Polycarbonate greenhouse: sizes and varieties of shapes

The greenhouse is an integral part of almost any Russian vegetable garden, the owners of which are focused on getting a good harvest. His presence on the personal plot makes it possible to start the summer cottage earlier and extend it for the maximum possible time.

There are a huge number of greenhouse models on the market today. There are plenty to choose from. In addition, many people prefer to build this structure on their own, taking into account the individual dimensions and characteristics of their land plot.

Features: advantages and disadvantages

When it comes to arranging a greenhouse, many people often confuse it with a greenhouse, thinking that there is no difference between them.

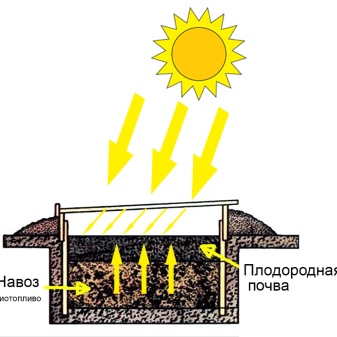

If a greenhouse needs sunlight to provide a microclimate suitable for plants, and in certain cases coal, gas, electric or even wood heating can be used, then the greenhouse is self-sufficient in the energy sense.

It is "heated" by manure or compost, in which the biological decay process takes place. The principle of the greenhouse operation is indicated by its own name, since the design allows you to create a greenhouse effect.

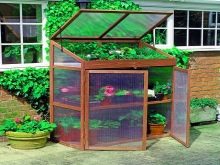

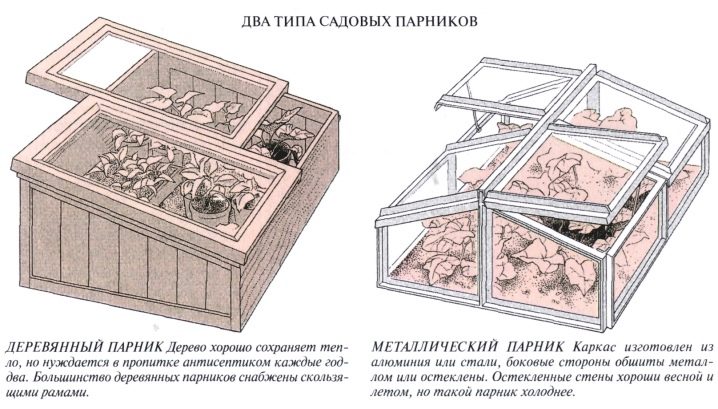

Unlike a greenhouse, there are no doors in a greenhouse that you can enter. Usually this is a small structure that allows you to ventilate the interior space due to the raised cover or removed walls.

The efficiency of the "work" of the greenhouse depends on the choice of material for construction. In the old days, glass was often used to create it. (Although such designs are still found in vegetable gardens in our time). Sometimes ordinary window panes were put into business, which periodically had to be replaced, since they broke quite often.

The same story happened with polyethylene. Despite the fact that cucumbers and seedlings feel great under it, this material may not be enough even for one season. The only annoying nuisance is enough when such a shelter tears with a storm wind or a sharp object.

Better than glass and polyethylene polycarbonate, which is already becoming common in the manufacture of greenhouses and greenhouses. It is two hundred times stronger than glass, and it makes no sense to compare it with polyethylene by this indicator. This product of modern life will cost more than traditional materials that are gradually becoming obsolete in the garden, but it can serve for a long time. It will be convenient to use such a greenhouse.

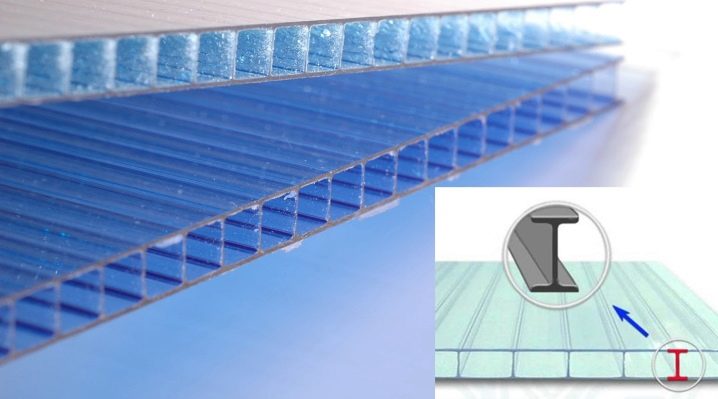

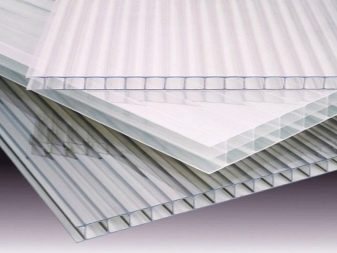

Polycarbonate is a type of plastic. On sale you can find monolithic and cellular polycarbonate. Monolithic is actively used in construction, but for the construction of "houses for plants" it is better not to take it, since it is not intended for active retention of heat. Better to use a cell phone.

In it, between two thin polymer sheets, so-called stiffeners are installed at regular intervals, connecting both halves of the coating to each other. The cavities between the connectors are filled with air. Due to this structure, cellular polycarbonate transmits light well and weighs little, and maintains heat much better than its monolithic counterpart.

Types and forms

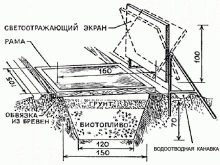

Depending on their design, greenhouses are deepened and aboveground.

Recessed looks like a trench with a top harness of planks, bricks or other materialavailable on the farm.Due to such a device, the "special bed" requires less "heating agent". Recessed greenhouses are made with both a gable and a gable roof, as well as an arched one. At the same time, those with flat sheds are called Russian, and gable houses are called Belgian. And they are suitable for tall plants.

An aboveground greenhouse is otherwise called portable. It also has a Parisian or French name. In such a structure, a "cushion" of manure is located under a layer of soil. As the "coolant" decays, the greenhouse has to be renewed.

Ready-made polycarbonate products for growing various garden crops are usually an aboveground option. Although you can pick up one that can be used as a roof for an in-depth version of the "insulated beds". And if there is nothing suitable for sale, it is not difficult to independently build a greenhouse covered with a polycarbonate honeycomb sheet.

A frame greenhouse is often made on a metal base, this "skeleton" is galvanized, sometimes reinforced.

Modern buildings for vegetables are distinguished by a variety of different configurations and intricate names. Many people get the proud prefix "eco". It can be an ordinary rectangular greenhouse with a roof. There are polycarbonate shell-type open top with hinged lids.

An interesting version of the butterfly greenhouse. Its walls rise up, so you can freely approach the plants from any side. In hot weather, such a structure is easily ventilated.

The tulip greenhouse has a sliding principle of adjustment, as well as a breadbasket, which is very convenient for a summer cottage with a limited area of a vegetable garden, where every square meter of land is worth its weight in gold. The advantages of such structures are obvious in comparison, for example, with an arched and film-covered greenhouse "peppercorn".

A round greenhouse looks original. It can be, for example, an arched structure. Such structures are used both for germinating seedlings, and for full-fledged cultivation of various crops, including the stage of harvesting fruits. The warmth is remarkably well kept under the dome, and the structures themselves of this shape are durable, withstanding a good layer of snow in winter.

In addition, round greenhouses can decorate summer cottages and garden plots.

There are also completely advanced models of structures with automatic ventilation that can save the summer resident from unnecessary winding from the city to his site and back in order to close or open a greenhouse with his favorite cucumbers.

Homemade polycarbonate greenhouses, created by skillful hands, in many respects repeat the forms and principles of action of store brothers and outwardly sometimes do not differ from them.

Dimensions (edit)

The size of the greenhouse is an individual matter. Someone with the help of a mini-type construction is able to provide himself with fresh vegetables for the whole summer, growing them per square meter, and for someone, a 3 by 6 site will not seem enough. Someone is used to a 4 x 8 meter greenhouse and gets a stable harvest from it for years.

A small greenhouse will find its place in a limited area vegetable garden. Narrow, sometimes very low designs are also appropriate here.

The size of the building may also depend on how the plants are located under its roof. It is necessary to understand what the width of the tracks is convenient for processing in a particular case, how many of them are needed in total. This will help to navigate what area and configuration of the greenhouse will suit a particular user.

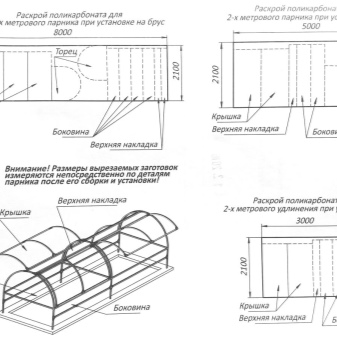

When determining the area of a polycarbonate structure, you must also keep in mind that a standard sheet of material is 2.1 by 6 meters. It is no coincidence that greenhouses 2 m wide can be found quite often. Given that the material is cut, it is easy to build structures of various sizes - from small to very impressive. It can be approximately 6x3, and 2x3, and 2x4, and 3x4, and 2x6 m.

The height of the greenhouse is usually about one and a half meters or less.

Frame materials

To create the frame of the future greenhouse, you can use different materials. This can be, for example, wood, metal profile, plastic or metal-plastic.

The tree is most available for creating the foundation of the structure. Such a frame is easy to assemble. It is durable and stable. It can last a long time if you choose a material of decent quality for construction and process it correctly. In order for a structure based on such a basis to be truly durable, you need to use only dried wood without signs of decay, and after creating a "skeleton", do not neglect the application of moisture-resistant paint to it.

It is very convenient to attach polycarbonate to a wooden frame. And a particularly reliable foundation for such a greenhouse is not required. It is enough to make support pillars.

Metal frames are durable and have a decent service life. They are often made from shaped pipes or thick fittings. Since such a foundation for construction is heavier than a wooden one, in some cases a strip foundation is made under it. Even when pouring it, pipes for the frame are installed in it.

There are difficulties in using metal for a greenhouse. The metal structures themselves cannot be called cheap, and in order to mount the frame, you need a welding machine plus the ability to use it.

A good option for arranging a greenhouse is to use metal-plastic pipes. They do not need to be specially treated to protect them from the effects of natural processes leading to destruction, as is the case with metal and wood. And this justifies the cost of purchasing the pipes themselves.

This material is as durable as metal, while the installation of a frame from it is no more difficult than from wood. Reinforced-plastic pipes bend well. This allows you to make comfortable arched structures out of them.

Just make a frame for a greenhouse made of polypropylene pipes. Using various nodal elements, it is easy to create structures of a wide variety of shapes and sizes.

How to choose?

The choice of a greenhouse is due to the specific tasks that the owner of the land sets for himself. For seedlings, which will then be transplanted to the garden bed, you can arrange a small "house" of the simplest form, for example, resembling a chest with a hinged lid. Although if the seedlings are grown for sale, a significant area will be needed.

In almost every area where they are seriously engaged in gardening, you can see a greenhouse for cucumbers and peppers. The most convenient cucumber greenhouse is considered to be a butterfly-type design and a breadbox. It is convenient to ventilate it, and besides, there is no need to reach for vegetables when picking them.

How to wash?

The polycarbonate coating needs periodic processing, since during the summer season green traces from plants, earth and other dirt accumulate on it. The coating ceases to transmit enough light, which impairs the quality of growth and well-being of the next "green tenants" under its roof. Microorganisms sometimes accumulate on polycarbonate that can destroy future crops.

To avoid damaging this material, do not use abrasive cleaners., with which, for example, wash dishes, and stiff brushes, and even more so with metal nets. For washing in this case, a soft cloth or sponge is useful, as well as ordinary water with soda. You can also use a soapy solution. All detergents used during the treatment must be properly removed with clean water. To be sure, you can spray the structure with a hose.

Manufacturers

There are many people in Russia who are in love with land and agriculture. The demand for products for the garden and garden is always great. Therefore, it is not surprising that there are enough manufacturing firms supplying relevant goods to the market.

According to customer reviews, among the leading manufacturing organizations that create prefabricated greenhouses and greenhouses, the following can be noted:

- "Harvest";

- "The foundation";

- Glass House;

- Novoladozhsky Plant;

- "Will".

They offer a wide range of designs adapted to the difficult Russian climate and capable of satisfying the needs of even the most discerning customer.

How to do it yourself?

To prepare a vegetable garden for spring without depriving it of such an important component as a greenhouse, you can not only purchase a store product, but also build a small structure yourself that can meet all the requirements of the owners.

Experienced summer residents advise planning a construction site either in March or at the end of November. This is equally practical, since the season of active activity on the land is still far away. At this time, there is no risk of damaging any plants in the beds. And the temperature for working with polycarbonate is the most suitable - about +10 degrees.

If the installation is carried out at too high a temperature, then when it gets colder, the polycarbonate will "shrink" in size and the joints between the sheets will turn into gaps, from which valuable heat will then evaporate. If the construction is carried out in cold weather, then with the arrival of summer it will be found that the structure is distorted, since the polycarbonate has expanded. As a result, all your labors will go to waste.

When thinking about building, you need to keep in mind a number of factors:

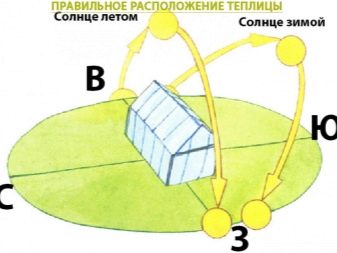

It is important to correctly place the structure on the site. It is better to orient the building from west to east. This will allow the plants to receive more sunlight.

If the greenhouse should be no higher than one and a half meters, construction using arched arcs will be a wrong decision. The highly curved polycarbonate cover reflects light back, so the temperature inside the building will not be much higher than outside. It is easier and more rational in this case to make a "house for plants" with flat walls and a roof.

It is possible to make it stronger not only by special strengthening of the structure, but also by "leaning" the structure against the southern part of another building - a shed or, for example, a residential building. Such a neighborhood will protect the greenhouse from strong winds.

When starting to work with polycarbonate, it should be borne in mind that it bends easily in one direction and badly in the other. This is due to the properties of the honeycomb structure. When installing a greenhouse, this must be taken into account so as not to ruin some of the available material.

You need to start the construction itself from the stage of drawing up drawings.

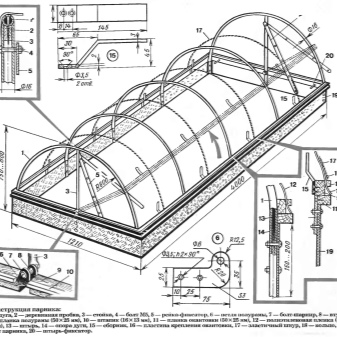

To make a greenhouse on a metal frame, you will need:

- polycarbonate 4-6 mm thick;

- adhesive tape for waterproofing seams;

- metal mounting profiles;

- silicone sealant.

You also need to stock up on a tool:

- screwdriver;

- scissors for metal;

- self-tapping screws;

- garden drill.

The work begins with the installation of the foundation, since the greenhouse will have a mass of several tens of kilograms. The easiest way is to make a base for a building on four pipes dug in at the corners of the building. Pipes need to be painted for waterproofing, and then driven into drilled wells to a depth of about a meter so that future supports protrude twenty centimeters above the earth's surface.

To assemble the frame of the building, the metal profile is cut according to the scheme. Its elements are connected with self-tapping screws and attached to the foundation. Further, in accordance with the dimensions previously indicated in the drawing, pieces of polycarbonate are cut out.

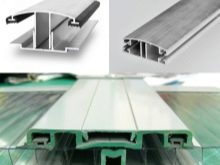

We do the assembly on the frame in one of the ways. Using a strip of metal: cover the junction of the polycarbonate sheets with a piece of aluminum tape. We attach it to the "skeleton" with self-tapping screws so that they fall into the base through the gap between the sheets of the greenhouse cover.

The second method of fastening is using an H-shaped profile, which is just intended for this kind of cases: it is attached to the frame, after which you can easily install polycarbonate sheets into it.After completing the installation of the walls, the joints between the semi-carbonate sheets are treated with silicone sealant.

At the ground, the structure is sheathed with a metal strip or boards that have been treated with an antiseptic. The same is done with the edges of the greenhouse.

The lid of the building can be made from a piece of polycarbonate attached with self-tapping screws to the body of the structure.

If you have at least some building experience, it is not at all difficult to create a greenhouse of an unpretentious design.

For information on how to make a butterfly greenhouse with your own hands, see the next video.

The comment was sent successfully.