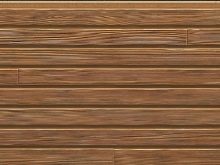

Facade panels for wood: features and benefits

Facing facades with wood always looks stylish and respectable. However, the cost of such finishing is high, and the tree needs constant protection. Due to its high moisture permeability, fire hazard and tendency to decay, the material cannot serve for a long time. An excellent alternative are facade panels made of durable materials that imitate wood texture.

What it is?

Facade panels "imitating wood" are slabs or siding boards, the front side of which imitates one or another type of wood. The basis of such a material can be siding, metal profiles, fiber cement and other materials. As a rule, such panels perform not only decorative functions, but also have high performance properties.

Unlike wood, such materials are non-combustible (for example, fiber cement panels) or more resistant to combustion. Modern materials for the facade are characterized by low moisture absorption, and also have a waterproofing base that prevents the penetration of moisture from the walls into the thickness of the material.

Cladding panels also compare favorably with wood in frost resistance and weather resistance. During the entire period of operation, panels from a bona fide manufacturer retain their color and original appearance. It should be noted that natural wood surfaces darken after the first winter.

Modern wood-like panels are environmentally friendly and biostable. If a tree is susceptible to infection by wood-boring beetles, and dampness becomes covered with mold, then using panels such problems can be avoided. High rates of heat and sound insulation are also an advantage of the panels, and thanks to the installation features, it is possible to lay a layer of insulation between the material and the walls of the building.

As for the appearance, thanks to modern technologies, plastic, metal siding and fiber cement panels "imitating wood" imitate the shades and texture of wood as accurately as possible. Even on closer inspection, it is not always possible to notice that the luxurious wood surface is just an imitation.

The material is characterized by ease of fastening, which is due to the equipment of the panels with a locking mechanism or grooves. Thanks to them, the solidity of the structure is also achieved, the resistance of the facade to wind loads.

As you know, wood shrinks (sometimes up to 15-20%), which leads to warping of the structure. The use of wood-textured panels allows them to be mounted without taking into account deformation during the shrinkage process. After cladding, you do not need to wait 6-12 months before proceeding with further wall decoration.

Finally, unlike natural wood, the panels do not need regular maintenance and treatment with special compounds. Most of them are capable of self-cleaning, others only need to be washed periodically with water. The service life of the panels varies from 20 to 50 years.

Views

Depending on the material from which the panels for the exterior decoration of the house are made, several types are distinguished.

Plastic

Such panels are available in vinyl and acrylic varieties. They are characterized by moisture resistance, weather resistance, frost resistance. The products are strong enough, however, with significant mechanical stress, they can crack. They are considered the lightest panels, therefore they do not require strengthening of the facade.

Metallic

Metal siding panels have a large margin of safety compared to their PVC counterparts. This leads to high indicators of their wear resistance, a long period of operation. The basis of the products is aluminum profiles or "stainless steel". The metal itself is susceptible to corrosion, however, manufacturers carry out high-quality anti-corrosion protection of the material, so that moisture and rust are not afraid of it.

Fiber cement

The material is based on purified cellulose and cement mortar. Sometimes, in order to increase the strength, quartz sand is added to the composition. The result is a durable material that can last up to 100 years.

Low moisture resistance, fire resistance (fiber cement does not burn and does not melt), frost resistance up to 100 cycles, as well as high thermal insulation properties in combination with affordability - all this is the reason for the increasing popularity of fiber cement products. Thanks to the ceramic coating, the panels also exhibit high UV resistance.

The disadvantage of the material is its rather large weight (on average, 15-25 kg / m kW). It is worth noting that plastic analogs weigh only 3-5 kg / m2 kW. This fact requires the use of a solid foundation.

Separately, we can single out multilayer sandwich panels, a distinctive feature of which is a layer of insulation. Due to this, the surfaces to be faced do not require the installation of a layer of heat-insulating material. Sandwich panels allow you to quickly build a neat ventilated facade.

There are wood-polymer "sandwiches" made from waste wood processing enterprises. The shavings and sawdust are given a uniform size (like wood dust), after which the mixture is filled with polymer resins. As a result, a material appears that looks like a chipboard board, but has moisture resistance, strength, and biostability. There are also laminated surfaces that are even more resistant to moisture and more "elegant" appearance.

Veneered panels are rarely used due to their relatively high cost. The material is a paper-cellulose composite base, on the front surface of which a layer of fine wood veneer is applied. From above it is closed with a protective polymer layer.

Depending on the purpose of the material for exterior decoration, facade and basement panels are distinguished. The latter are fixed in the lower, basement part of the building. The base is subject to higher mechanical stress, active action of moisture, dirt, road reagents, freezing. It is logical that the material for finishing this section of the facade should have higher performance characteristics.

Plinth panels fully comply with these requirements. Each line (plastic, metal, fiber cement) has a collection of such products. Despite this, experts recommend refraining from using plastic products in the lower part of the building. Preference should be given to stronger and more durable counterparts made of metal, as well as on the basis of fiber cement.

Design

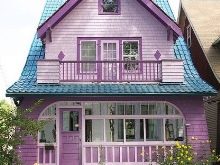

The panels can imitate any wood surface. The most popular are panels for timber, rounded logs, eurolining, ship or other board. Thanks to the use of inexpensive (compared to wood) wall panels, it is possible to turn an unsightly structure into a respectable building, decorated with such rare species of wood as oak, beech, cedar.

The use of woodgrain panels is primarily suitable for buildings in a “rustic” style. It can be both a traditional Russian log house and alpine chalet houses, as well as exquisite buildings in the spirit of Provence.

For the Provence style, bright colored panels that look like painted boards are suitable.For the Scandinavian style, it is preferable to use bleached boards, as well as analogs painted in gray, graphite shades.

Wooden slabs go well with stone or metal surfaces, as well as materials that imitate plaster.

As a rule, the lower part of country houses is laid out of stone (or rather, panels that imitate natural stone), the rest of the facade is made of wood-like panels.

The combination of panels imitating lining and brickwork looks original. To avoid the monotony of wooden surfaces, as well as to add dynamism to the exterior, the different orientation of the "lining" allows.

When using only wood-like panels in decoration, it is recommended to combine 2 contrasting or 2-3 similar shades. So you can add volume to the facade, emphasize the architectural elements.

Installation features

Despite the fact that the installation is quite simple, it must be carried out taking into account certain requirements.

Fastening of products "under a tree" can be done directly on the walls or on a pre-created lathing. The latter can be wooden or metal (the preferred option, since it does not require additional processing). Installation on a crate allows you to hide defects and unevenness of surfaces, to preserve an air gap between the facade and the wall, as well as to make external insulation of the facade, laying a layer of heat-insulating material between the crate and the wall.

First of all, a starting profile is mounted on the crate, which serves as the beginning for laying the remaining plates. It is fixed at a distance of 10 cm from the corners. Plates are stacked from bottom to top. Additional elements and accessories are used to decorate corners, ledges, platbands and other elements of the facade.

When purchasing material, it is important not to forget about the need for a stock (for the likelihood of marriage, cutting). As a rule, another 10-15% is added to the main number of panels for the stock.

A detailed review of CEDRAL fiber cement siding is waiting for you in the video below.

The comment was sent successfully.