Dimensions of HDF sheet

There are quite a lot of different building materials on the market now, but wood-chip panels occupy a special place. They are used both in finishing works and in decorating premises. Today we will talk about a rather interesting type of these plates - HDF. Although they appeared not so long ago, they have already managed to gain popularity in this niche.

What is the thickness?

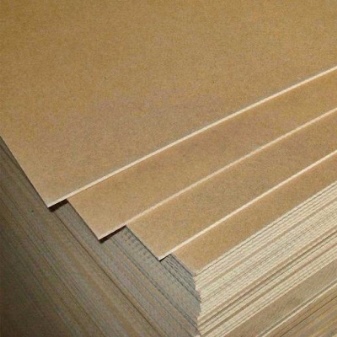

The name of these sheet panels comes from the first letters of the English expression High Density Fiberboard, which translates into Russian as “high density fiberboard”. The production of this material is similar to the production of other panels from sawdust and shavings. But for the production of HDF, the most environmentally friendly waste from sawmills is taken, in which there are no toxic substances and formaldehyde resins.

At this stage, two types of such plates are produced.

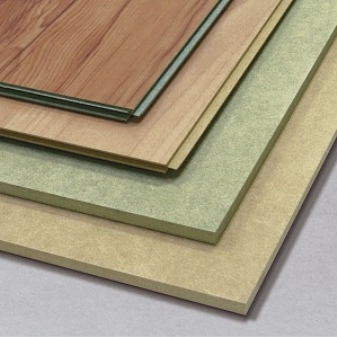

- Sanded. After manufacturing, the surface of the product is sanded for further painting or varnishing. Partitions are made of such plates, they are used as a substrate before laying laminate, etc. They are also widely used in furniture production, from these panels excellent bottoms for drawers, back walls of cabinets or cabinets and much more are obtained.

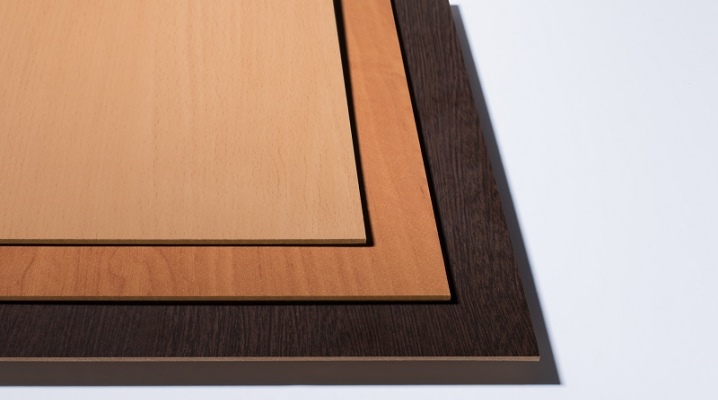

- Decorated (varnished). Obtained by priming and painting sanded panels. Then the main color is applied, imitating natural wood. It is an ideal material for the manufacture of cabinet furniture and doors.

In order to improve the properties of the panels, you can make them laminated. For this, melamine resins are heated, which, during heating, spread over the surface and, when cooled, form the thinnest film. After completing this process, the panels do not need additional processing. Although some take this look into a separate group, laminated ones are a subspecies of decorated ones.

HDF sheet size:

- in length they are 2440, 2500 and 2800 mm;

- width is 1830 and 2070 mm;

- thickness - 2, 3, 4, 5, 6, 8 mm;

- density - up to 1000 kg / m3.

The permissible deviations from the standard format can be no more than 0.2 mm and a maximum of 0.5 mm. The most common size is 2800x2070x3, but for the manufacture of some decorative elements, 2070x695x3 mm panels are produced.

Applications depending on dimensions

HDF boards are used in various fields.

- Furniture manufacturing. Most often they are used for drawers and back walls of high quality furniture: cabinet or upholstered.

- They make excellent interior doors to an office, a house, a summer cottage, a cafe, and so on.

- Due to their high strength and reliability, excellent partitions are obtained from the panels. Their dimensions make it possible to build them at high speed.

- Internal work. The small thickness of the slabs allows you to save more usable space in the room. At the same time, it is possible to mount them not only on the walls, but also on the ceiling, which significantly expands the list of areas of their application. They can be used as a backing for laminate flooring. The dimensions of the slabs contribute to an increase in the speed of work.

- Kitchen aprons. Various methods are applied to the slabs with a pattern, and from them an excellent replacement for tiles is obtained. Nice cost and absence of seams is a big plus in kitchen decoration. Custom sizes can be used to reduce material consumption.

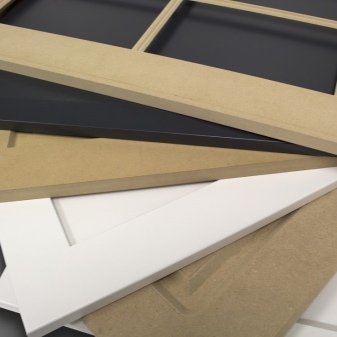

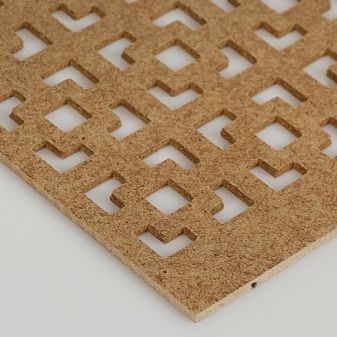

- Decor. Grilles are made from these plates to hide ventilation openings, picture frames.They also make excellent screens that cover heating radiators from prying eyes, holes are cut into them for free air passage.

- Finishing. Light weight and high reliability make it possible to use this material for covering the interiors of cars and passenger cars.

In most cases, the piece will have to be cut to obtain the right size components for finishing or decoration.

How to choose?

Selection of HDF boards is not an easy task. To make the right choice, you need to familiarize yourself with the technical characteristics of the material, its advantages and flaws in advance. The area of application of the panels is also of great importance. Let's start with the merits.

- High reliability. The panels are only 3mm thick and have pretty decent durability.

- Long term of use. Plates are able to serve for at least ten years, retaining their properties and appearance even in conditions when they are exposed to steam, fat or boiling water. Stains are easily washed away and the material looks like new.

- Environmental friendliness. Only natural ingredients are used in the production. Even when heated, they do not emit substances harmful to the body.

- A large selection of different colors, which allows you to choose them for any interior. You can also order photo printing, but it will cost more.

- Ease of installation. These products can be very easily fixed on the wall using self-tapping screws or glue, if they are used as an apron in the kitchen or as partitions.

In addition to the listed advantages, the price is pleasantly pleasing. These panels are significantly cheaper than wood and tiles.

There are also disadvantages - we will describe them.

- Only standard board formats are available, and there are few of them. If the panels are planned to be used to decorate a large area, then you will need to buy additional elements, and this is an additional cost.

- If the installation of the slabs on the walls was done incorrectly, then after a while they may deform.

- Since the products crumble during cutting, great care is required.

When buying, you should pay attention to the manufacturer. There are many unscrupulous suppliers whose products will quickly lose their valuable properties.

Recommendations for care and use

Products from trusted manufacturers do not need special care. It is enough just to remove all the dirt at once, without postponing it for later. This requires a damp cloth or sponge. In order for the material to serve for a long time, simple conditions must be met:

- always keep the panels clean;

- wash only with non-aggressive agents, in no case use metal brushes, etc.;

- do not place heating devices nearby;

- do not expose to strong mechanical stress.

After studying all the features of this material, you need to decide on the color. Usually panels imitate expensive natural wood, but there are options with photo printing. Then they are determined with the thickness of the slabs - it depends on where it will be used. For the manufacture of furniture or as an apron, you can use thinner varieties. And for the installation of jumpers in rooms, the arrangement of walls, floors or ceilings, you need to choose based on the expected loads.

When choosing, you need to take into account all these nuances. Due to its properties, HDF boards are preferable to panels from other similar materials (MDF or chipboard). And if the installation is also done according to all the rules, then they will delight you for a very long time.

In the next video, you will see the stages of the production process of MDF and HDF boards for Kaindl laminate flooring.

The comment was sent successfully.