All about lumber

Lumber has been used by people in construction since ancient times. Houses and outbuildings were erected from them, furniture was made. Humanity has constantly invented and created new wood products. Every year they improved and went along the path of their development to those materials that are on the market today.

What it is?

Lumber Is a wood product obtained by sawing timber and having at least two parallel planes. Timber procurement, processing and manufacture of various products from it are carried out in the aggregate by the forestry and woodworking industries. The first branch is responsible for the cultivation of forests, that is, reforestation, and the preparation of timber. These tasks are performed by logging enterprises - forestry, forestry and sawmills. They felled trees and cut sawn timber, typical of which are logs and poles.

The next link in the process is woodworking enterprises... Timber prepared for recycling is delivered there. Logs are sawn on sawmills in accordance with national and international standards. This is how lumber is produced, which include boards, beams, bars. The process of their manufacture is lengthy and consists of many links.

This is necessary in order to avoid mistakes and improve the quality of the production process. As a result, we get finished wood products used for construction and finishing works.

Lumber differs from wood composites - laminated veneer lumber, fiberboard and chipboard, plywood, which are produced by the same enterprises... They have a multicomponent composition and are products of tertiary forest processing. Like any other human activity, the manufacture of wood products has both positive and negative effects on the population and the environment. Among the advantages of wood materials are their environmental friendliness, ease of installation, relatively high strength and good bearing capacity. Quality lumber has an attractive appearance and affordable cost, has a pleasant woody aroma.

The main disadvantages of timber processing are the massive felling of trees, and with them the destruction of animals for which the forest is home. Deforestation is exacerbating the problem of global warming. People destroy forests, then grow new ones, but the latter die due to fires and drought. It is impossible to make good lumber from dead wood, so they go into the firebox. This closes the circle.

Regulatory Requirements

Lumber production is a strictly standardized process. Each enterprise has quality controllers who check product batches for compliance with all requirements. Standardization of dimensions and quality is necessary in order to subsequently facilitate the use of wood-based materials in construction. Each link of timber processing has its own standards. For example, lumber production meets the following standards: GOST 8486-86, GOST 6564-84, GOST 24454-80. There are the same national standards that determine the technical conditions for the transportation and storage of sawn timber and billets.Most of them comply with global quality standards - DIN, EN, ANSI, ASME. This allows states to trade lumber on the international market.

Wood is an organic material. It is always a potential carrier of viruses, bacteria, parasites and various insects, which pose a danger not only to other vegetation, but also to the person himself. Therefore, the export and import of forest products requires compliance with sanitary standards. The quarantine control of wood materials is carried out by the State Inspectorate for Seed Production and Plant Protection. The duties of the service include checking the safety and certification of forest products. If, during inspection and analysis, at least one product does not meet sanitary standards, the entire batch is disposed of.

In case of complete safety of products, the party receives a phytosanitary certificate, which allows the manufacturer to transport products across the border. The phyto-certificate is a kind of product quality guarantor.

Other parameters that are indicated in the quality passport:

- name of the supplier, trademark, production address;

- grade;

- sizes;

- wood species;

- the number of units in the batch;

- designation of standards.

Views

There are various classifications of sawn timber, which take into account many parameters: the method of sawing, strength, type of sorting, method of end-face processing, and more. The main thing is the classification of products according to the degree of their processing. According to her, products are divided into several types.

Trim

Such lumber is processed from all sides. They have planed and ground faces - wide parts, as well as machined parallel edges. Obsol - processing defect - should not exceed the specified values. Edged materials have several quality categories: selected, first, second, third and fourth, which are indicated by the corresponding marking. They are made dry, wet and wet with antiseptic impregnation.

They are ordinary and profiled, having tongue-and-groove connections. They are used in the construction of load-bearing and supporting structures of buildings, roofs, as well as for interior decoration of premises.

A separate group of products is made up of glued composites, which are made by combining several materials into one.

Unedged

Such products are processed only from two sides. The edges remain uncut and often contain bark. Unedged materials are mainly used for the construction of auxiliary and temporary structures. They have a rough texture, unattractive appearance and low cost. The variety is usually not identified. Unedged lumber can be used in themed interiors of hunting-style rooms.

They are suitable for finishing garages, outbuildings, sheds. Overlapping due to uneven edges. Unedged products also include obapol or slab. This is humpback lumber obtained from the side of a log. One of its sides is sawn, while the other is convex and contains bark. Currently, such products are considered industrial waste.

Planed

These are products in which both edges or at least one face are planed. Both edged and unedged materials can be planed. Subsequently, they are subjected to grinding on machines to give the planed surface more smoothness.

Calibrated

This is a separate group of sawn timber that is completely dried and processed to the specified dimensions and characteristics. Such products are used in international trade, as well as for the construction of structures where technical errors are unacceptable: shipbuilding, car building, construction of supporting and supporting structures of buildings, roofs.

After manufacturing, lumber is treated with special solutions. Products impregnated with antiseptics, insecticides and fire-resistant liquids have a long service life, retain their original qualities and appearance for many years.

Materials (edit)

The flora of our planet is characterized by a wide variety of tree species with different characteristics. They are divided into coniferous and deciduous.... Let's consider the most commonly used breeds.

Larch

The wood of this species is considered to be the best. She really no equal in terms of strength and durability... Such materials are difficult to process, but they are absolutely not subject to decay. The breed has a high degree of moisture resistance... Has a slightly reddish natural color and does not need additional painting.

Oak

Quite strong and dense wood, which has excellent properties: it does not crack when drying out, is practically not subject to decay. Oak is considered the king of deciduous forests and has an attractive texture.

Beech

Wood is similar in quality to oak, but is highly susceptible to decay... It is white with a yellowish-red tint. The beautiful texture makes it possible to use beech for sheet veneer and parquet friezes.

Birch

It is a typical representative of hardwood. Birch wood has light shades, has average strength and hardness. The disadvantages of the breed are its susceptibility to decay, cracking and severe shrinkage over time.

Aspen

Another type of hardwood. Its wood is soft, white, with a greenish tint. It can be easily processed. Aspen is considered a moisture resistant breed, does not crack or warp over time.

By its properties, the breed resembles a linden tree.

Cedar

Cedar, like fir, is almost similar in structure to pine. They have a beautiful texture that looks attractive on smooth, polished surfaces. The wood is soft, resinous and has a pleasant soothing aroma.

Pine

A typical representative of conifers. The wood has a yellowish tint and is easy to process. The low hardness of pine does not allow it to be used for the construction of supporting structures and building frames. Among the disadvantages are abundant resinousness and a strong coniferous aroma, therefore, pine wood is not recommended for finishing in bedrooms.

Ash

The rock has good parameters of strength and elasticity. It has a light yellow color combined with a dark red core, a beautiful texture. Ash wood is easy to process, not prone to cracking and rapid decay.

Shapes and sizes

At the enterprises, sawn timber is produced in standard sizes in accordance with the standards of GOST. It is allowed to manufacture products of arbitrary sizes at the request of the customer. The sizes are determined according to certain rules.

- Length in m. The smallest distance between opposite ends.

- Width in mm. Edged - anywhere on the workpiece at a minimum distance of 150 mm from the end. Unedged - in the middle part of the workpiece as the sum of the halves of the dimensions of a wide and a narrow plane, excluding bark and bast.

- Thickness in mm. Anywhere on the workpiece at a minimum distance of 150 mm from the end face.

Long metal rulers and calipers are used to measure dimensions. It is allowed to use templates, calibration blanks and other meters, the error of which meets the standards. Control measurements of dimensions, as well as weight, are carried out after the wood has dried.

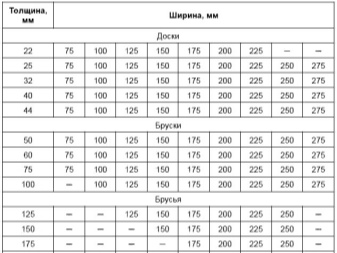

Consider the nominal sizes of certain types of products.

Beams:

- length - 1.5-8.5 ± 0.25-0.5 m;

- thickness –100-240 mm;

- width -100-280 mm.

Bar - produced with dimensions similar to boards, but less flat in shape.

Board:

- length - 1.5-6.5 ± 0.25-0.5 m;

- thickness -13-35 mm thin, 36-100 mm thick;

- width - 50-260 mm.

The listed parameters refer to materials with a moisture content of 20%. With larger or smaller values of the parameter, the dimensions of the wood may differ, respectively, up or down.

In order to avoid manufacturing defects, it is necessary to determine in advance the degree of moisture content of the material, then multiply the dimensions by the corresponding coefficient of shrinkage in accordance with GOST 6782.1.

Sawing methods

The first step in creating lumber is cutting the logging. Its technology determines the appearance and strength of the finished product. Cutting of materials can be longitudinal or transverse. For this, various types of woodworking machines are used: circular with circular saws and band saws with flexible saws.

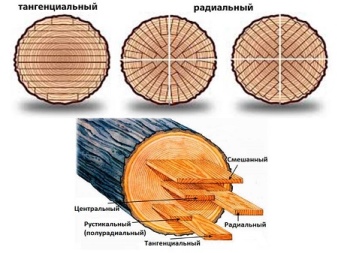

There are several options for circular sawing.

- Radial The cut line in the section fits to the core of the trunk, like the radius of the circle. The result is a product with straight parallel fibers. Such materials have a more attractive appearance due to the homogeneous texture and the minimum distance between the fibers. It is used to create expensive decorative boards. Advantages - a high degree of strength, no material shrinkage.

- Tangential With this method, the cut line passes at some distance from the core of the trunk, which in cross-section looks like a chord of a circle. Such products have an interesting curly texture with wide dark light lines of fibers. The main disadvantage is the low degree of fiber strength and strong shrinkage of wood over time.

- Semi-radial or rustic This is a cutting method that combines the features of the previous two. Uneven gaps of wood fibers are visible on the surface, which gives the product a unique appearance. The method is inferior in quality to radial sawing, but better than tangential.

- Transverse This is the way to cut against wood fibers. It is rarely used, mainly to create artistic parquet or cutting kitchen boards, since in this case the products have poor performance.

- Mixed combines the features of other methods. It is the most cost-effective, it allows you to get a larger number of blanks from one log.

Assortment

Today on the lumber market, you can find a large number of varieties of products.

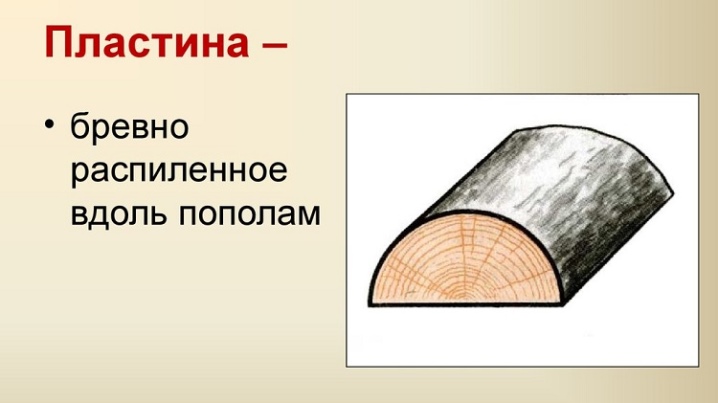

Plate

These are pieces of wood that are made by one longitudinal cut through the center into 2 equal halves. They have only 1 sawn side and are used for the production of the entire range of sawn timber.

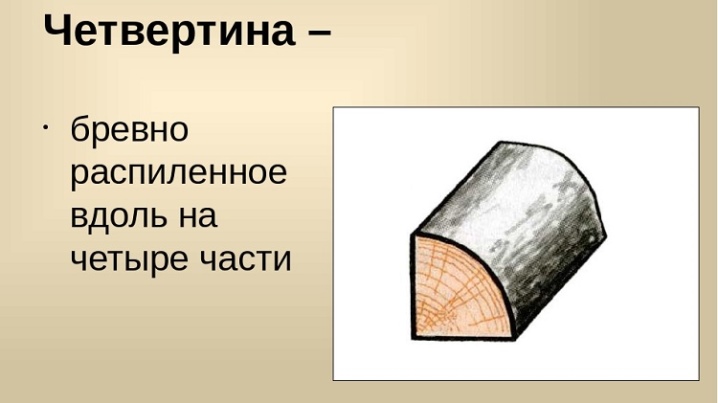

Quarters

These are parts of a tree that are obtained by two longitudinal cuts of logs through the center into 4 equal parts. They have 2 sawn off mutually perpendicular sides and are used for the production of some lumber, joinery and moldings.

Beams

This is sawn timber, the dimensions of which in cross-section along both axes are more than 100 mm. Made from hardwood. It is used to create beams for supporting structures in the construction of bridges, ships, log houses and interfloor floors.

Bar

Lumber, the dimensions of which in cross-section along both axes are less than 100 mm, and the width is not more than twice the thickness. When creating them, the same standards are applied that are used in the production of boards.

Bars are needed for the manufacture of furniture and various joinery.

Board

This is sawn timber, the width of which in cross-section exceeds the thickness by 2 times or more. It has wide sides, which are called faces, and narrow sides, which are called edges. The faces are always processed by planing and grinding. Edges can sometimes be grooved by creating tongue-and-groove or tongue-and-groove connections.

There are several types of boards.

- Lining - a long board of small width and thickness.It is used for interior decoration of the room, it is attached to the batten end-to-end or through the grooves. Lining is the cheapest and most common type of decorative boards.

- Imitation of a bar or false beam. This is a kind of decorative board, which is distinguished by its large width, which resembles a timber. The edges of the product are always processed by grooving, so the material is attached to the batten through the grooves. Imitation of a bar has a more aesthetic appearance and a high cost in comparison with lining.

- Block house. This is decorative lumber made from the outer semicircular parts of the logs. In section it resembles a segment of a circle. The product is used for interior decoration of premises, imitating a log house with its appearance.

- Planken... A short analogue of the lining, which does not have spikes and grooves. It is made of moisture resistant wood species. It is used for decorating rooms, gazebos, balconies and loggias, saunas and baths, less often - building facades. Installed both vertically and horizontally.

- Parquet board. It is used exclusively for decorative purposes for laying the floor, less often for wall decor. It is installed in a limited area and is used to visually expand the space of the room.

- It is also worth mentioning slats, which are not a separate type of lumber.... These are elements that represent a narrow thin board or flat wooden block and are used for decorating rooms, equipping balconies, gazebos and terraces, building wooden stairs and boxes.

- Another term that novice builders often come across is molding. These are products with a large length and relatively small cross-sectional dimensions. They are intended for decorative finishing of premises. These are long boards of any kind, wooden skirting boards, decorative profiles, as well as door and window frames.

- Sleeper... This is a short lumber of large width and thickness, in cross-section resembling a trapezoid with rounded sides. They are made from coniferous wood. They are used in the construction of railway tracks.

- Croaker or obapol... The side part of a log that has one sawn and the other non-sawn surface. Previously used for the construction of lathing or picket fence.

Today it is considered a waste product and belongs to sawn timber.

Applications

The performance properties of lumber allow them to be used in various fields. In accordance with GOST 8486-86, used for the manufacture of wood products, there are several categories of use of wood products. Construction - is the main consumer of sawn timber, where they are used mainly for the construction, repair of load-bearing and supporting structures of frame and log houses, for roofs, stairs, windows and doors.

Various types of wood in private construction are used for finishing works, construction of summer cottages, saunas and baths. Furniture factories use blanks to create decorative wood structures, as well as to manufacture furniture. For similar purposes, products of 1-3 grades are usually used. Products of the 4th grade can be used to create containers, packaging and boxes, as well as for auxiliary building structures - scaffolding, temporary wooden supports, sheds, platforms and pallets. It is not suitable for other purposes.

Mechanical engineering - in this area, lumber is used for the manufacture of wooden structures for equipment and machinery in carriage building and agricultural engineering. V automotive industry - to create trailers and semi-trailers, truck platforms. In shipbuilding - for covering boats, boats, ships and their decks. In mechanical engineering, wood of selected or 1-2 grades is used. The use of low quality wood is unacceptable when creating such structures, especially in shipbuilding.

The areas of application of sawn timber are very diverse. With proper care, wood in any room will create a calming environment, moreover, it will significantly improve the parameters of the microclimate. Use this practical material in private construction to fully experience all of its natural beauty.

You can also consider wood-polymer composite (WPC). This is a cross between a board and plastic, which took all the qualities of natural wood processing and does not support all negative factors such as rotting, splinters, insects.

The comment was sent successfully.