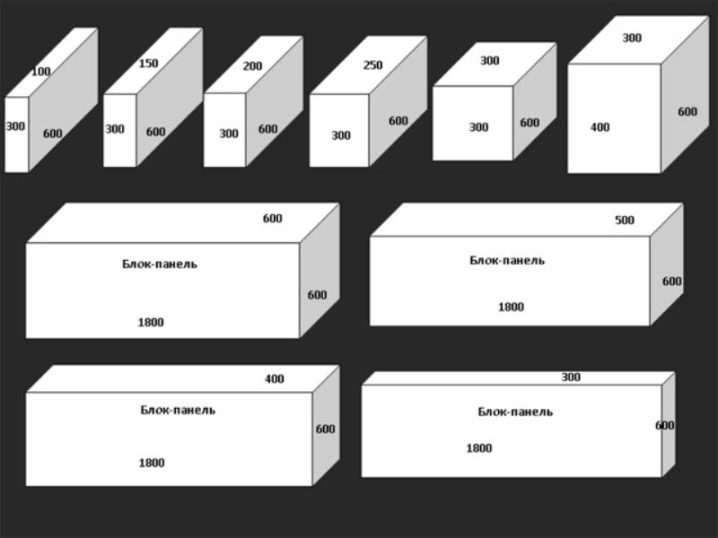

Product dimensions

The most demanded size of foam blocks is 600x300x200. It is he who is used to erect internal load-bearing walls. Building the same load-bearing walls, but outside, is required from structures 600x400x200. The partitions dividing the rooms must be made of blocks of 600x300x100 mm, but only if the slightest load is excluded. Products with dimensions of 600x250x100 allow increasing the height of residential buildings, measured in floors, without additional strengthening of the foundation.

More foam blocks 100x250x600 are needed to:

- renovate old houses;

- lay out interior and load-bearing walls;

- make overlaps between floors;

- create chambers for freezing and heat treatment of products.

Block elements 600x250x75 are also suitable for the formation of interior partitions. Returning to products 100x300x600, it should be noted that they have an optimal balance between strength, weight and heat conservation.

You can also order (indicating the number of pieces) foam concrete of other formats:

- 600x250x200;

- 600x250x50;

- 600x300x250.

What does weight affect?

Weight, or rather, density of foam concrete, directly affects its market value. The lighter the material, the cheaper it sells. In addition, transportation costs directly depend on the severity of the building material. Some blocks can be lifted and assembled by hand, while others cannot be put in place without the use of technology. Naturally, all this is reflected in the timing and cost of work, in the overall labor intensity of construction manipulations.

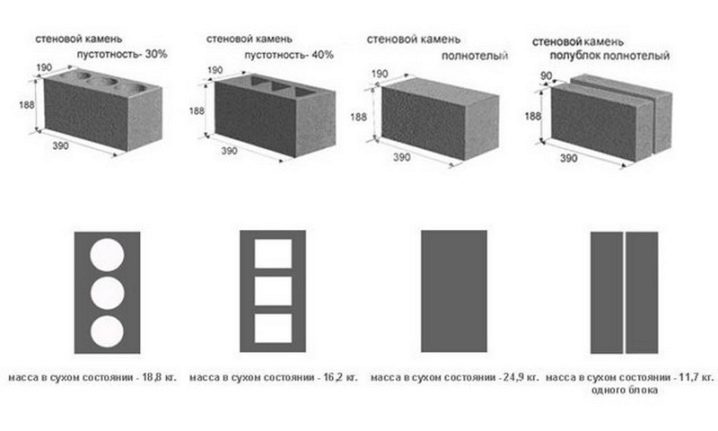

But there is one more extremely important circumstance. Differences in the density of foam concrete determine the area of its use. So, products of groups 300, 400 and 500 are suitable only for thermal insulation. Even the smallest load reflects badly on them. The D600-D900 format combines structural and thermal insulation characteristics.

Such elements will withstand a certain mechanical stress and retain heat well. It is them that are recommended to be used to build a house of 1-2 floors. For central Russia, such blocks are suitable without an auxiliary insulation layer. The foam block D1000-D2100 belongs to the construction group. All such elements are in demand mainly in the construction of apartment buildings, they definitely need enhanced thermal protection.

There is one more circumstance. Some manufacturers violate the standard recipe for the sake of cost reduction. Both fine crushed stone and crushed brick are added to the composition of foam concrete. As a result, the thermal performance of the material deteriorates, and its strength also suffers. But no amount of disguise in appearance will allow the buyer to be misled if he knows exactly what the mass of a building block should be.

A high-quality foam block is a subspecies of aerated concrete. Its structure should be porous, formed by uniformly distributed air fragments. The technological process is organized according to the non-autoclave method.

A flawless product must include:

- sand (river, well washed, or extracted from a quarry);

- foam forming agent;

- cement M400 or higher;

- clean industrial water.

It is necessary that first a dry composition of sand and cement be prepared. Then it is mixed with water in the exact proportion. And only in the last turn are the components that form the foam added.By the standard density, one can judge whether there are a lot of air pores in the material. And also this indicator tells what the relative proportions of sand and cement mass are.

How to calculate?

The standard specific weight of 1 m3 of foam concrete can be determined by the category to which it belongs. So, if the material is classified as D400, the mass is 1 cu. m. will be 436 kg. For the most massive category D600, the spread will be from 450 to 900 kg. Foam concrete of the D1000 group should weigh on average 1100 kg. But all these figures are achieved only with strict adherence to existing standards.

In reality, even when the standards are strictly followed, there is a fairly wide range of values. Special measuring devices help to calculate the weight of one foam concrete block. But not every construction site has them. And therefore it is nevertheless necessary, first of all, to start from the category of density.

This density is determined by how much per 1 cubic meter. m. has:

- sand;

- water;

- cement.

The calculation of the volumetric weight of a foam block cube in kg in the first approximation is carried out simply by density (while moisture is deliberately neglected). The point is simple - multiplying volume by density. But in practice, humidity is much more important than it seems. As water is absorbed, the total mass of the block increases noticeably, sometimes by 1/5. The volume itself is predictably calculated by multiplying the length by the height and the width.

Suppose you need to find out how much a block weighs with a relative density of D600, the dimensions of which are 600x200x300. The total volume of such a structure is 0.036 cubic meters. m. As follows from the marking, 1 m3 of foam concrete has a mass of 0.6 tons. Therefore, the weight of the block will be 21 kg 600 g. But there is another nuance.

For 1 cubic meter m. volume accounts for 27.8 pieces. foam blocks with dimensions of 20x30x60 cm. If you take blocks of 10x30x60 cm, a little more than 55 products will fit in the same volume. Knowing the mass of 1 unit of production, it is possible to calculate what the weight of a pallet or pallet loaded with foam concrete will be. The problem is that all these calculations do not take into account sorption moisture. And here the provisions of GOST 25485-89 come to the rescue. According to them, the level of sorption moisture content of foam concrete can reach 8-15% (when creating a material based on sand).

If ash is used as a filler, the foam material can absorb an additional 12-22% of water. The exact figure is determined by its initial moisture content. Let the sorption moisture correspond to the lowest indicator (8%). In this case, for a product with a size of 600x200x300 mm, it will add an additive by weight in 1728. Conclusion: the total mass of the foam block will be no less than 23.328 kg.

Based on the maximum possible level of sorption moisture, the total weight will reach 26.352 kg. In order not to carry out the calculations yourself, you need to consult the manufacturer. In this case, it is worthwhile to carefully study all the official certificates. After all, the latest production technologies and differences in humidity levels can greatly affect the final result. The mass of the blocks is 600x300x200 mm more than that of a brick.

But due to the reduced density and the reduction in the amount of cement for the masonry, the total pressure on the foundation is reduced. This is equally important for a wall unit and a partition unit. But the area of application significantly affects the weight characteristics of foam blocks. So, D300-D500 thermal insulation structures have a mass of 12-19 kg. And the structural elements of the D600-D900 have the smallest weight 23, the largest 36 kg.

The heaviest construction parts with dimensions 600x300x200 weigh 40-47 kg. The average weight of the partition wall is 21 kg. It should be borne in mind that, according to Russian GOST, it is categorically unacceptable to produce foam blocks longer than 0.6 m. A wall-mounted heat-insulating foam block has a mass of 11.6-19.5 kg. If we consider the option of a partition wall insulation product measuring 10x30x60 cm, its weight turns out to be record low - only from 5.8 to 9.7 kg.

Let's look at another calculation option. Let there be a foam concrete element of category D400 with dimensions of 20x30x60 cm.Its total volume is exactly 0.036 cubic meters. m. Accordingly, the weight of the concrete structure will be 14.4 kg. This, of course, is again "dry mass". By introducing a correction for absorbed water, you can get more objective figures - 15.55 and 16.6 kg.

It is also necessary to introduce a correction for water in relation to the heaviest porous concretes. For categories D1000-D1200, the dry weight is 47 kg. When saturated with liquid from the air, it grows up to 50 kg. It seems to be a little, but if you need to transport dozens of blocks, even for a truck, the difference is no longer indifferent.

IMPORTANT. The so-called reinforced foam blocks, which supposedly correspond to higher strength categories than it follows from the mass, are in fact just a publicity stunt.

For information on how to calculate the weight of the foam block, see the next video.

The comment was sent successfully.